What happened?

During Filament loading, either to the MMU unit or to the Nozzle, if the filament does not reach the SuperFINDA or is not detected, the printer will show an error.

How to fix it?

FINDA

Follow this guide to make sure that your superFINDA is working and has been properly calibrated: FINDA setup and troubleshooting.

Assembly

- Check if the filament has been grabbed by the idler/pulley. In case it has not, the filament is too far back.

- Make sure that the two spring screws on the sides of the MMU unit are properly tightened.

- Inspect the filament spool and the buffer for excessive friction or filament jam. Make sure the filament can move freely.

- Go over the assembly manual and verify if the barrel is in the correct orientation.

- Check the pulley gears for any filament remains, and check if the teeth are clean.

- Check that the corresponding pulley inside the MMU unit is properly aligned with the filament and is clean.

Selector

- Verify if the selector is in the correct position for the given filament number. After several unsuccessful retries, the selector will re-home.

- Check the selector for any filament remains and filament strings accumulated.

- On the MK3.5/S, MK3.9/S, MK4/S, and CORE One, go in the printer menu to Info - Sensor Info, and check if by passing a filament through the FINDA, the status will change.

- On the MK3/S/+, go to the printer menu to Support - Sensor Info, and check if by passing a filament through the FINDA the status will change.

Filament

- Make sure that the PrusaSlicer settings chosen match the filament you are using.

- Check if the filament needs to be dried: Drying filament.

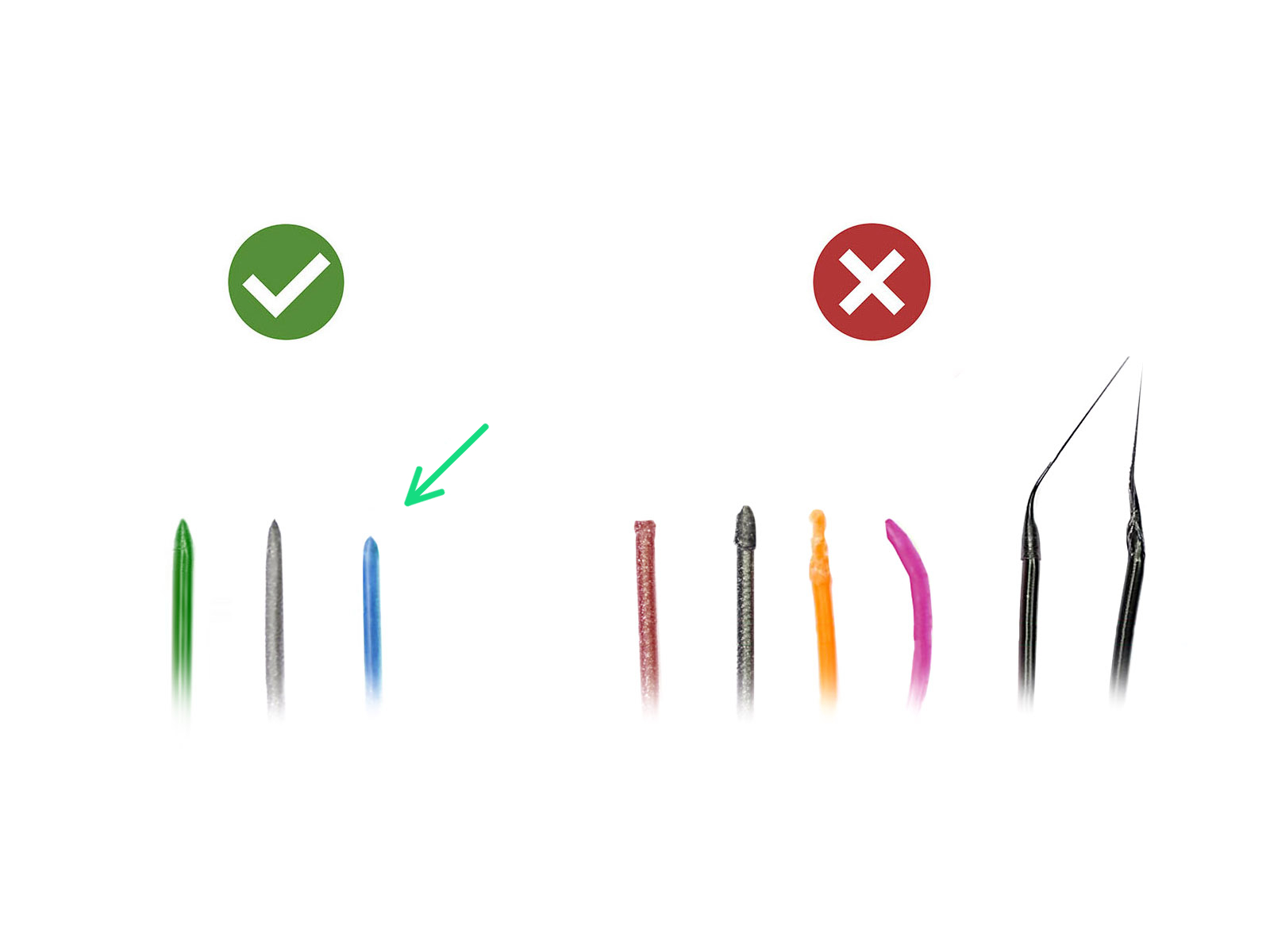

- The filaments must have a sharp tip in order to load properly into the printer. If the tip is deformed, bent, or larger in diameter, cut it off.

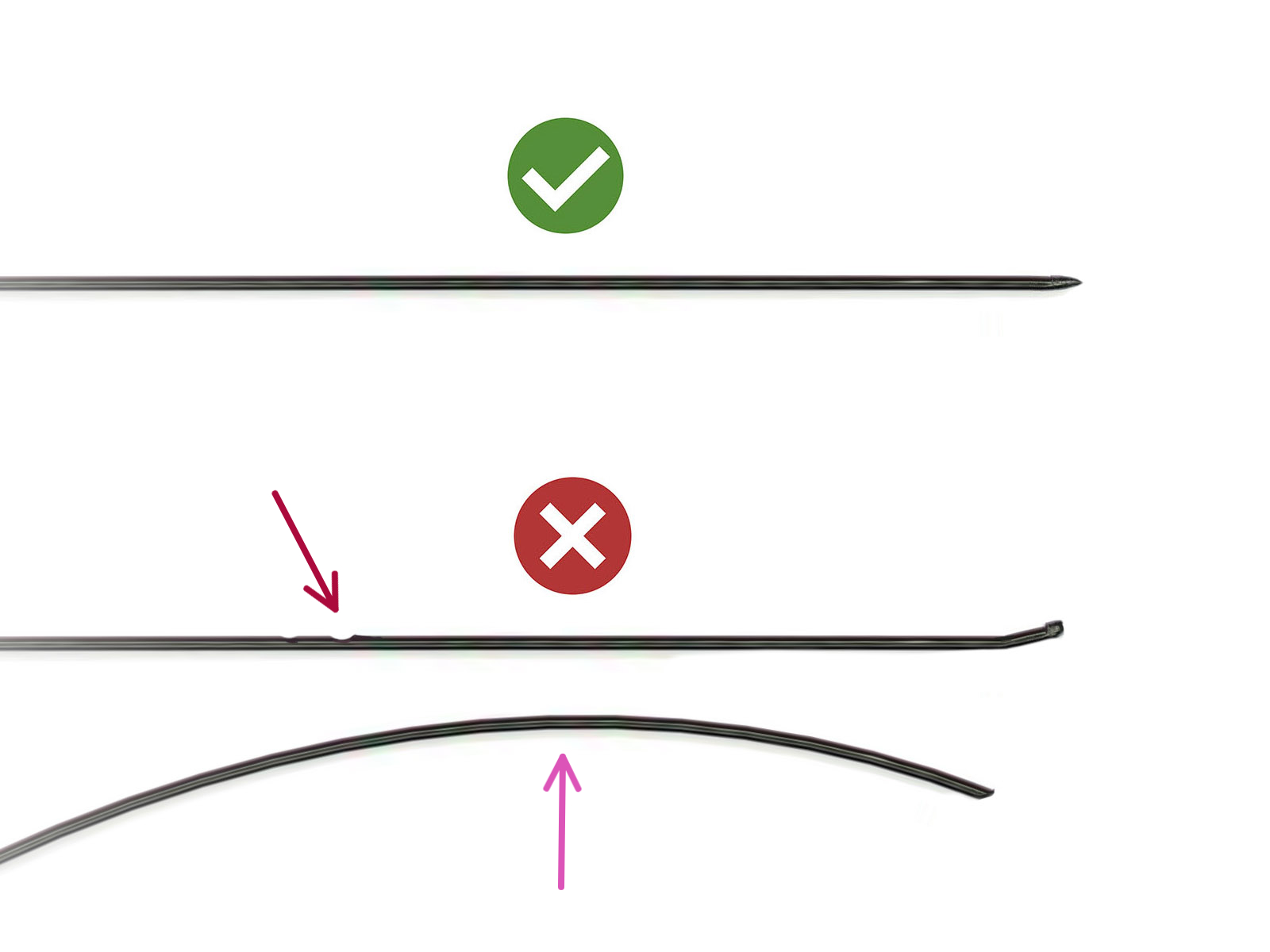

- Inspect the last 40cm (15") of each filament. Make sure there are no dents in it.

- If the filament is still not being pulled, check the assembly.

|  |

Was this article helpful?

This action is available only to registered users. Please log-in.

6 comments

If I could move the 1.idler the side, 2. unload the filament, 3 cut it... And 4. reload it.. I could save the print.

At a minimum move the idler put of the way... Please.

Why couldn’t I just say “keep going but use the next roll” like I had originally instructed it to do?

Had to cancel a huge print what a waste, guess I won’t be doing this again.

Like printers of old, make sure you have plenty of filament, babysit it, and waste a large portion if I you don’t think it’ll be enough.

Opening the mmu3 and using a tiny magnet to get the set screw and locking the gear to the shaft fixed my feeding issues.

PS Prusa support was non-existent, so thanks again for posting!

Later I had another problem where I had too severe a bend in my PTFE tubing and the filament jammed due to resistance. Unfortunately there was enough filament in the buffer to trick both the MMU and Nextruder sensors into thinking it was fine. The only way I caught it was the wipe tower started looking like spaghetti.

We're still a long ways off from having a sensor that can actually see the line of filament coming out or seeing the tension of the filament in the system...at least I think we are. Are there systems out there that can do it?

Suggestion for Prusa. Make the motor system of the MMU strong enough to pull from the spool and reduce the size of the buffer. That way the MMU isn't just dealing with filament under no resistance and passing it to the Nextruder, which actually does the pulling. This way the system would detect a feeding issue and eliminate the second problem I had.