PPSU (polyphenylsulfone) is a technical thermoplastic material with excellent resistance to heat and chemicals and superior hydrolytic stability. The main characteristic of this material is the resistance to impact. It has a higher ductility and can withstand repeated sterilization cycles, making it more durable in applications involving mechanical stress.

It is ideal for applications requiring extreme stability and durability. Its properties include high mechanical strength, toughness, and wear resistance. With a temperature range from -100°C to over 200°C, PPSU is suitable for applications with extreme temperature resistance.

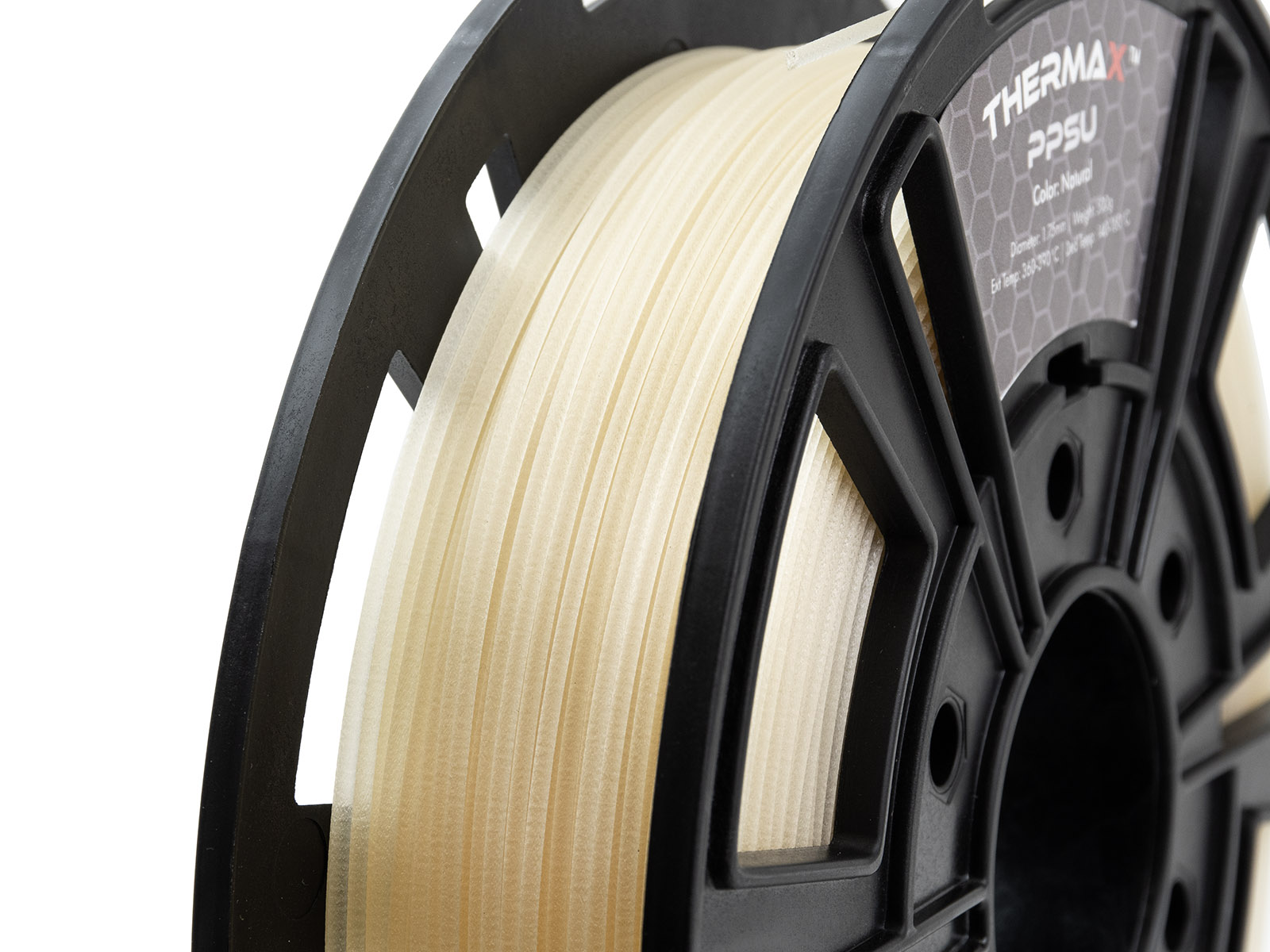

Recommended nozzle temperature: 370 - 410 ºC

Recommended bed temperature: 140 - 155°C

|

Pros |

Cons |

|---|---|

|

✔ Excellent temperature resistance |

✖ Higher cost |

|

✔ Good chemical resistance |

✖ Prone to warping |

|

✔ Resistance to radiation |

✖ Requires drying |

|

✔ Possibility of sterilization |

✖ Requires adhesives to increase adhesion to the |

| ✔ Self-extinguishing material |

✖ Removing supports can be difficult |

| ✔ Dimensional stability during printing |

|

Best use

Sterilized and chemically resistant components in medicine - casings, surgical instruments, pipes, valves. Additionally, connectors, relays, and aerospace components.

Tips for successful printing

It is essential to keep the filament dry, otherwise, its mechanical properties will significantly deteriorate. Despite the low moisture absorption, we recommend drying the filament for at least four hours at 110°C before printing and then using a dry box. Printing this material requires an enclosed and heated chamber with a minimum temperature of 65°C.

Heated chamber

An actively heated chamber is necessary to print this material with a temperature of 65°C or higher. A heated chamber is essential for printing high-temperature materials in FFF, due to several reasons:

- Prevents deformation: Maintains stable temperatures to reduce deformation and cracking.

- Improves layer adhesion: Supports stronger connections between layers.

- Preserves the properties of the material: Ensures proper crystallization and strength of the material.

- Prevents clogging: Prevents premature cooling of fibers and prevents problems with extrusion.

- Improves accuracy: Reduces thermal expansion and improves dimensional accuracy.

Print surface preparation

For printing, a special adhesive must be applied to the print bed (e.g., MAGIGOO HT) for the perfect first layer. We recommend using the adhesive in multiple layers.

Samples

|  |

|  |