The Original Prusa magnetic heatbed is designed to hold a removable, double-sided, flexible print sheet, specifically designed for easy removal of printed objects from the print surface.

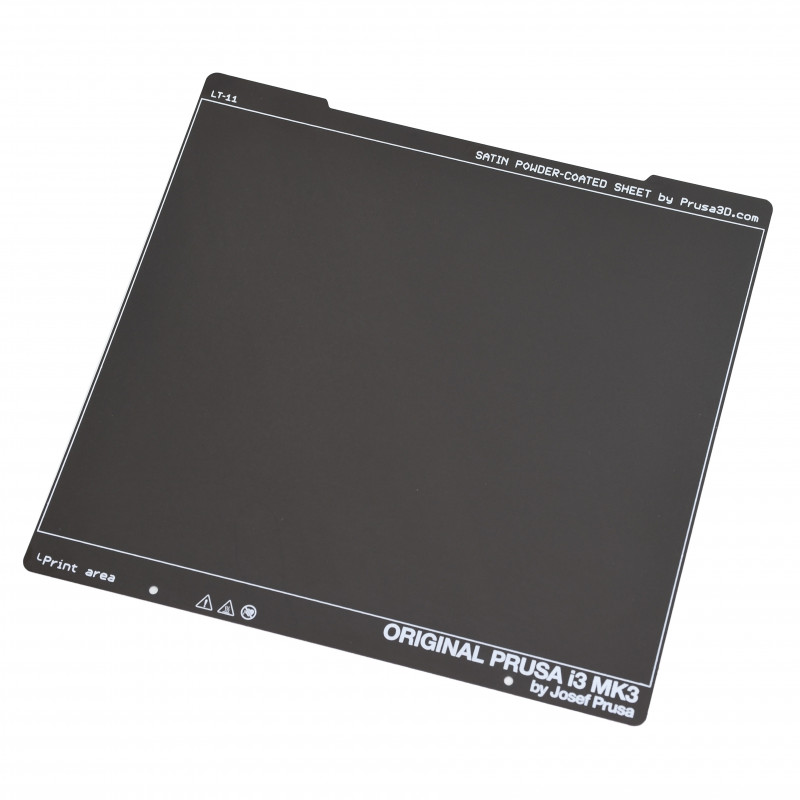

The Satin sheet further expands our line-up of print sheets. In terms of printing properties, the Satin sheet sits between the smooth and textured variants. Its fine powder-coated surface with a lightly textured matte finish offers an optimal level of adhesion, especially when printing PLA and PETG materials. It is fully compatible with a wide range of common and less-common filaments, such as ABS, ASA, FlexFill 98A, Polycarbonate (PC), and more.

|  |

| Satin Sheet (color may differ from yours) | The underside of a printed object |

Main attributes

- Suitable for both PLA and PETG.

- Lightly textured surface finish.

- Double-sided! Both sides can be used interchangeably..

- Prints automatically detach after the sheet cools down.

- Wide range of supported filaments, including advanced materials (PC Blend, Polypropylene…).

- Easy maintenance and good adhesion qualities.

Considerations

- Never clean the sheet with acetone! It will deteriorate the surface.

- Clean with ~90% IPA when the sheet is cold. If ~90% IPA is not sufficient, clean with dishwasher soap. Do not leave the sheet wet! It has an anti-corrosion layer, but it is still not recommended.

- Keep the sheet clean! Any grease will greatly reduce adhesion.

- The live Z value needs to be readjusted if you switch sheets. See Steel sheet profiles.

- Not scratch-resistant! Do not use metal spatulas, etc., to remove the prints. We recommend printing a plastic spatula, like this one.

- Small PLA prints may require a Brim.

- Apply a glue stick when printing with TPU or TPEE.

- Prints from ASA and PC Blend have a lower adhesion on satin compared to on the smooth sheet. Prints often require brim and/or shield (skirt "Draft shield" around the object is a feature in PS 2.3)

- PC blend works perfectly with the clean satin sheet; however, it might cause wear after some time. If you print PC often, a glue stick separation layer is recommended to prevent potential damage to the sheet.

- Fingerprints will mark the sheet. A good indication of where your sheet is dirty/greasy, and that you need to clean it.

- Some types of paper towels may leave traces on the sheet (fiber pieces).

Supported printers

Note that the sheets for the CORE One and the MK series sheets are interchangeable, just with different designs.

- CORE One

- XL (Also offered as Factory second)

- MK4/S, MK3.9/S, MK3.5/S, MK3/S/+, MK2.5/S (Also offered as Factory second)

- MINI/+ (Also offered as Factory second)

Filaments

We have done a lot of testing and compiled our results for you to use. To easily see how to prepare your sheet for any filament type, please see our Material table.

Prints don’t stick

If your print surface is perfectly clean and all grease has been removed by wiping it with a paper towel soaked in isopropyl alcohol ~90% and if the first layer height is set up perfectly, yet your print still does not adhere reliably to the print surface, check out First layer issues.

6 comments

Hi! Using a sharp blade can be risky. So, you can print a PETG object over it and try to remove it together.

If there is a way to get that thin layer of PETG or PLA off of any of the sheets I would be extremely greatful.

you can use 99% which is fine to use, we recommend 90% as 70% can leave residue and not clean everything. 90% works well, 99% will clean more, but it normally more expensive than 90% and is more readily available.

But be sure it is "pure", i.e. only other substance is water. Beware of IPA with detergents, perfume, or disinfectants.