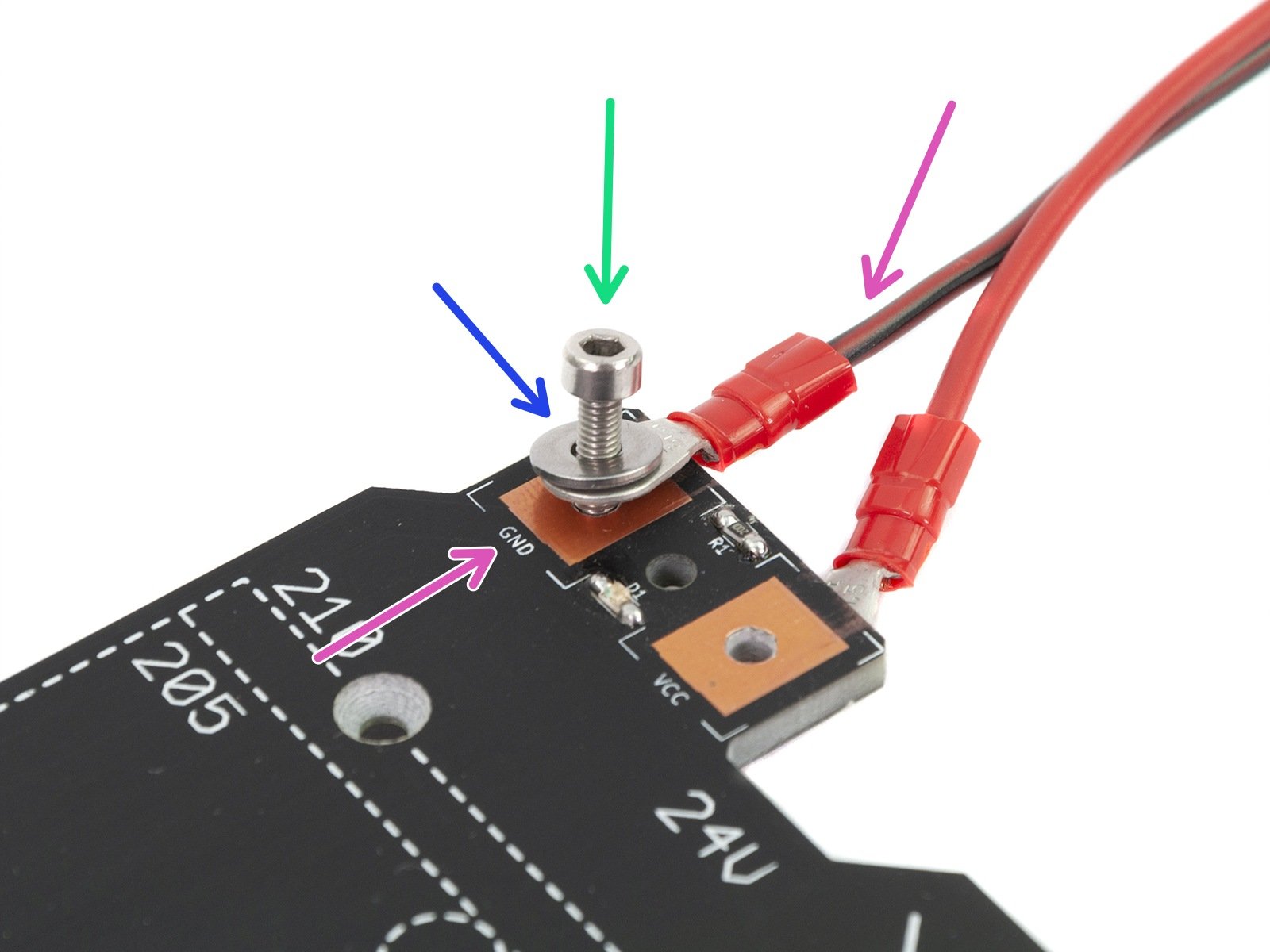

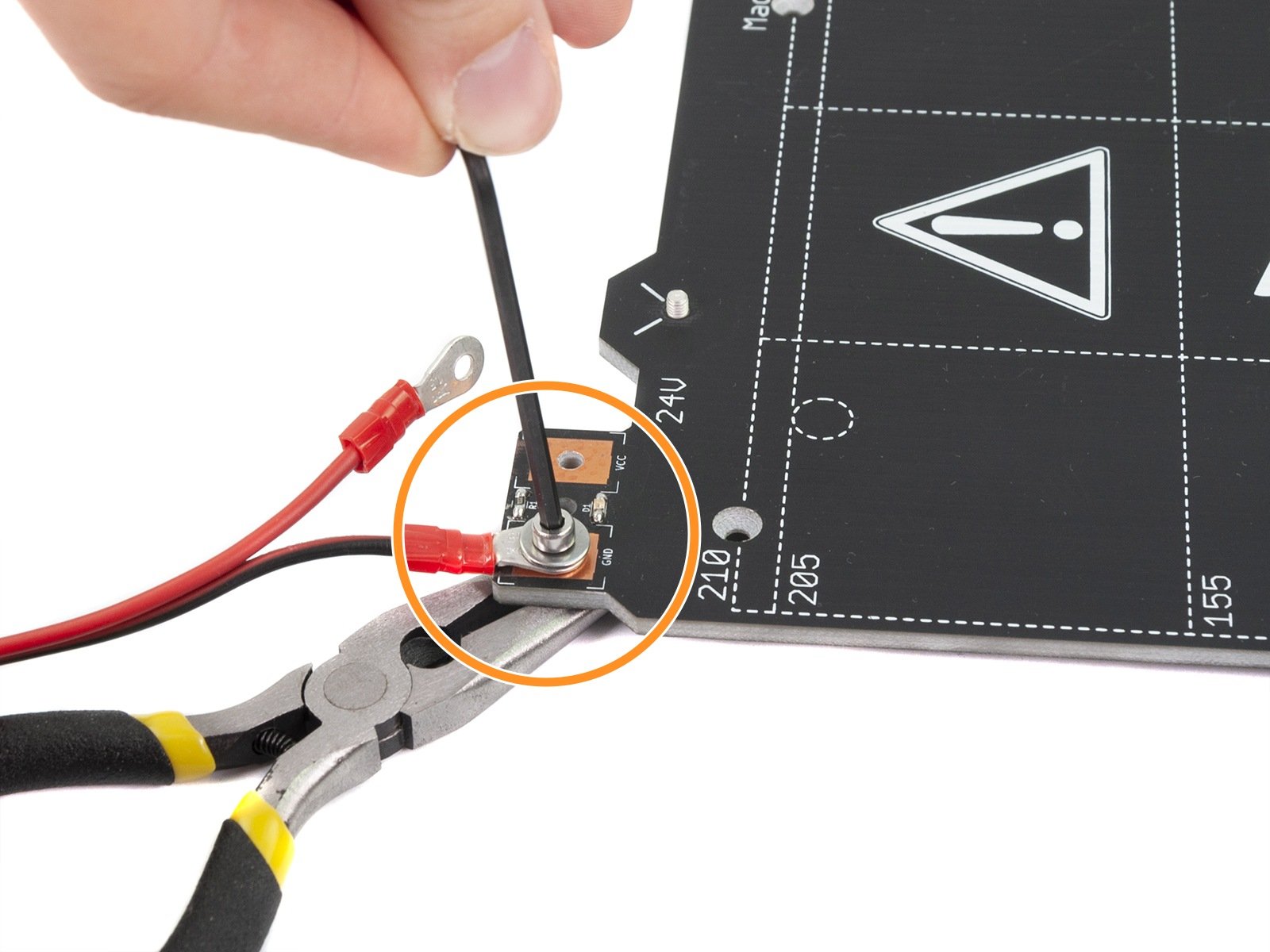

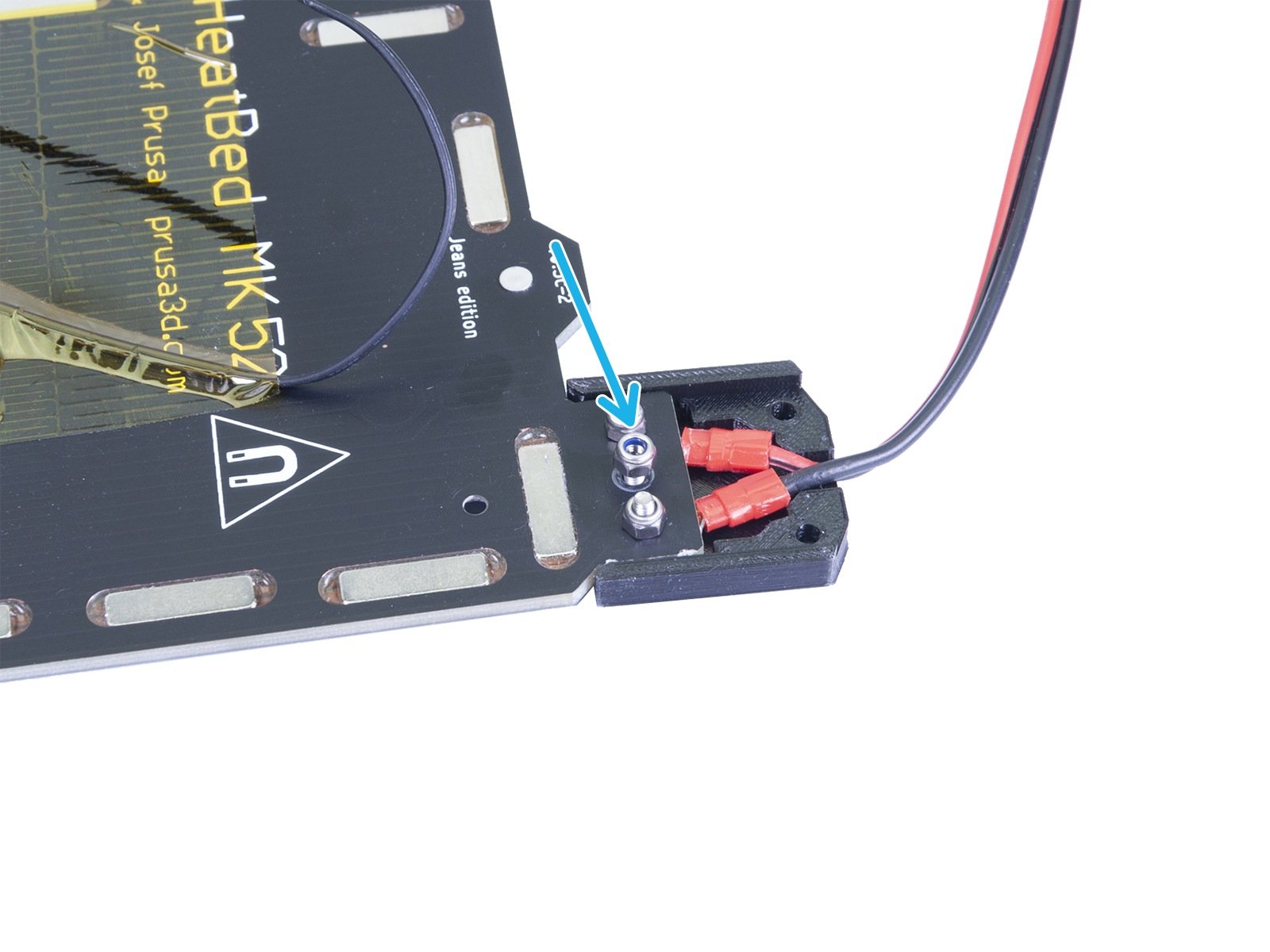

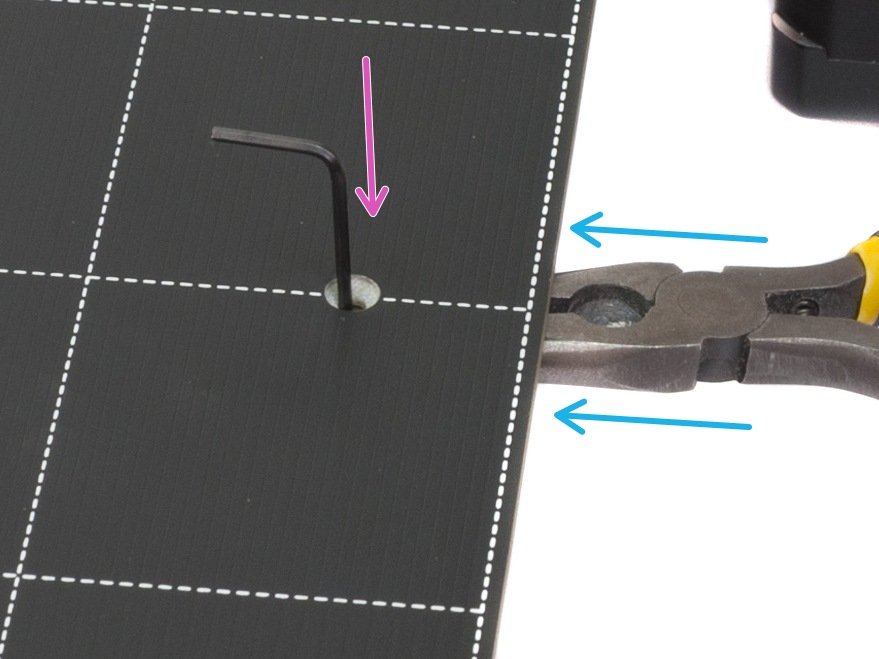

⬢Needle-nose pliers for the heatbed assembly

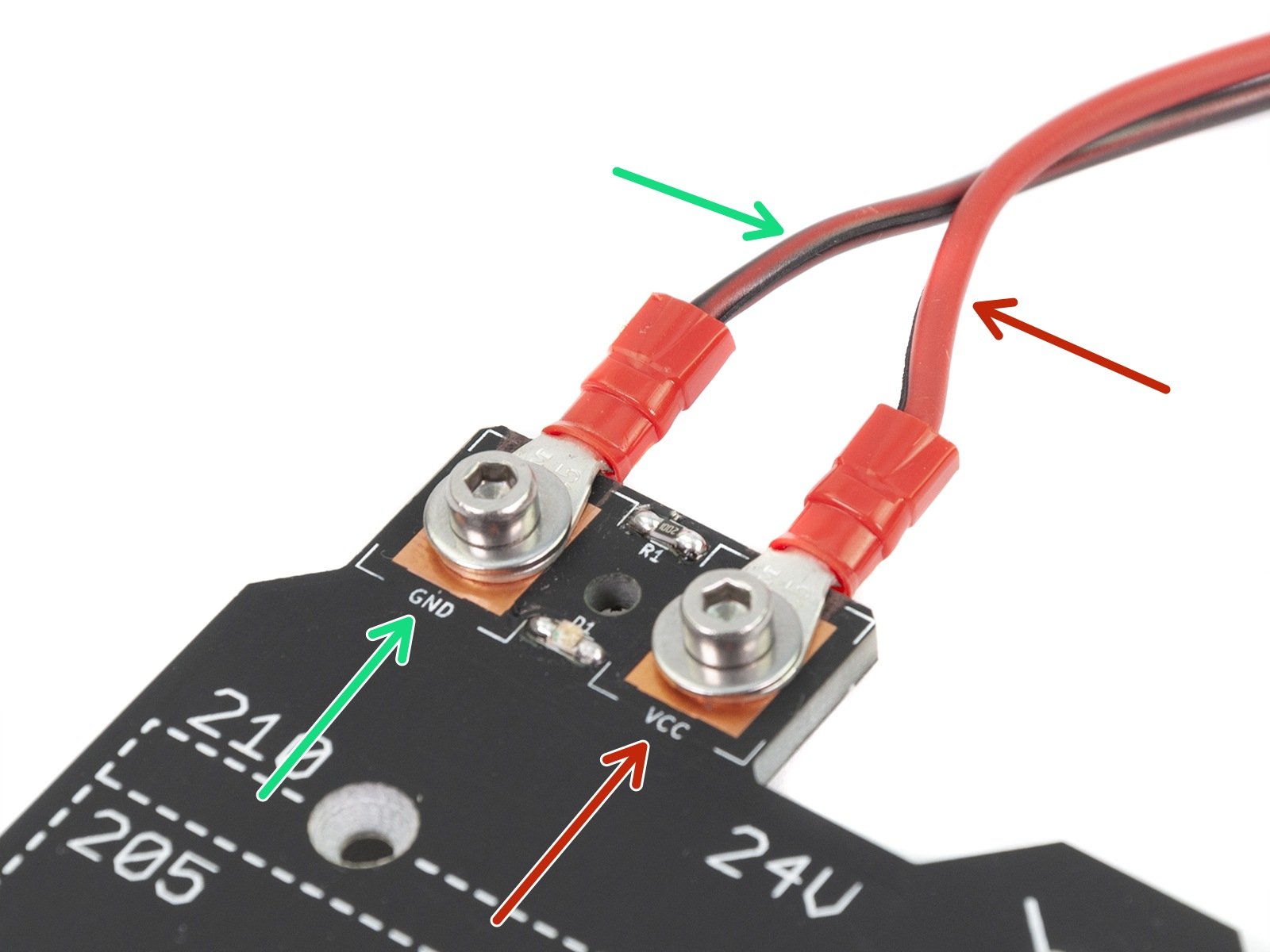

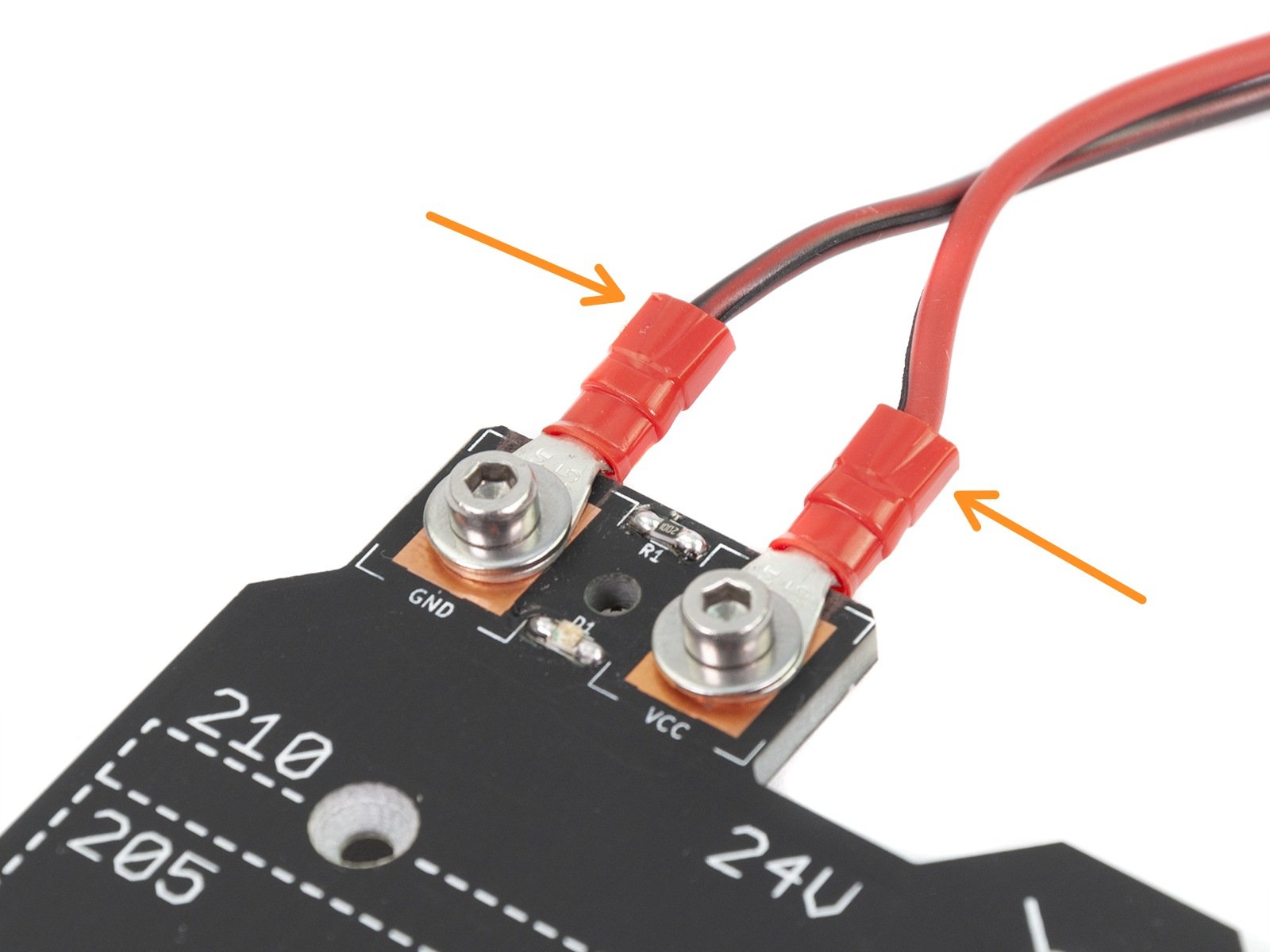

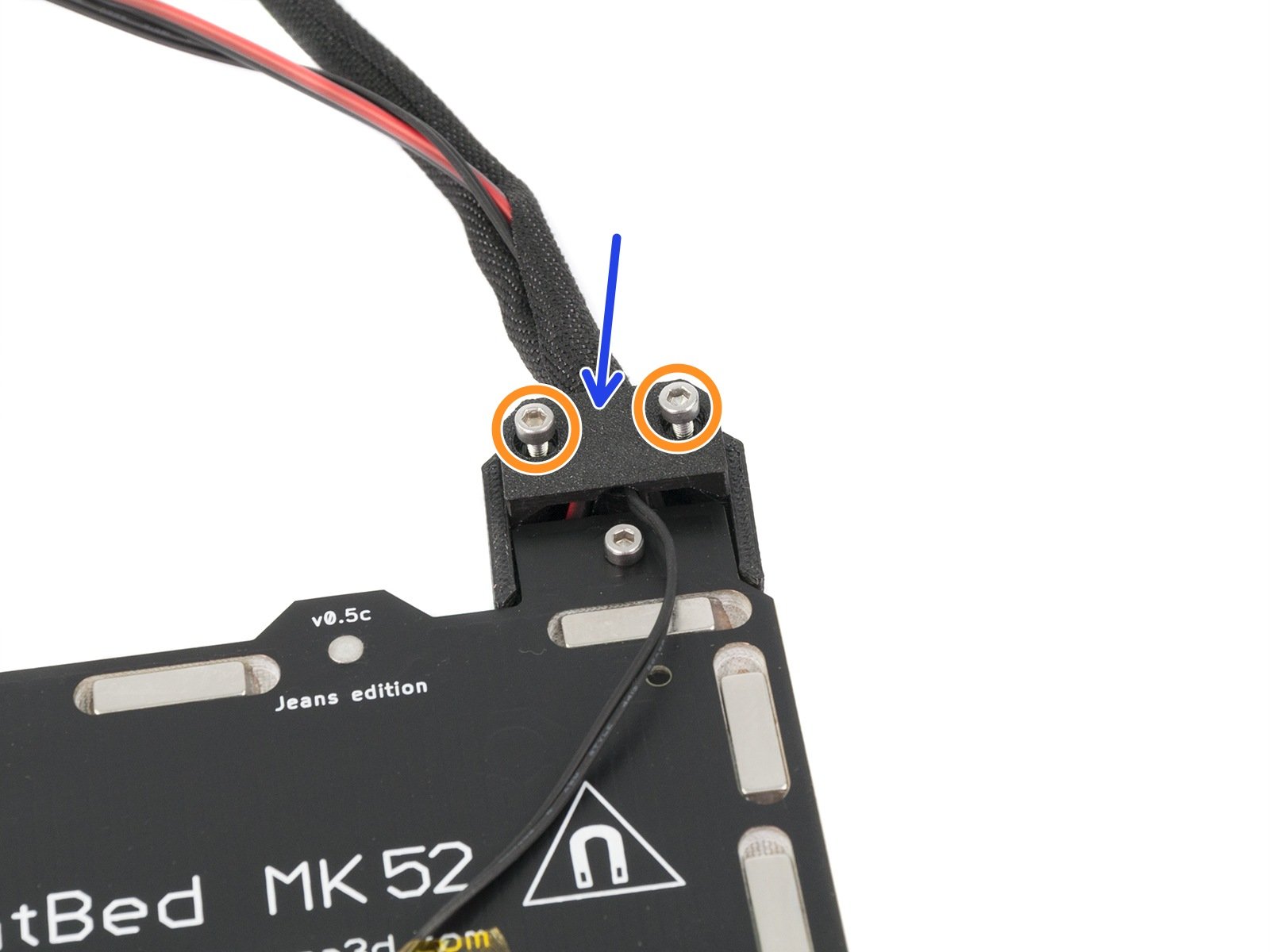

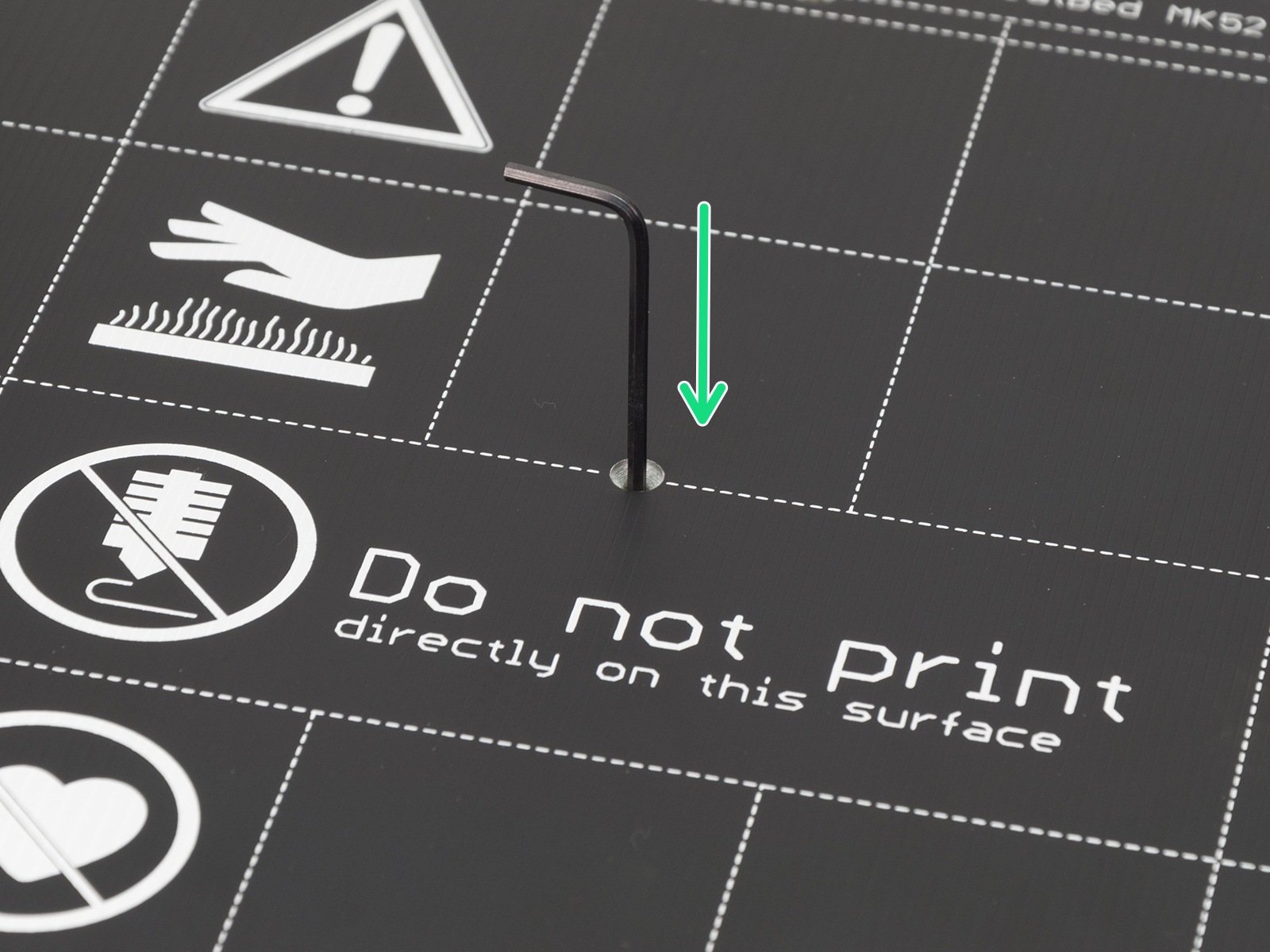

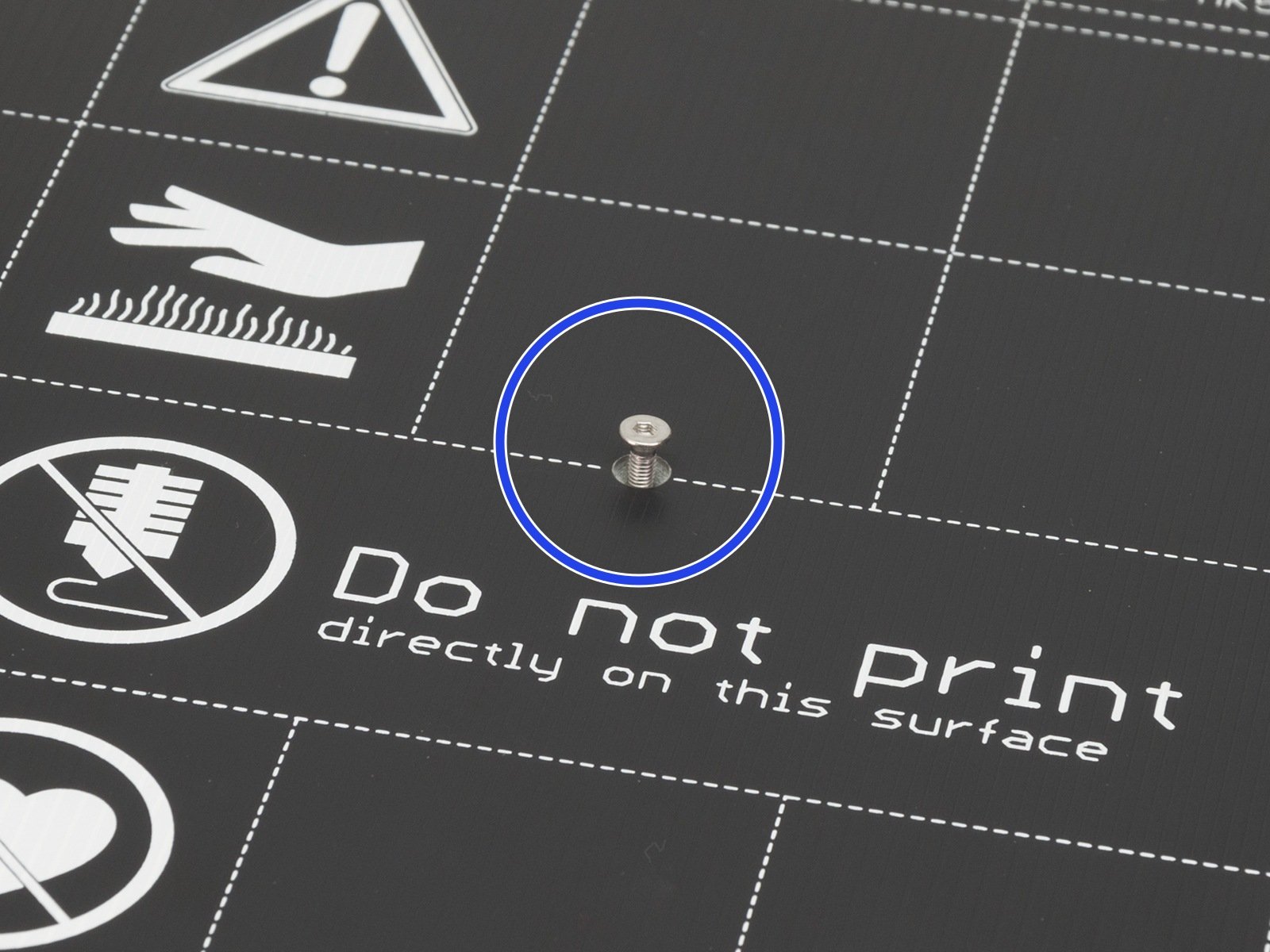

⬢2.5mm Allen key for M3 screws

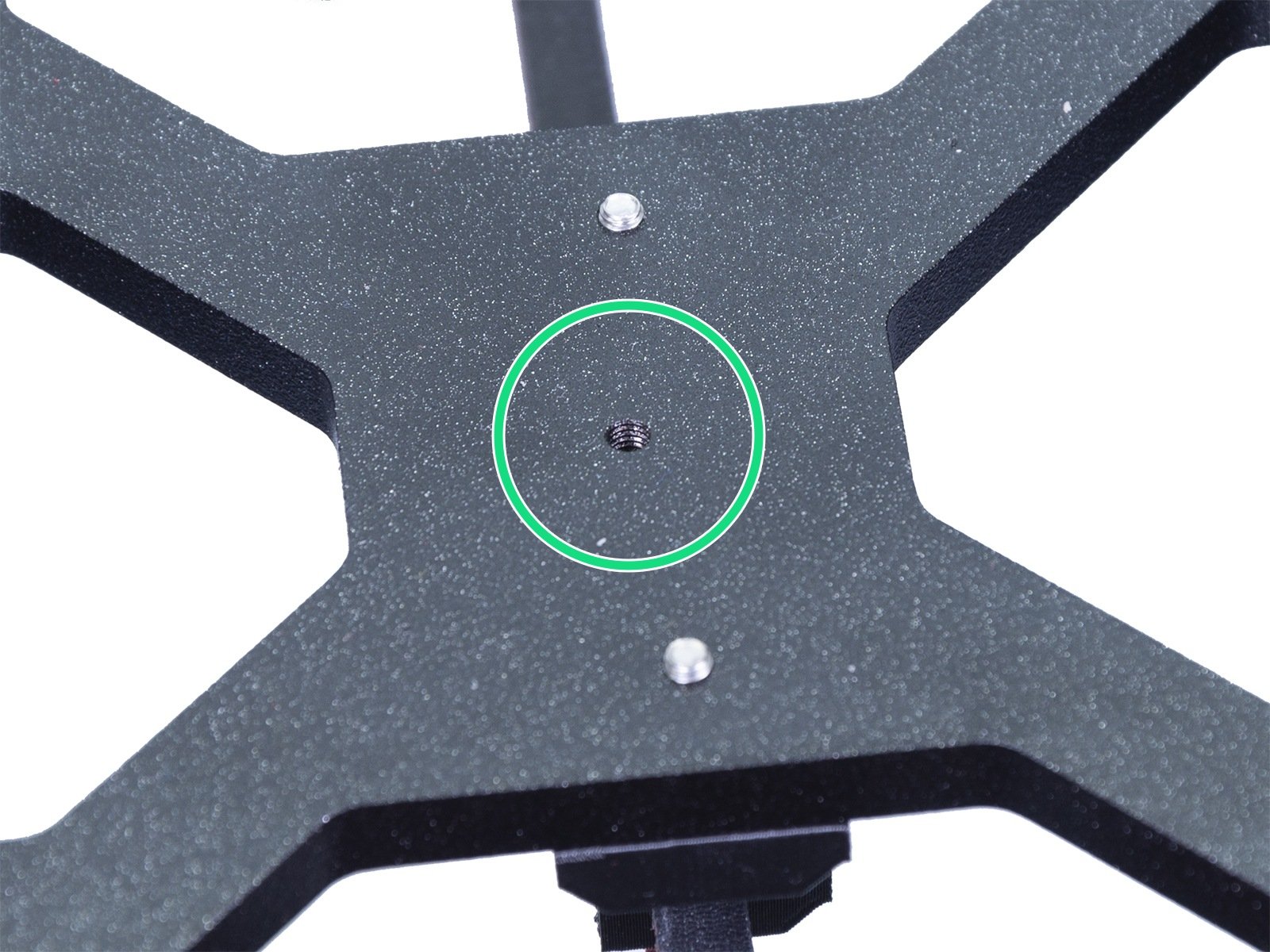

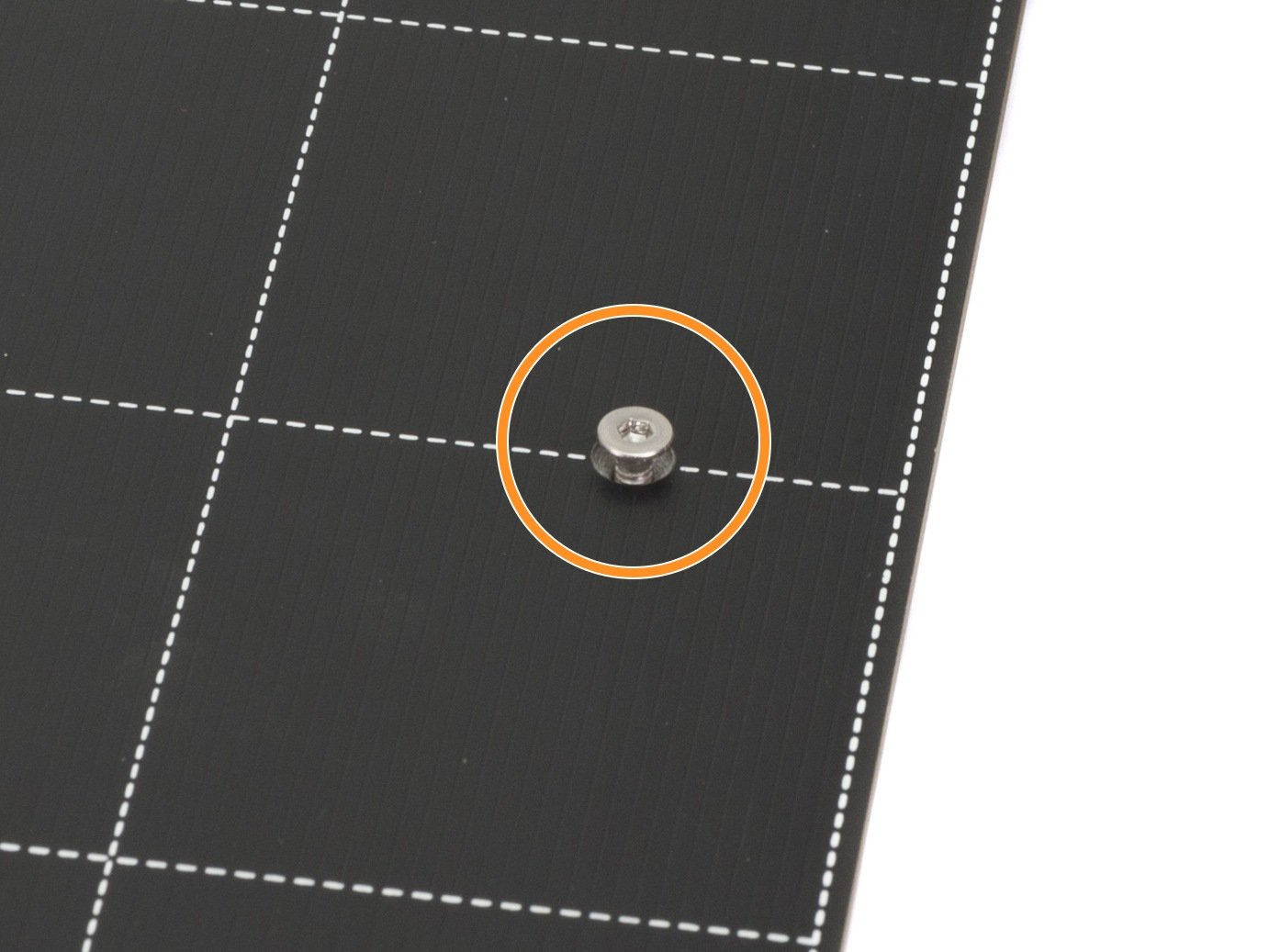

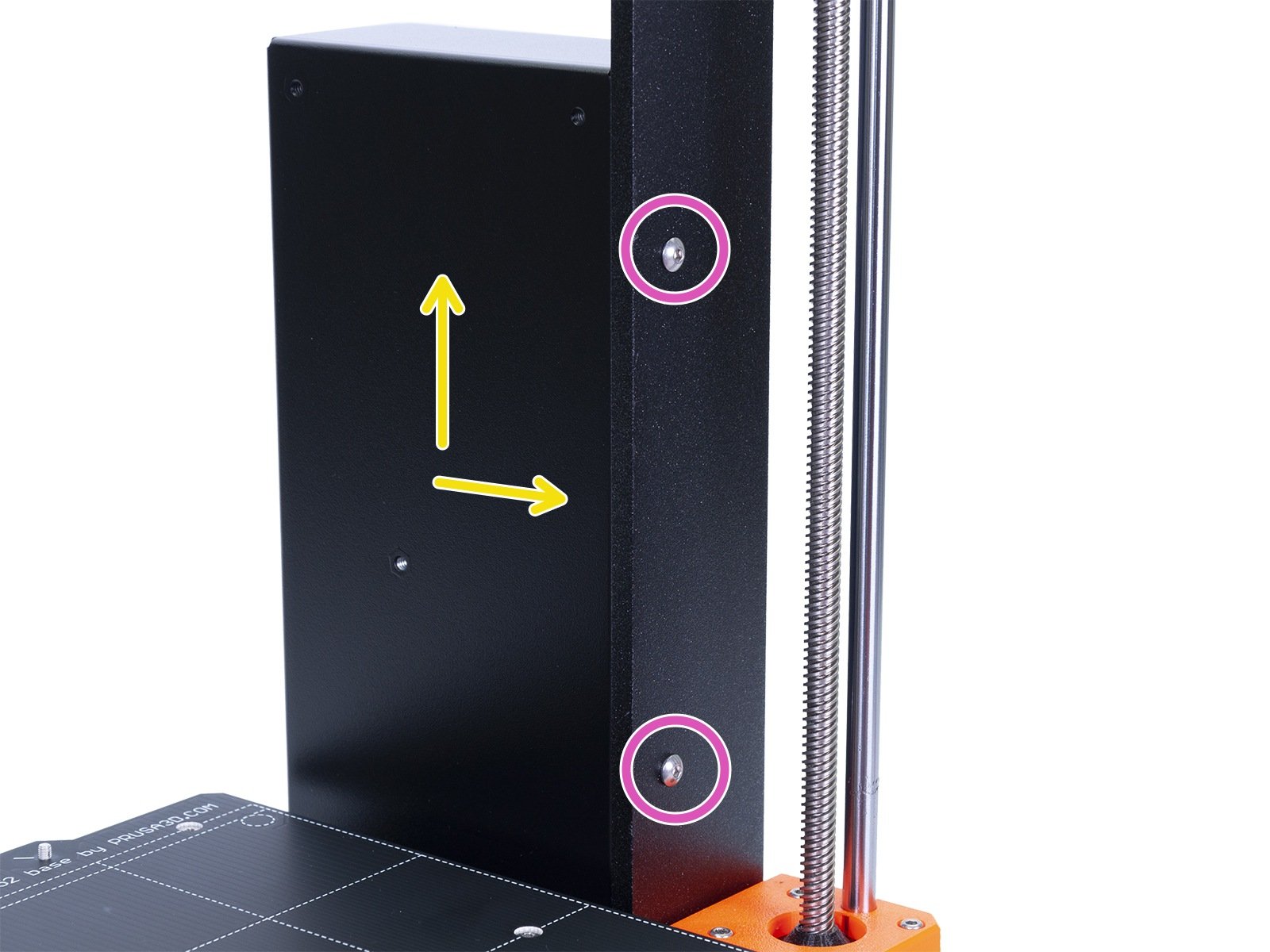

⬢2mm Allen key for heatbed alignment

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.