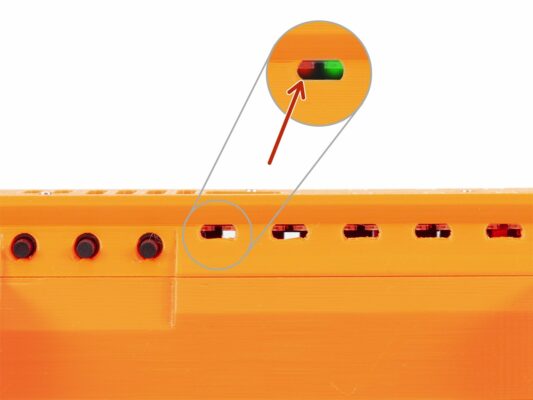

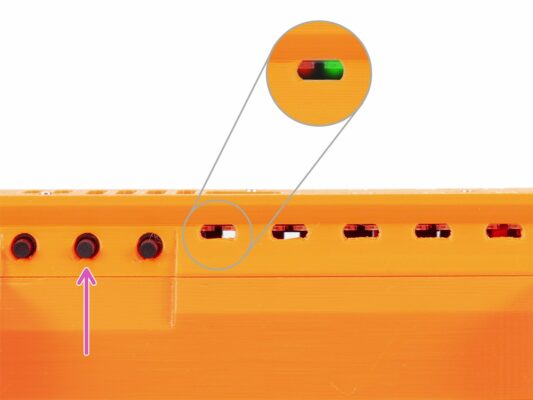

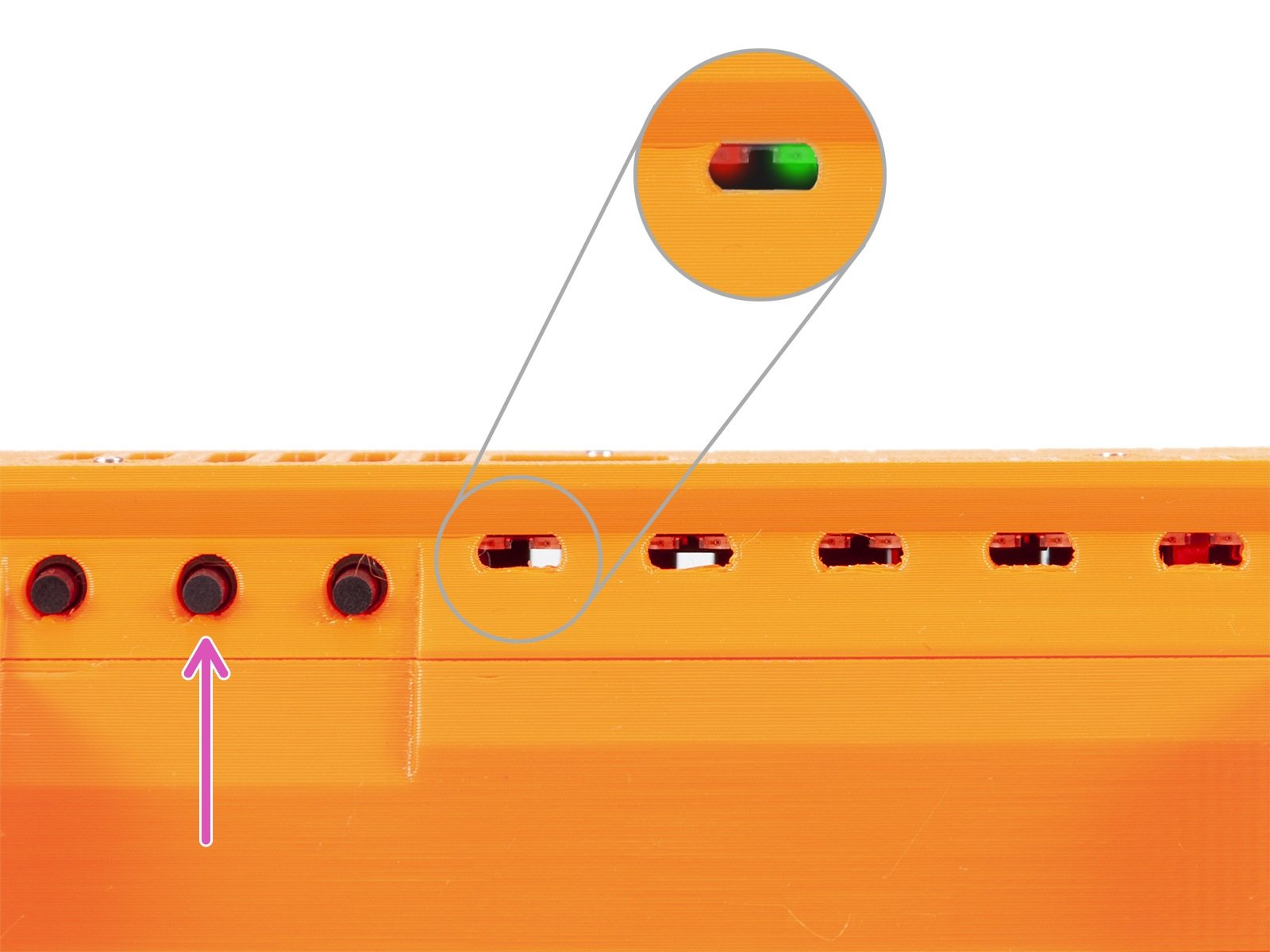

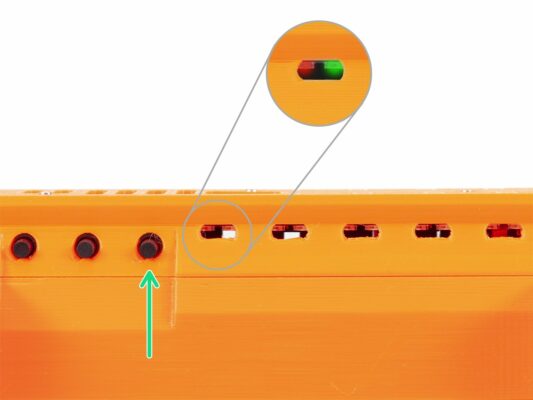

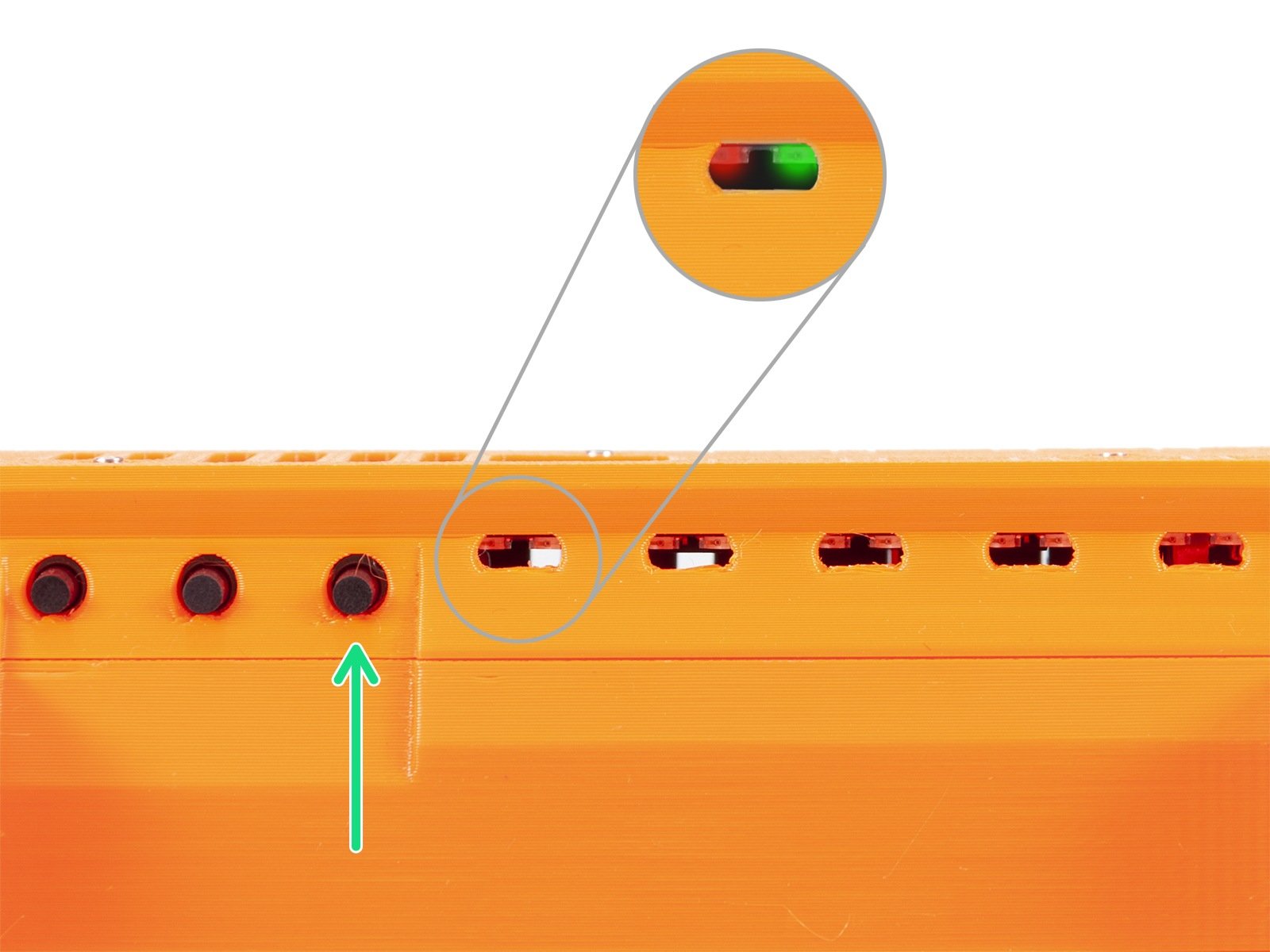

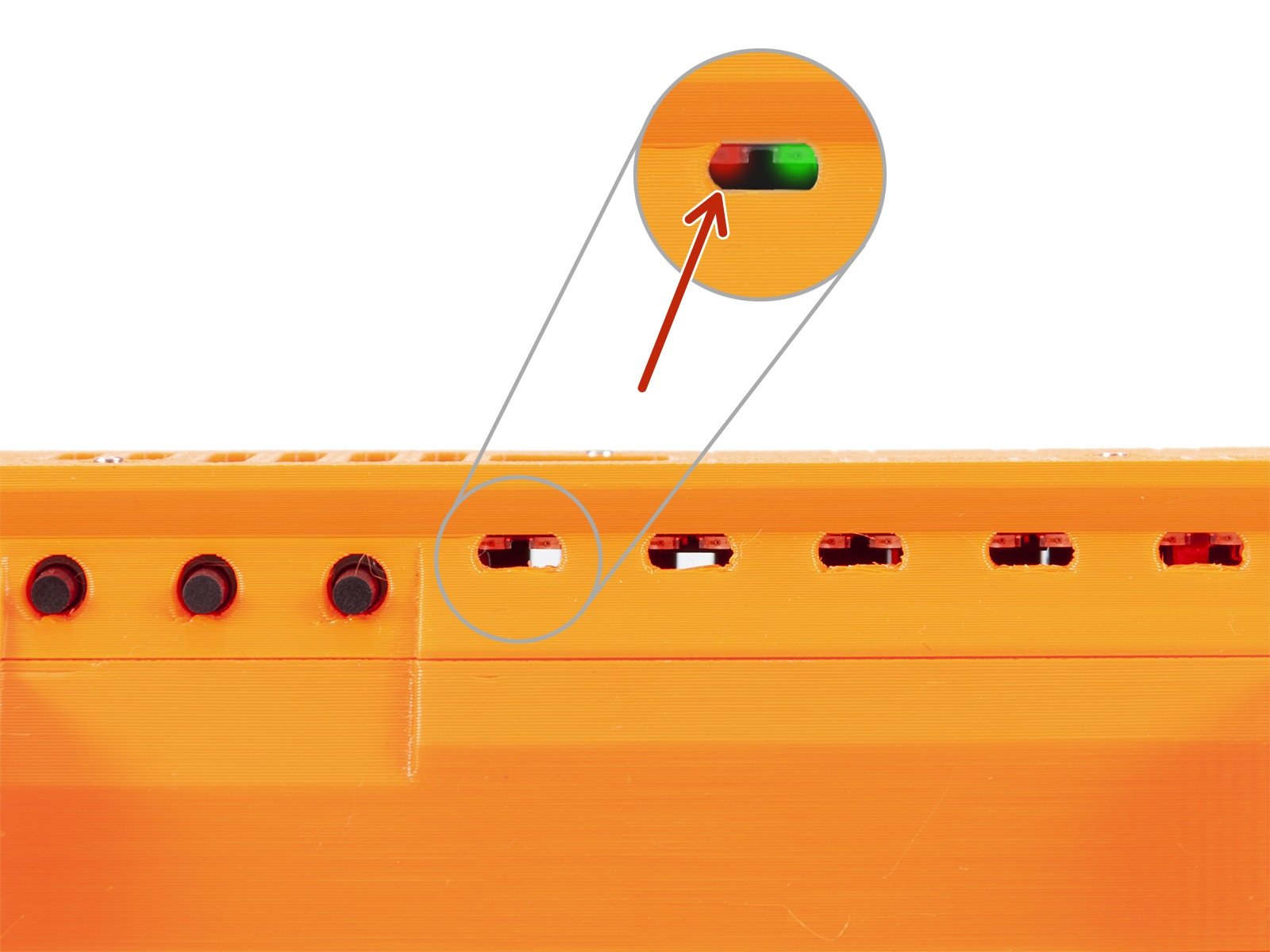

⬢During filament loading or unloading the filament can get stuck (jammed). The printer will try several times to fix it by itself, but if those attempts fail, it will light up LED above the affected filament.

⬢The LED will be flashing with RED light:

⬢Slow flashing - fault during filament load (moving the filament in the printer)

⬢Rapid flashing - fault during filament unload (moving the filament out from the printer)

Note: green LED lights up in case of successful filament load/unload.

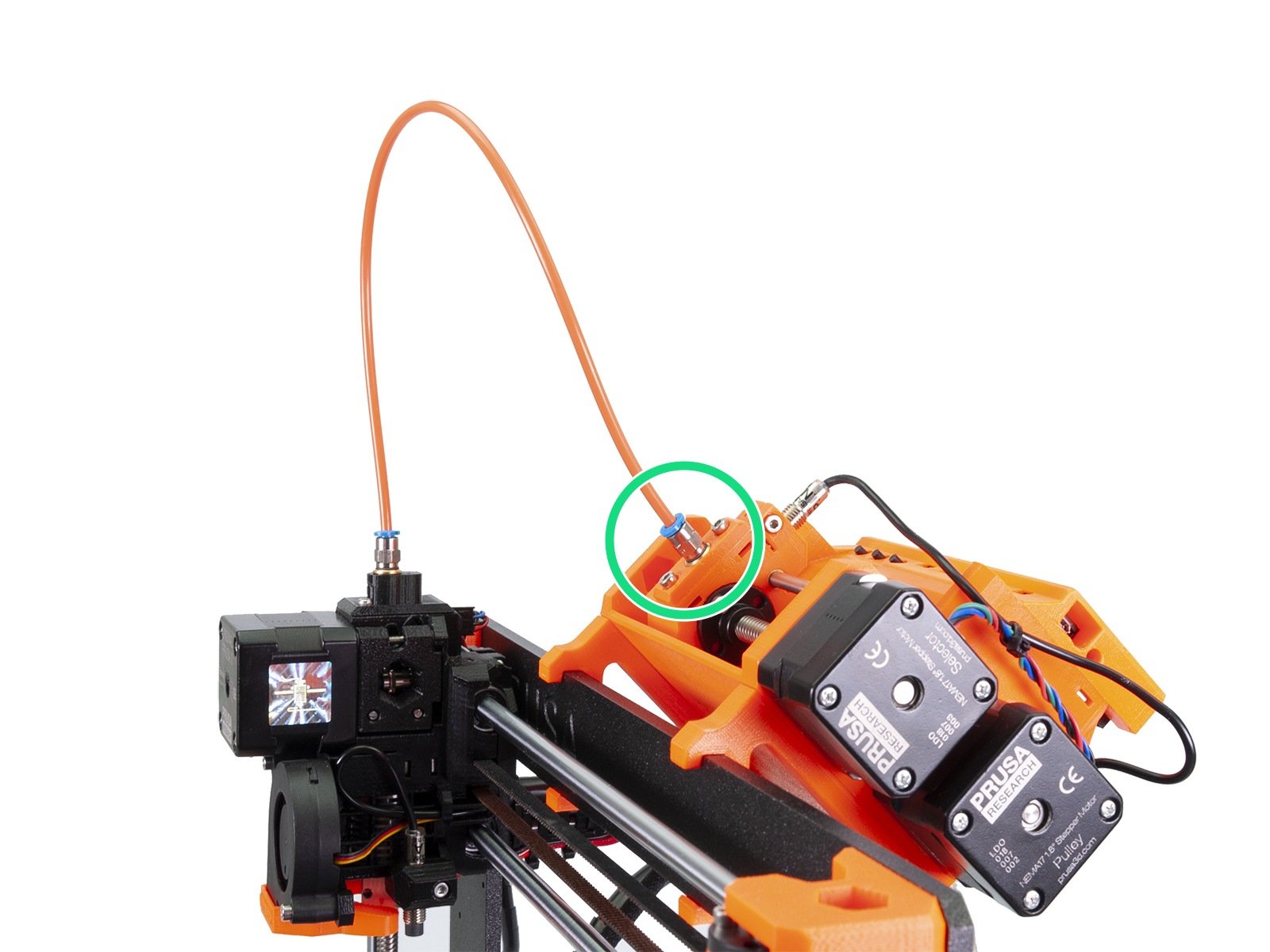

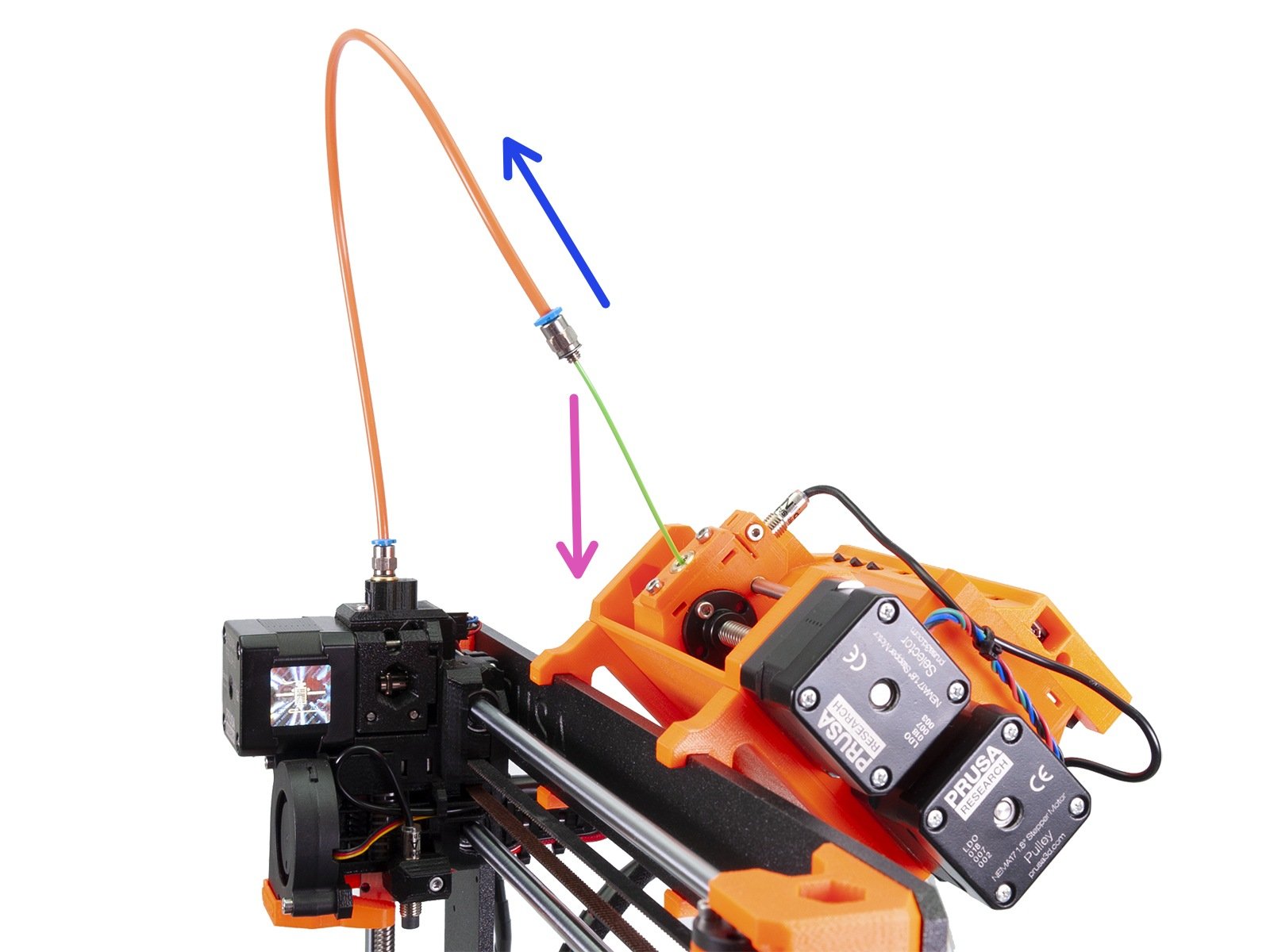

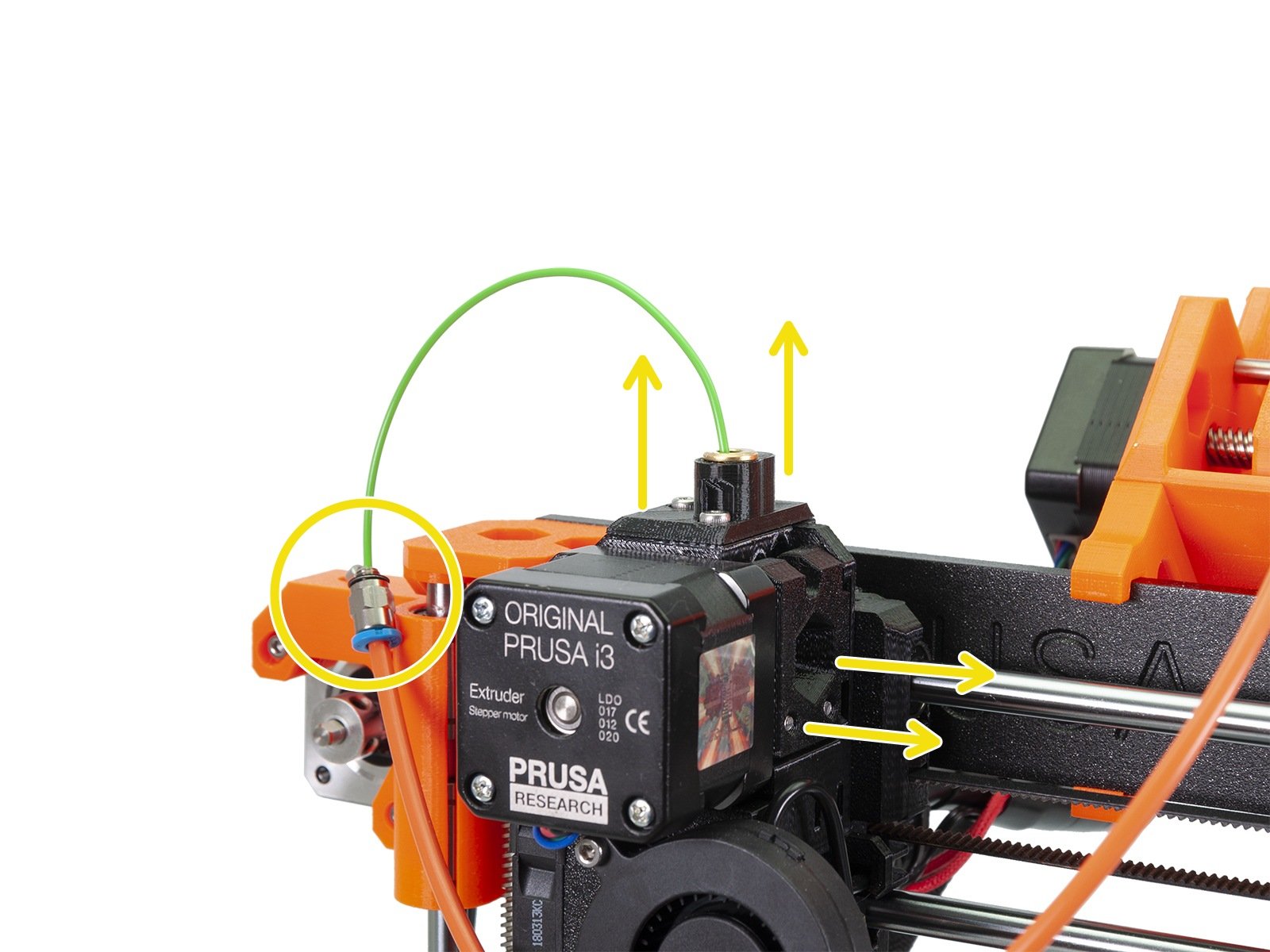

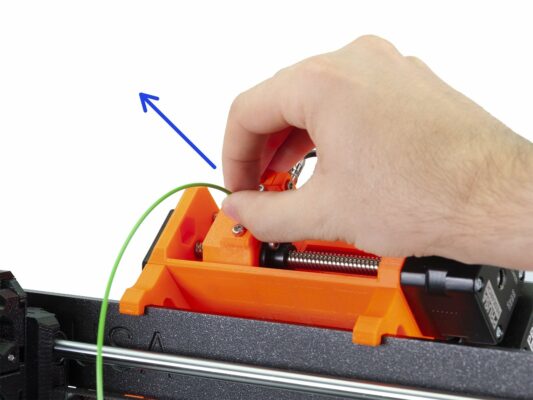

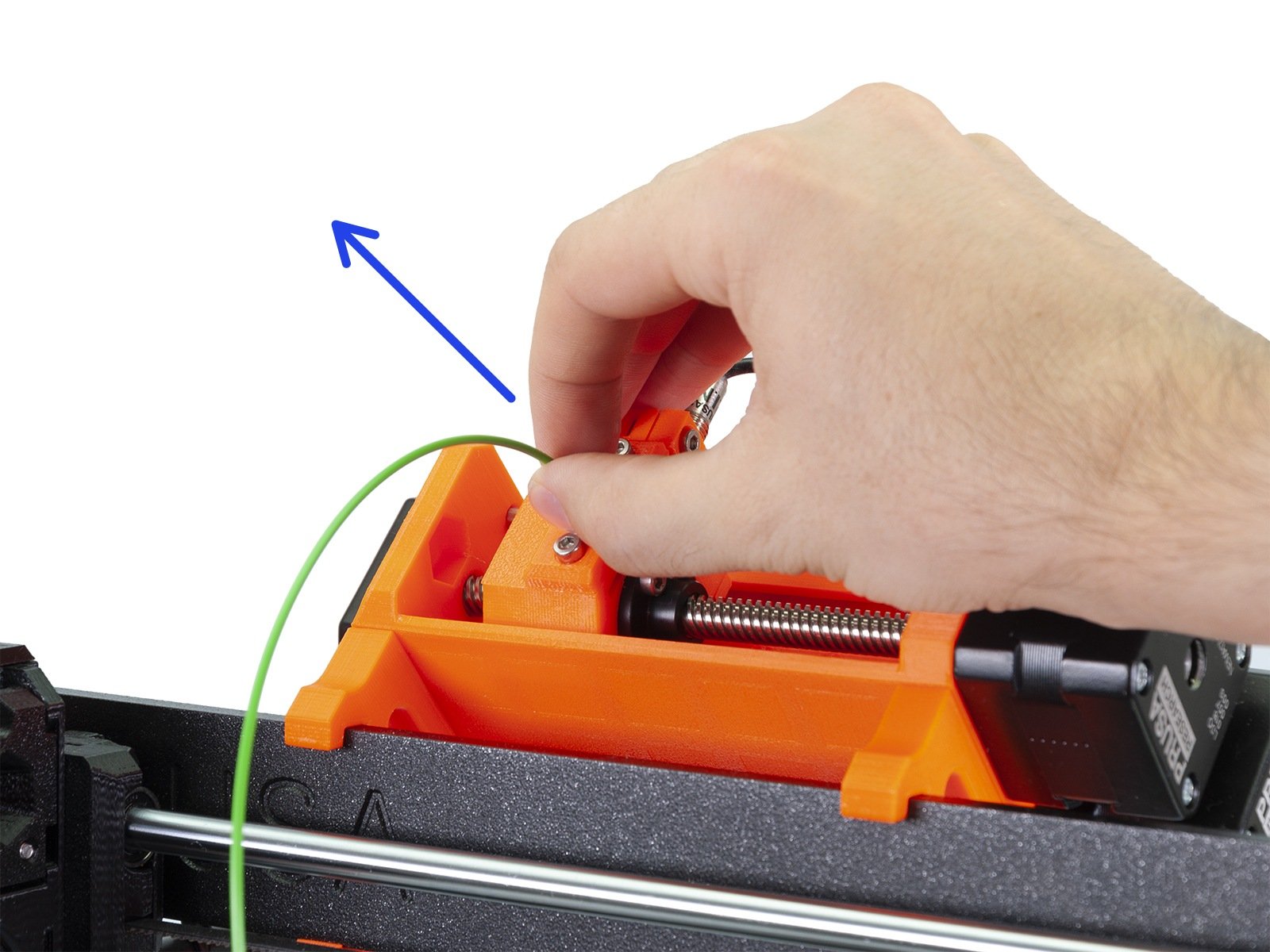

⬢As soon as the filament jam is detected, the printer waits for the user's action. The print is paused, no need to cancel it. Following steps will explain how to fix it and continue printing.