The Calibration failed error occurs once there is a problem with the calibration. The printer was unable to properly detect the calibration point/s and can not successfully finish the calibration. In order to operate the printer, you must find the source of the problem and fix it.

There can be five different error messages related to the Calibration failure:

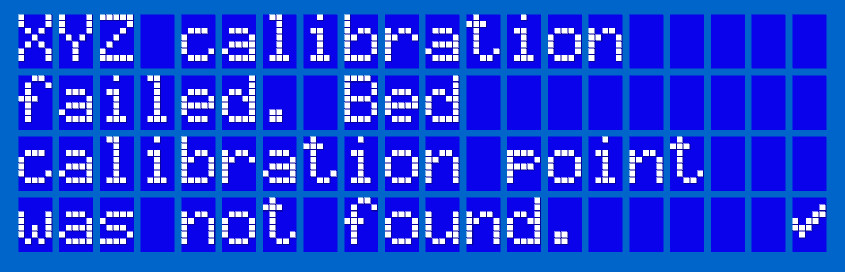

- XYZ calibration failed. Bed calibration point was not found.

- XYZ calibration failed. Please consult the manual.

- XYZ calibration failed. Left front calibration point not reachable.

- XYZ calibration failed. Right front calibration point not reachable.

- XYZ calibration failed. Front calibration points not reachable.

Troubleshooting

Bed calibration point was not found & Please consult the manual

Both of these error messages point to the same source. The printer was unable to find any of the calibration points. Therefore, there is almost for sure something wrong with the assembly. Don't re-assemble your printer just yet, but see the troubleshooting points of the following articles.

Left, Right, or Front calibration points not reachable

Unlike the other error messages related to the calibration, in this one, the printer was actually able to find some calibration points, but not all of them. However, troubleshooting remains the same. As that is the only way how to easily find out where the problem lies.

- Go to LCD Menu -> Calibration -> Auto home.

- Inspect where the PINDA sensor ends up. It must be within the First calibration point.

- After checking the 1st calibration point, move the extruder with your hand, to the other end of the heatbed and inspect the 2nd calibration point.

- If the PINDA sensor wasn't inside of any of the circles. Follow the instructions in the PINDA sensor misaligned.

7 comments

Hi Suzan! This article actually refers to the calibration on the i3 series printers, not MINI. Does the printer stop mesh bed levelling on the 4rd point before printing? You might want to contact support via prusa3D.com to resolve the issue.

XYZ calibration failed. Please consult the manual.but I cannot find what to do?

Hi Jack! What type of the printer you are using? Any upgrades, maintenance or modifications you have done lately?

Hi! Does the printer hit both X and Y endstops correctly? Make sure the printer is stock, MK52 heatbed, latest MK2.5S print head, there is no 3rd party accessory like a fan cover installed, make sure zip-ties do not interfere with the frame, Rambo-cover or the PSU. There are some different parts for the 2.5S and 3S/+: cable-holder on the back of the extruder has more clearance for the MK2x frame. There must be the endstop block installed to the bottom of the x-carriage. Make sure it is not molten. Check you have the correct Y-belt holder, not the MK3x one. Make sure the hotend is inserted correctly into the print head and the PINDA height is set according to [id=312|title=the assembly manual] (approx. 0,6mm above the nozzle.) - this is why it might fail the XYZ calibration too.

I also tried the Factory Reset multiple times as I was adjusting the PINDA probe.

Any other ideas I could try?

XYZ calibration failed. Please consult the manual.

Before installing the 2.5 upgrade kit, it was working fine, so I have no clue why it's not working... very frustrating.