When unloading the filament, the tip can have a large or irregular shape that is too big for the Bowden PTFE tube. You may hear some grinding sounds from the extruder as the printer is unable to pull the filament. It can then be stuck in the Bowden or hotend PTFE tube after the unloading procedure is complete.

To resolve this in the fastest way possible your approach can differ depending on where it is stuck:

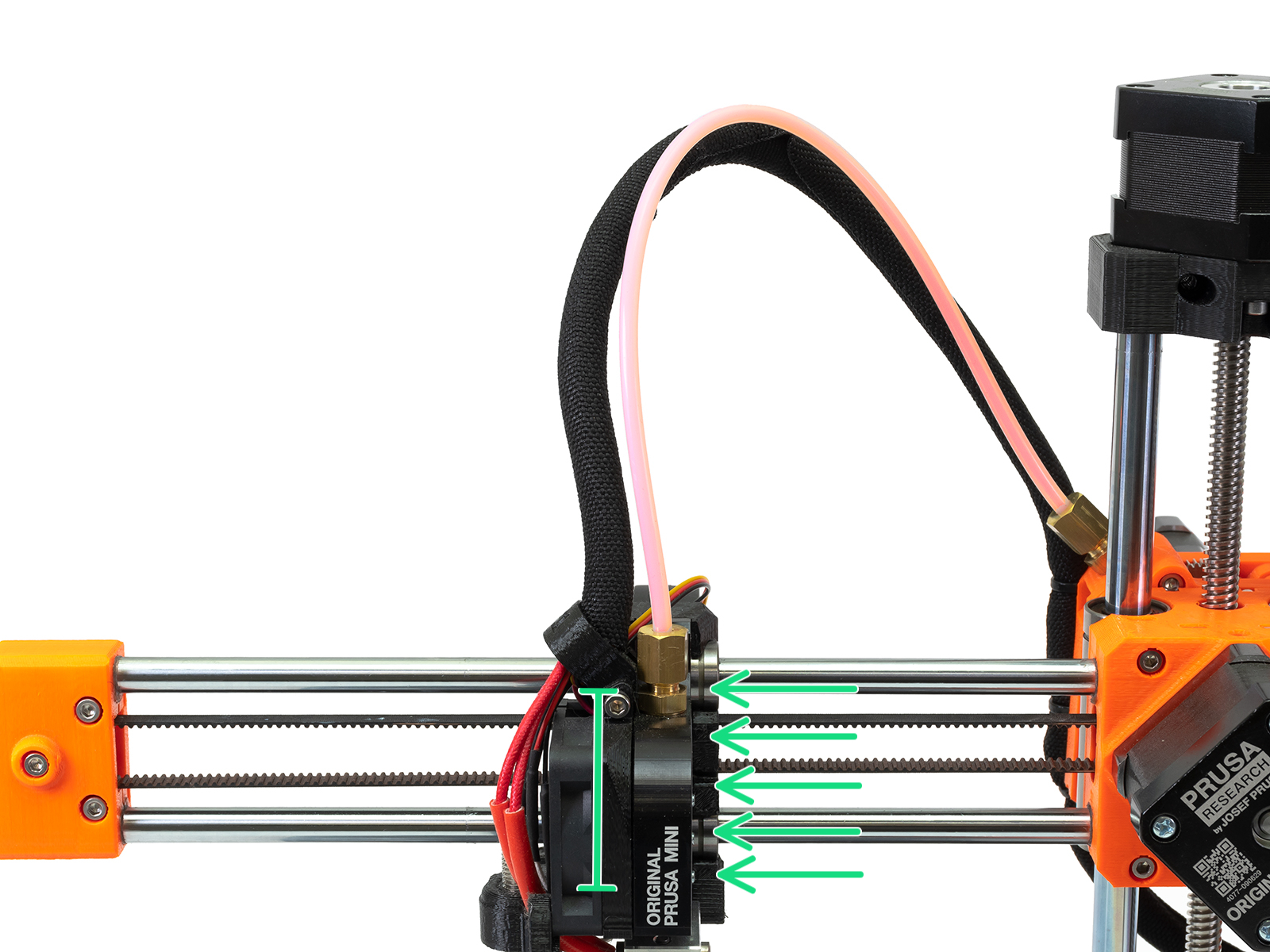

- Inside print head: The tip filament is not visible, stuck before the Bowden tube (green arrows).

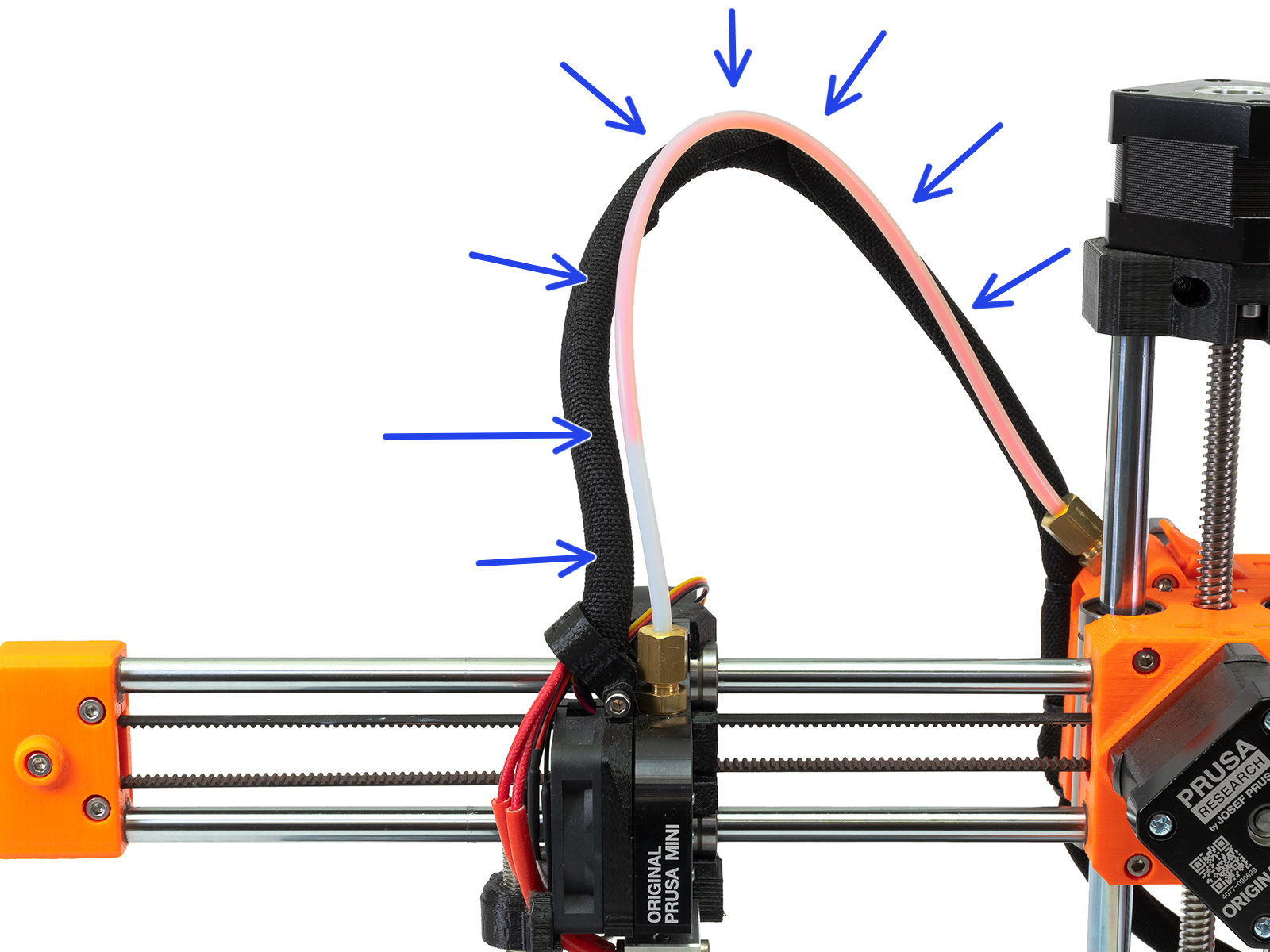

- Inside Bowden: The tip of the filament is visible and stuck in the Bowden PTFE tube (blue arrows).

|  |

| Inside print head - Stuck anywhere below the fitting | Inside Bowden - Stuck anywhere in the Bowden tube |

Stuck inside print head

- Make sure the nozzle is still heated to the temperature of the loaded filament. If the nozzle is cold, navigate to LCD menu -> Settings -> Temperatures -> Nozzles, and set the correct temperature.

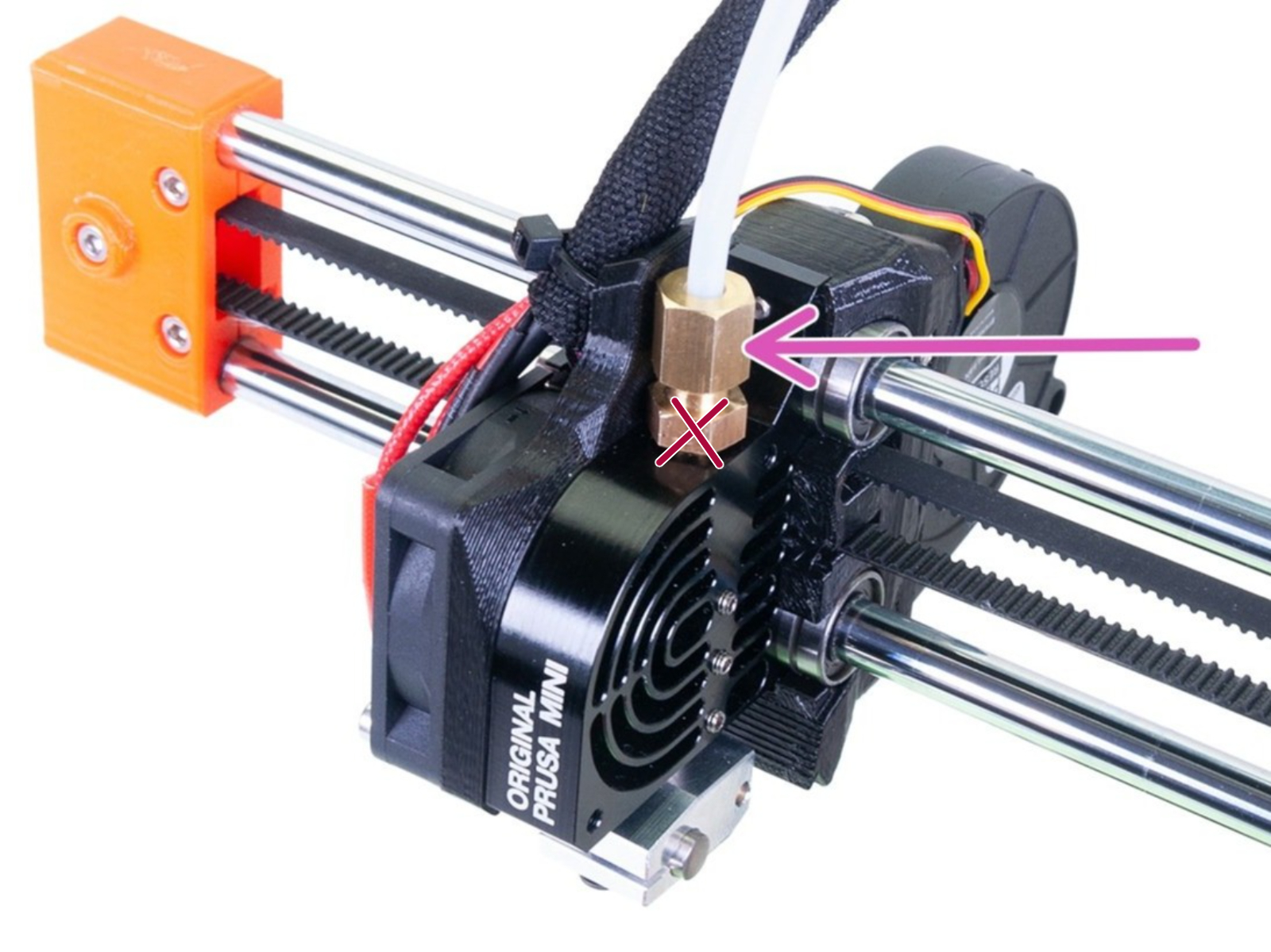

- Unscrew the large brass nut (purple arrow) securing the long PTFE tube, using pliers or a 10 mm spanner. The lower portion of the brass fitting should not be unscrewed nor removed!

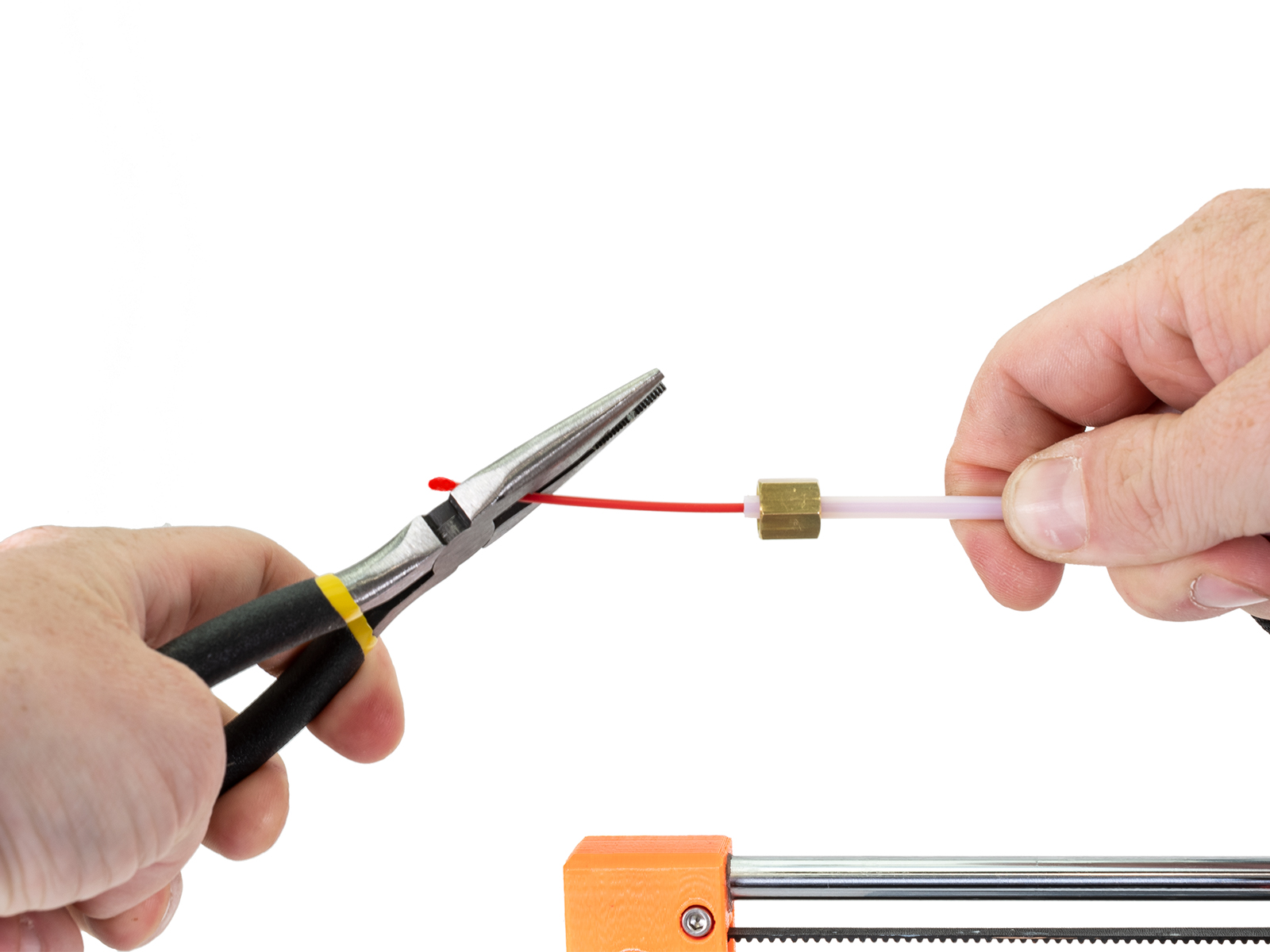

- Pull out the filament from the hotend PTFE tube. You may need to use pliers and there can be some resistance.

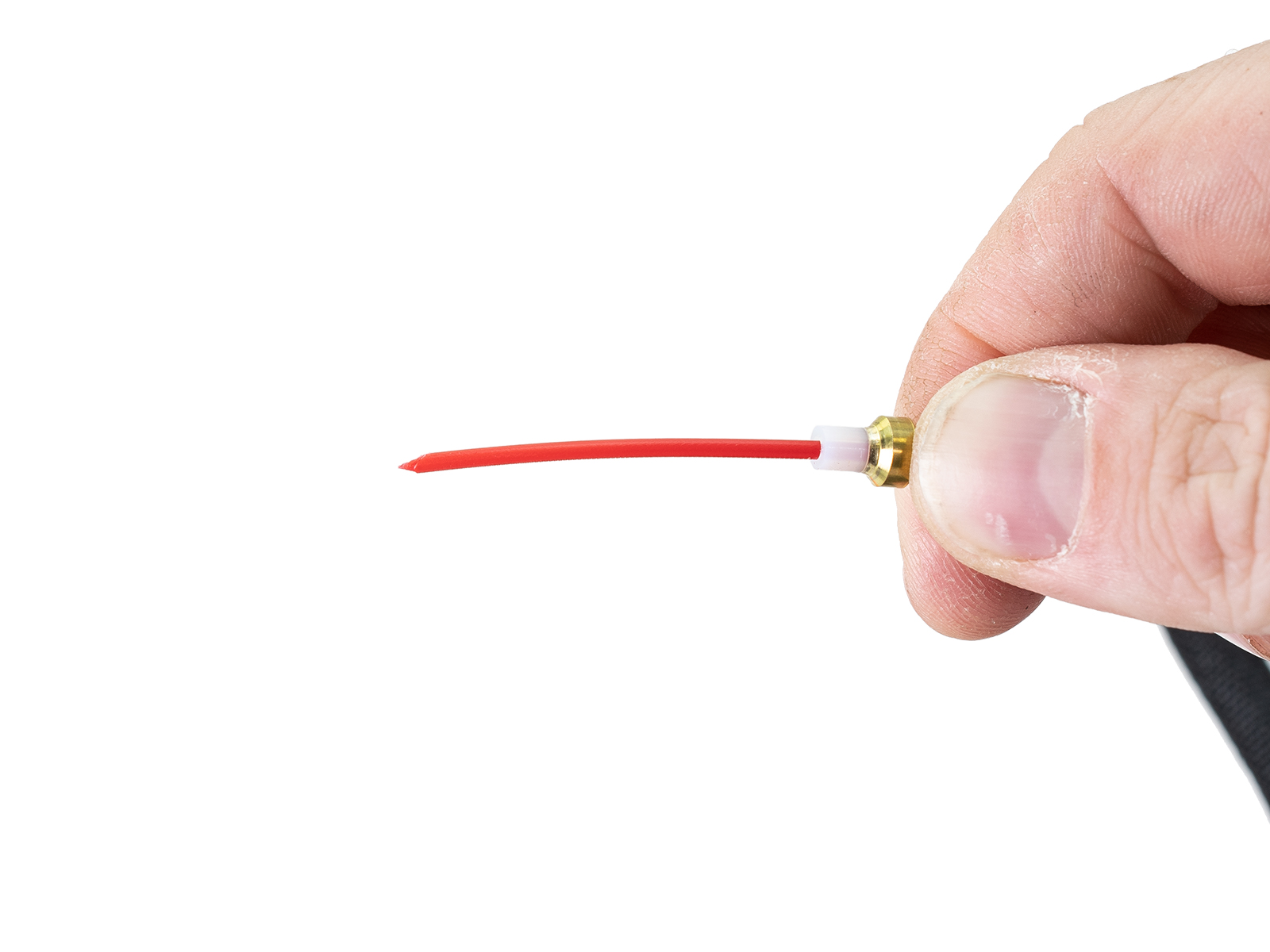

- Cut the irregularly shaped filament tip obstructing the unload, at a 45-degree angle.

|  |

- Repeat the unload filament function to completely unload the filament.

- Resecure the brass fitting and you should be ready to load a new filament.

Stuck inside Bowden

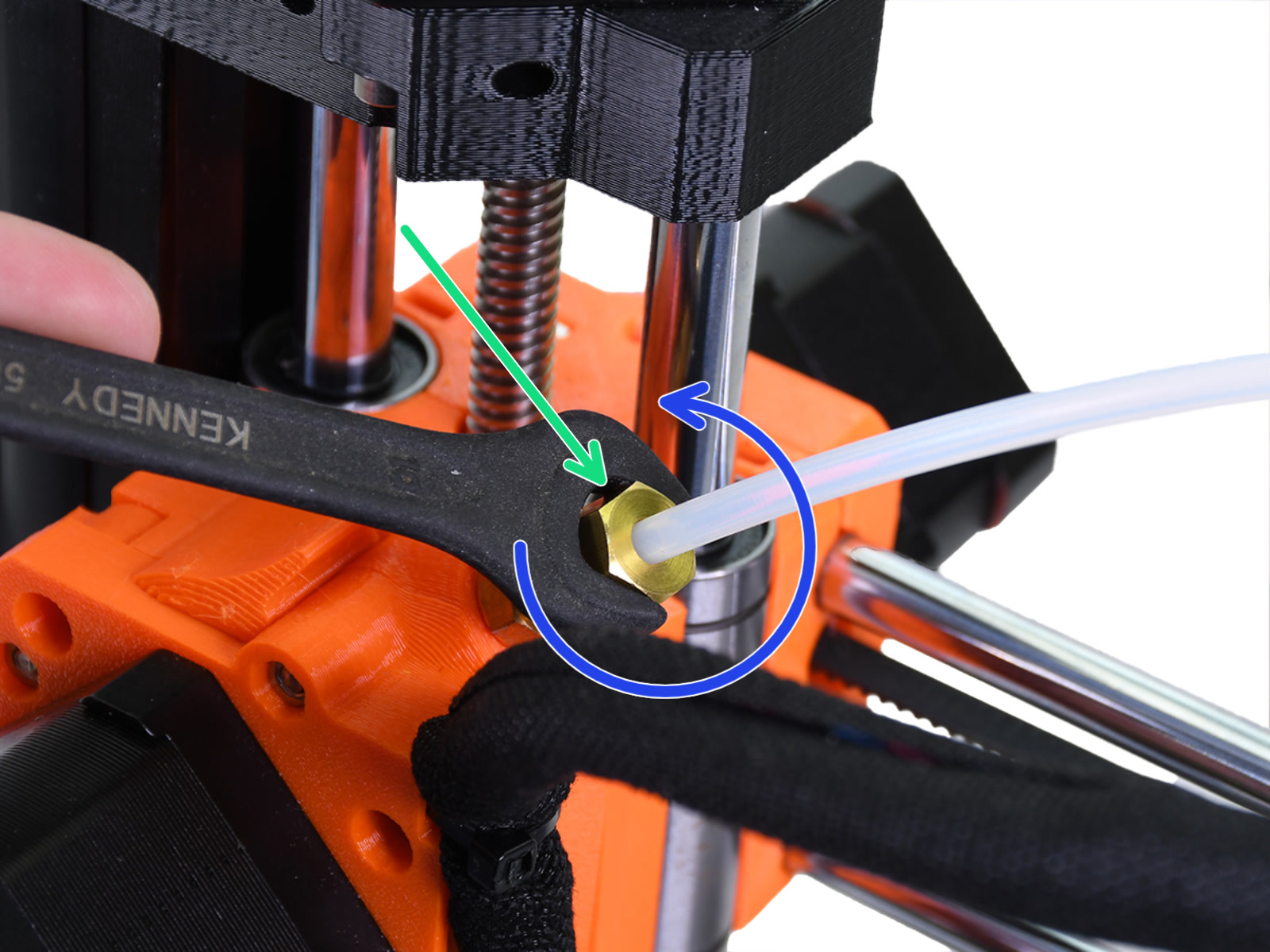

- Unscrew the large brass nuts (green and purple arrows) on both sides of the Bowden PTFE tube by using pliers or a 10 mm spanner (blue arrow). The lower portion of either brass fittings should not be unscrewed and removed!

|  |

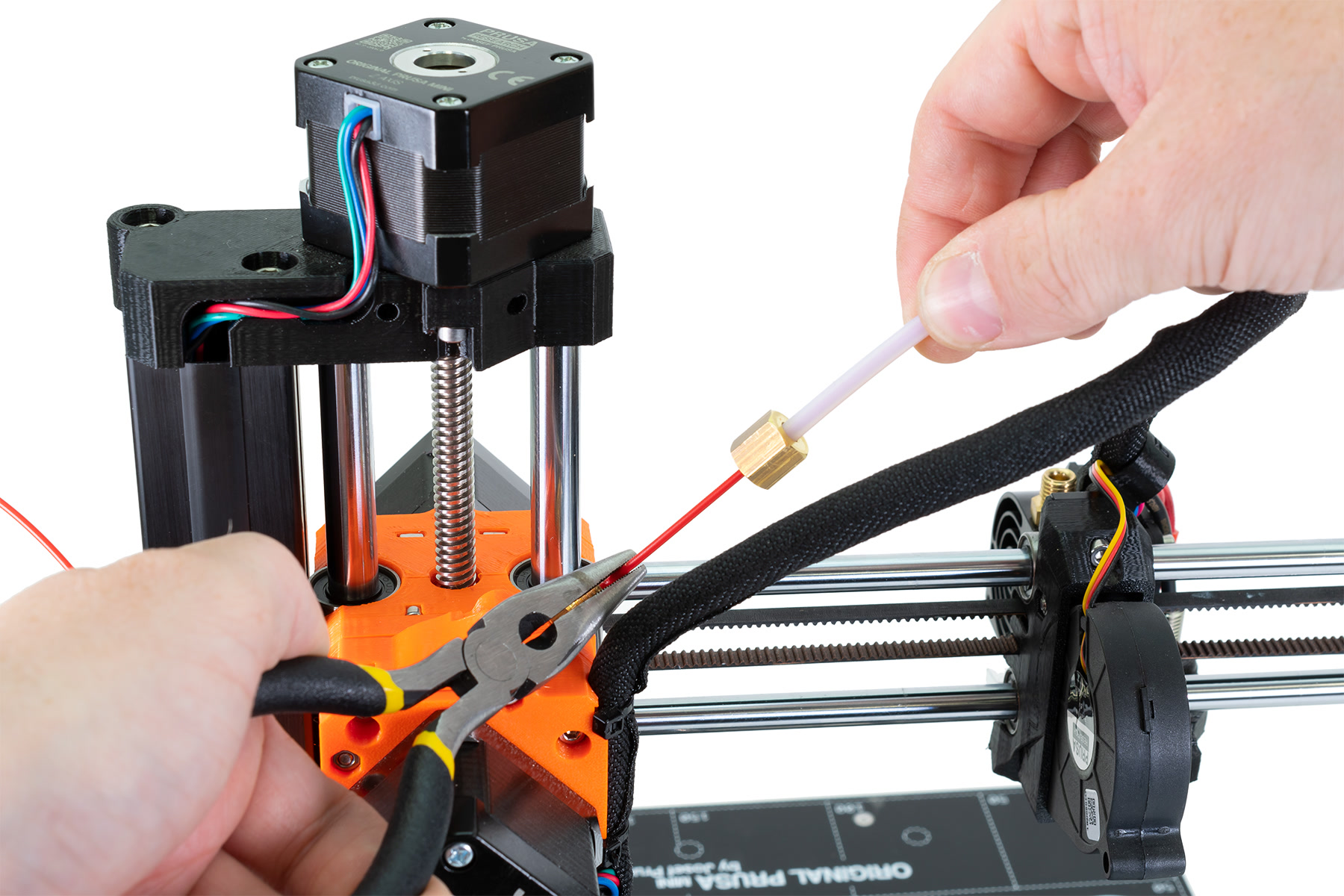

- On the extruder, secure the filament with a pair of pliers while pulling the PTFE tube off the filament using your other hand. You can expect an amount of resistance as the filament tip goes through the last bit of the PTFE tube.

- Cut the irregularly shaped filament tip obstructing the unload at a 45-degree angle.

- Repeat the unload filament function to completely unload the filament.

- Resecure both of the brass fittings and you should be ready to load a new filament.

After it is resolved

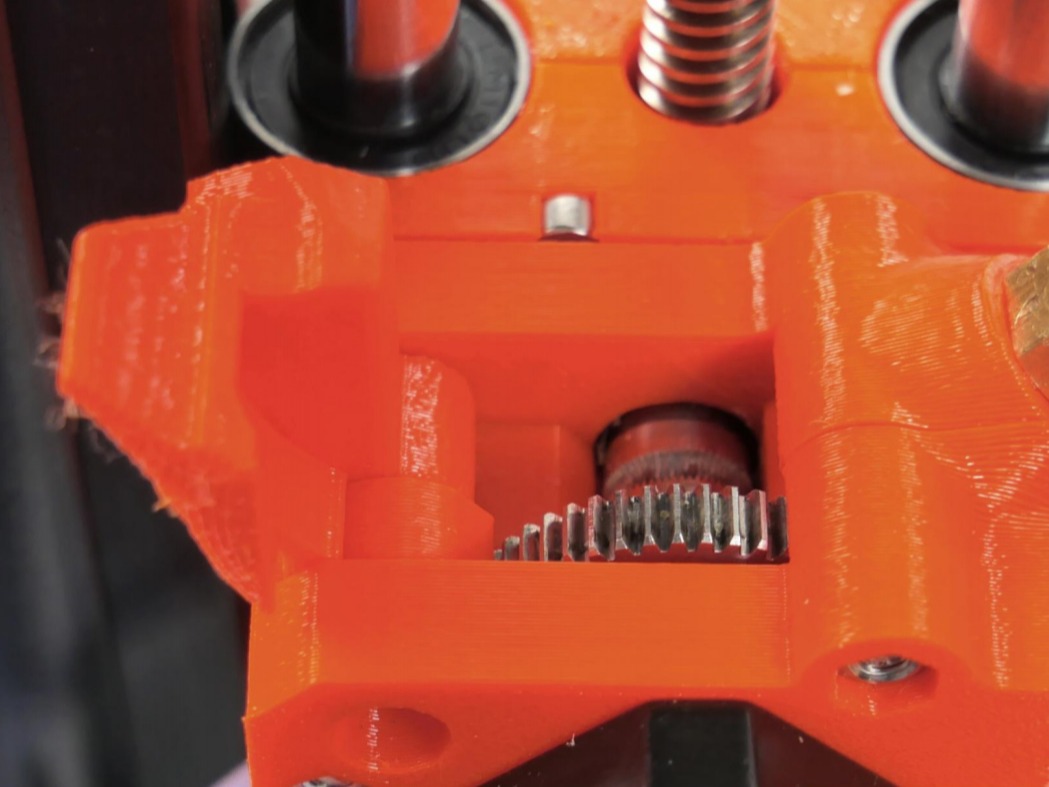

If you experience several failed unloads, the extruder's pulley gear (left picture) may have filament dust and debris in its teeth that need to be cleaned. Please see How to access and clean the extruder-pulley (MINI/MINI+) for detailed steps. Furthermore, make sure the idler screw is roughly flush with the plastic (right picture).

|  |

2 comments

If this happens regularly check the small ptfe tube inside the heat sink. The fillament that comes out of the hot end sits near the end of it to cool. Over time it can deform and enlarge the inner diameter of the tube in this spot. Which leaves a larger area for it to cool, resulting in the large blob. A new tube will get it to cool in the proper shape again.