If the filament is not loaded into the extruder, yet the printer is trying to pull the filament inside. It is usually a simple hardware problem, which we will fix in this article.

Ideal preparation checklist:

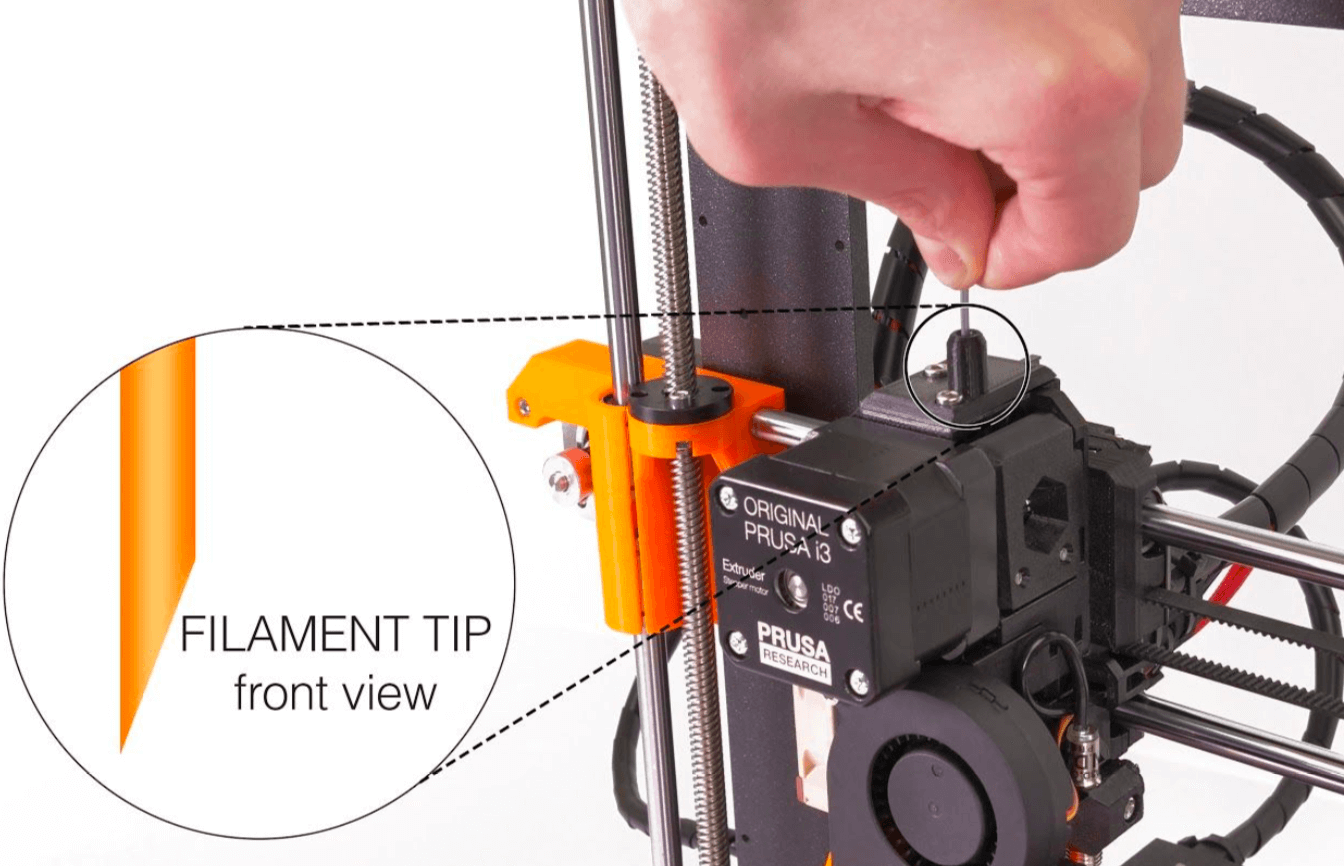

- Cut the tip of the filament at a 45-degree angle

- Filament goes straight around the pulley into the hotend PTFE tube - If the filament is bent slightly it may go around, especially flexible filaments are sometimes tricky to align perfectly!

- Make sure that there is as little deformation as possible of the filament which is being loaded in.

Make sure that you are using proper nozzle temperatures.

Mechanical problems:

- Loose pulley: ensure that the set screw of the extruder drive gear is secured against the flat side of the extruder motor shaft.

- Gummed up teeth: the extruder gear has teeth which bite into the filament, ensure that the teeth are clean and clear of any plastic. Clean the grooves in the gear if necessary.

- Extruder gear misalignment: the filament has to travel in a straight path, any sort of deviation will create friction and cause the extruder to either misdirect the filament or be unable to feed it properly. Visually check to see that the groove of the extruder gear passes directly in line with the top of the hotend PTFE tubing.

See the Re-aligning the Bondtech gears article. - Loose / Over-tightened Idler spring: The spring in the extruder is pressing the filament against the gears by pulling the idler gear or bearing. Make sure that the spring is not too loose, not too tight. See the Idler screw tension article for more info.

Would none of the above ease your problem. Please visit Clogged nozzle - MK2/MK3. There is a chance that you are dealing with a clogged nozzle, rather than Filament loading problems.

Was this article helpful?

This action is available only to registered users. Please log-in.

14 comments

Does anyone have an idea or had a similar experience?

In the end it was the PTFE tube going into the print head that was worn out. I cut off 2 mm, fixed.

I hope this can help someone in a similar situation.

This can happen either by the user - uncautious handling and some windings leave the spool sideways. Or it could be manufacturing error: Incorrectly wound spools. I even had this with one Prusament spool, actually the filament even changed direction on the spool!

Of course there is a limit to the force the extruder can pull, and so the nozzle can end up dry - in this case printing won't stop immediately. When later all limits are exceeded and printing does stop, your model cannot be rescued because the z axis is way too high now.

So always check proper winding of the spool, this is a SPOF.