3D scans and sculpted models often have a huge number of triangles, making them difficult to work with. These files can slow PrusaSlicer down, take a very long time to slice and even slow down FDM 3d printers, due to the huge number of short toolpaths generated.

You can reduce the number of triangles in a mesh using the Simplify mesh feature. Right-click the model and pick Simplify model from the context menu.

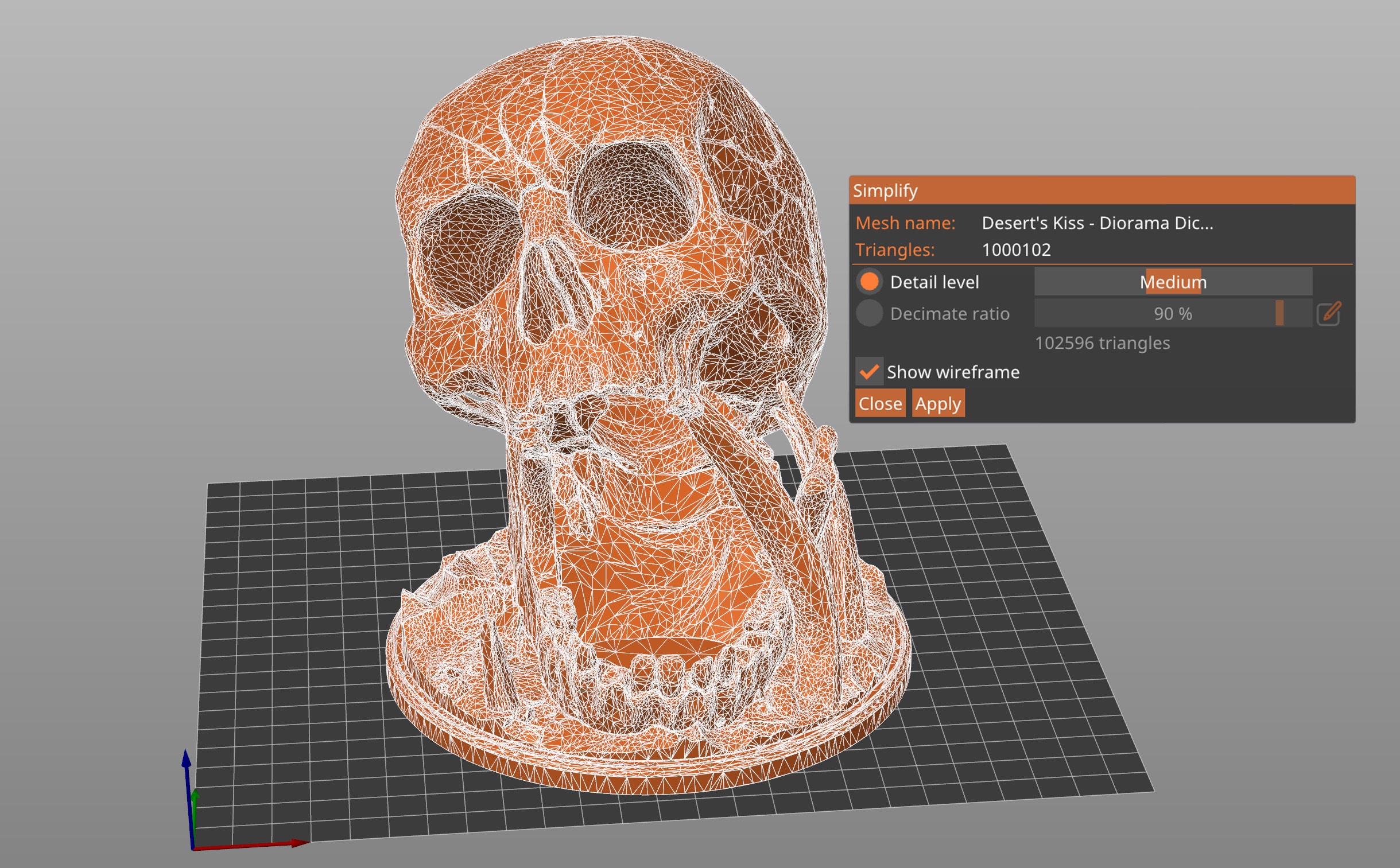

You can limit the simplification either by detail level or by the ratio of triangles to remove.

You can also enable the "Show wireframe" option to see white outlines of individual triangles.

A preview automatically starts being generated whenever you adjust the position of either slider. Once the simplification finishes, the simplified mesh will be displayed.

Clicking the Apply button uses the current settings for the simplification process and closes the dialog. You can revert this action with the Undo function (Ctrl+Z).

3 comments

So, I decided to figure this out with the help of the Internet, which just sent me to some crazy solutions that just made no sense. I did remember that the model came in with errors, which I fixed with Slicer, and it was a huge file. It came from Pritables.com and was likely from a 3D scan. Plus, I reduced its original size by 50%. What was happening is the model had these super-tiny tool paths that the printer just couldn't handle, leaving a small glob of filement at these points...likely worsened by the reduced scale, making those paths extremely tiny.So, I decided to use Simply Model command as I watched the traiangles greatly reduce with some setting changes, and the file reduced in size too. I printed it and the issue was 100% corrected, and the print head moved super smooth, as opposed to jerking all over the place, unnecessarily.

Lessone Learned: If you load a model into slicer and you get a File Size Warning, condsider Simplify Model. Otherwise your printer just works too hard and there is more chance for artifacts as it navigates those tiny tool paths.

So this page is useful but I could not give it a thumbs up or thumbs down because there are reasons to give it both. The Tumbs-Up / Thumbs Down, Like or Dislike systems of rating don't leave room for any other evaluative responses because they are binary. Maybe there are things to like and dislike about a page and other response options need to be available.

I thought I remebered a simplfy file feature in my slcier....well, Prusaslicer to the rescue! I kept the highest level of detail, lost absolutely nothing in the process and the slicer had the file down to a workable size in about 5 seconds!