The Original Prusa magnetic heatbed is designed to hold a removable, double-sided, flexible spring-steel sheet, specifically designed for easy removal of printed objects from the print surface.

Both sides of the smooth sheet are covered by a sticker made from PEI plastic. This is the same time-tested surface type that was used on the older MK2S printers. This sheet provides excellent adhesion with most filaments and geometries. So much in fact, that some filaments, like TPU and PETG, will adhere too much and can damage the sheet when removed. That is why we also have available the Textured sheet and the Satin sheet.

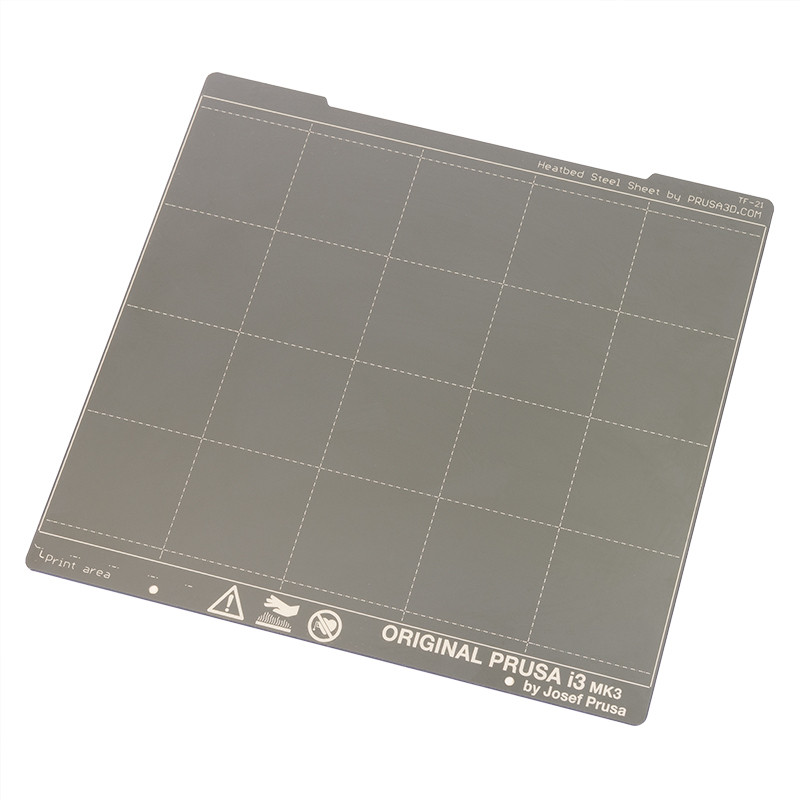

|  |

| Smooth sheet (color may differ from yours) | The underside of a printed object |

Print sheet color

The exact color depicted in the e-shop and our knowledge base may differ from yours. All sheets are checked and verified to be within tight specifications. These specifications consider the manufacturing method and the sheet's function (adhesion and durability used with certain material types), but not the cosmetic aspect of the sheet or pattern left on printed parts. We cannot guarantee the pattern left on your printed objects will match perfectly from sheet to sheet.

Main attributes

- Ideal for printing PLA, HIPS, ABS/ASA, composite materials (metal/wood).

- Prints with sharp corners or a small first-layer area are less likely to detach.

- Scratch-resistant. It can be used with a metal spatula; however, cosmetic scratches may appear.

- Double-sided! Both sides can be used interchangeably.

- Compatible with most types of filament.

- Thicker than the Textured and Satin sheets.

- Little to no surface preparation (other than cleaning).

- Clean with ~90% Isopropyl alcohol (IPA) or denatured alcohol.

- Can be cleaned with acetone, but do not overuse it (1-2 times per month).

- ABS juice can be applied to the sheet.

Considerations

- The live Z value needs to be readjusted if you switch sheet type, if you have a printer that uses the PINDA for bed leveling. See Steel sheet profiles.

- Some filaments, like PETG, ASA, ABS, and PC Blend, may need a protective separation layer, like gluestick, applied thinly before printing! See our extensive Material table.

- Keep the sheet clean! Any grease will greatly reduce adhesion.

Supported printers

Note that the sheets for the CORE One and the MK series sheets are interchangeable, just with different designs.

- CORE ONE, MK4/S, MK3.9/S, MK3.5/S, MK3/S/+, MK2.5/S (Also offered as Factory second)

- XL(Also offered as https://www.prusa3d.com/product/xl-smooth-pei-steel-sheet-factory-second/

- MINI/+ (Also offered as Factory second)

Maintenance

- Clean with ~90% IPA (isopropyl alcohol) or denatured alcohol when cold. Apply on an unscented paper towel and rub the sheet down. Do not use anything made for skin! It can contain oils that ruin adhesion!

- 1-2 times a month, it can be cleaned the same way with acetone if IPA cleaning is not sufficient.

- After extended use (1-2 years), the surface can smooth out further, which affects adhesion. Using high-grit sandpaper (600-1000), the PEI can be revived by light sanding, bringing fresh PEI to the surface. The sheet will have a very light texture after this treatment.

- The smooth PEI film on the steel sheet can be replaced in case of extensive damage.

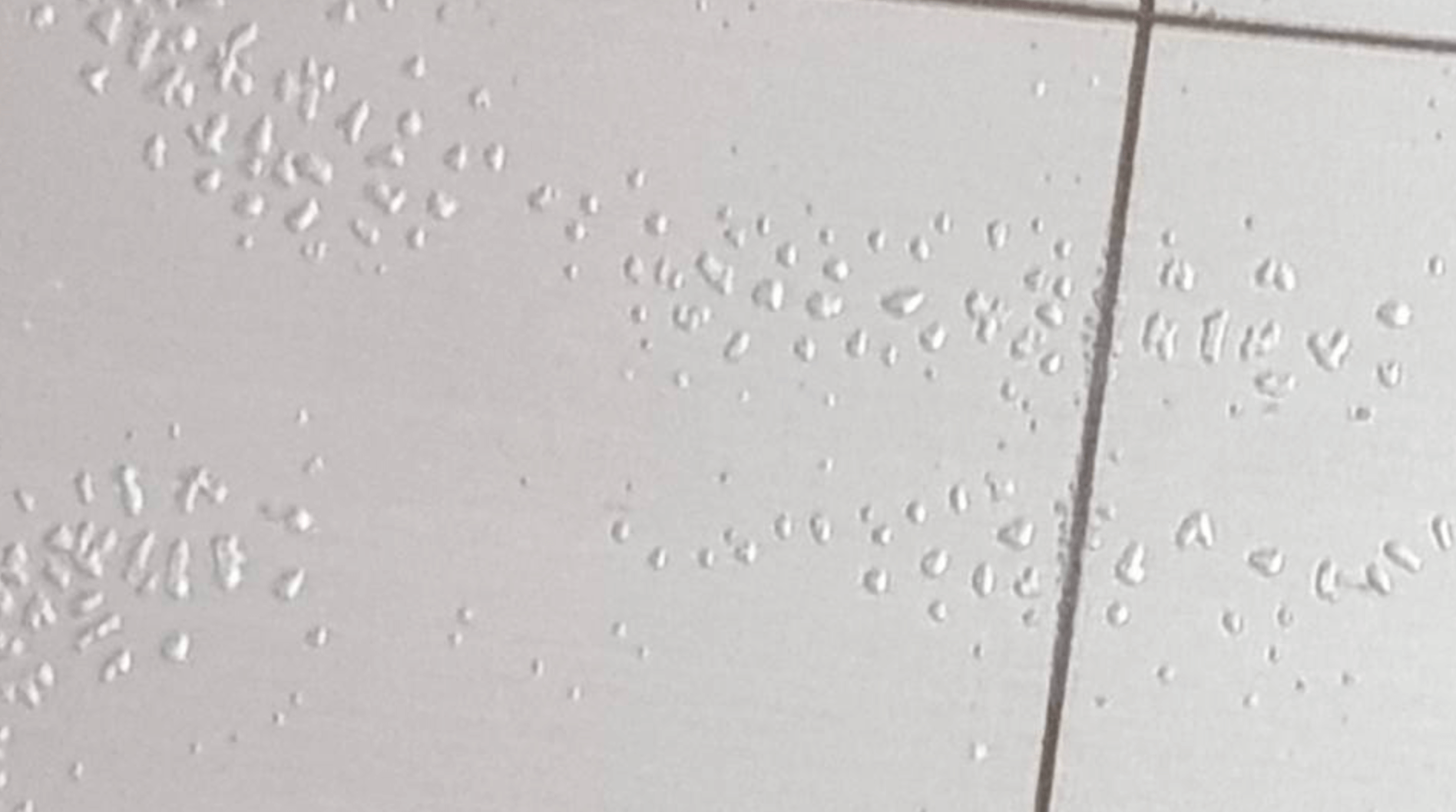

Bubbles underneath the PEI

Over time, you might see some small bubbles underneath the PEI. This is nothing serious. These bubbles usually do not affect print quality and will disappear after a few days or weeks. Here are 2 tips that will make these bubbles disappear faster:

- Swap the side of the steel sheet you were printing on. This will speed up the "recovery" of the PEI surface.

Bubbles appear around the spot where you print the most (center of the sheet), most often underneath the corners of your printed parts. - When slicing the models, vary your placement on the print surface. Don't use just one spot i.e., the center.

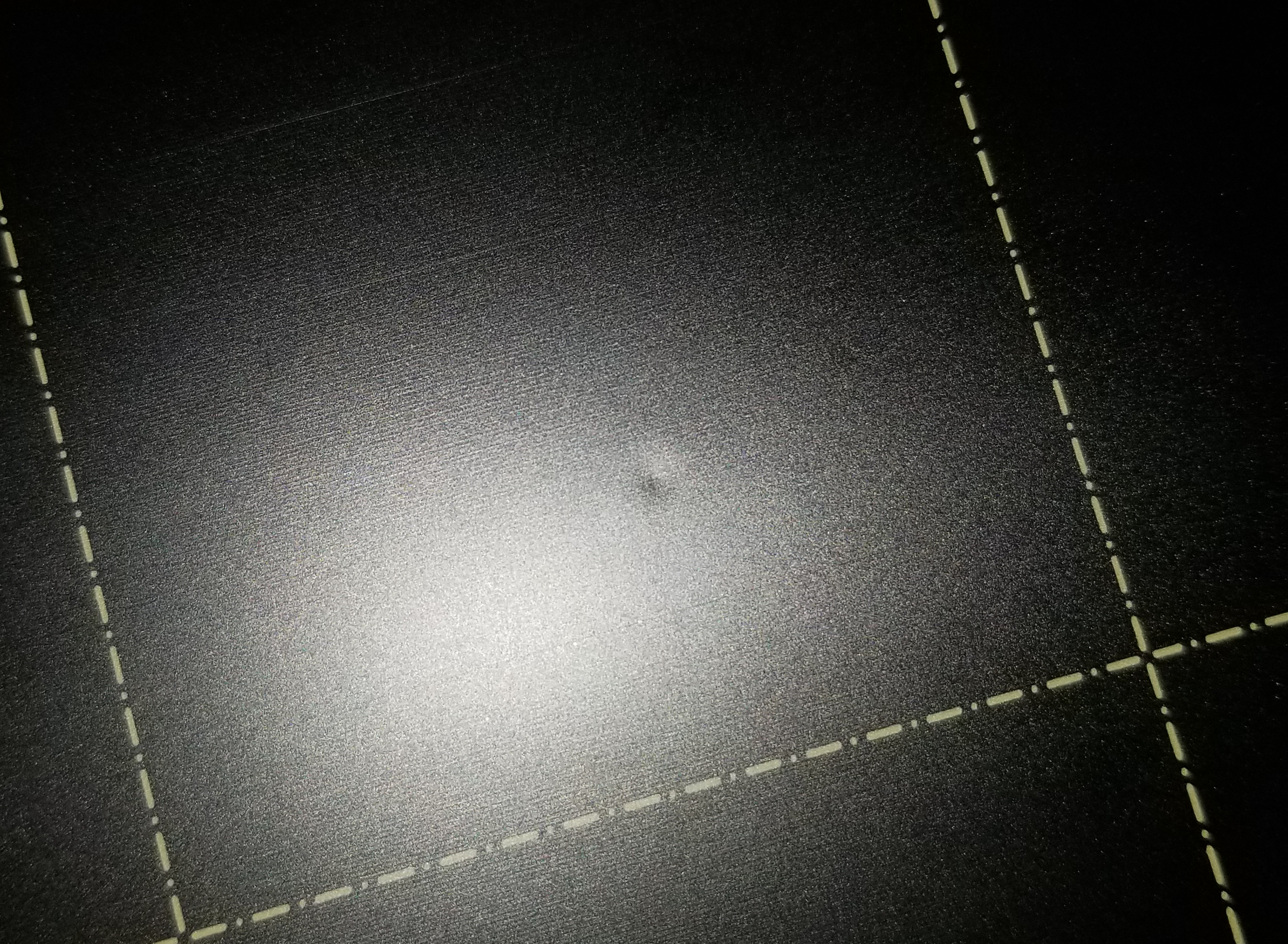

Dent in the PEI

Sometimes, there might be a small dimple or dent in the smooth PEI layer when you first unpack the steel sheet. Don't worry, just flip the sheet over and use the other side. Thanks to the heat of the heatbed, the dent will disappear by itself after some time (about 1-2 days of print time).

|  |

| Bubbles under the PEI sheet | Dents in PEI |

Filaments

We have done a lot of testing and compiled our results for you to use. To easily see how to prepare your sheet for any filament type, please see our Material table.

Prints don’t stick

If your print surface is perfectly clean and all grease has been removed by wiping it with a paper towel soaked in isopropyl alcohol 90% and if the first layer height is set up perfectly, yet your print still does not adhere reliably to the print surface, check out First layer issues.