⬢For this chapter, please prepare:

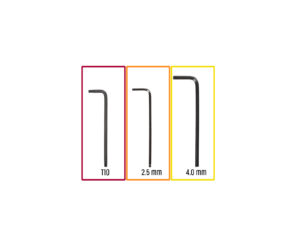

⬢T10 Torx key

You can also use a T10 screwdriver, which is included in the package

⬢2.5 mm Allen key

⬢4.0 mm Allen key

⬢Use a cardboard box as a heatbed protection during the setup. Use one of the Nextruder boxes that you received with your printer.