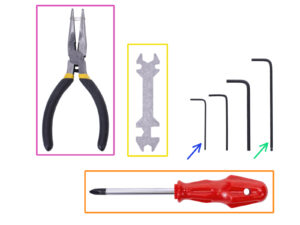

⬢Please prepare tools for this chapter:

⬢2.5mm Allen key for M3 screws

⬢2mm Allen key for nut alignment

⬢Needle-nose pliers for zip tie trimming

⬢Philips screw-driver for power cable assembly

⬢Universal wrench to tighten the QSM fittings

Older units may include a side wrench 8 mm.