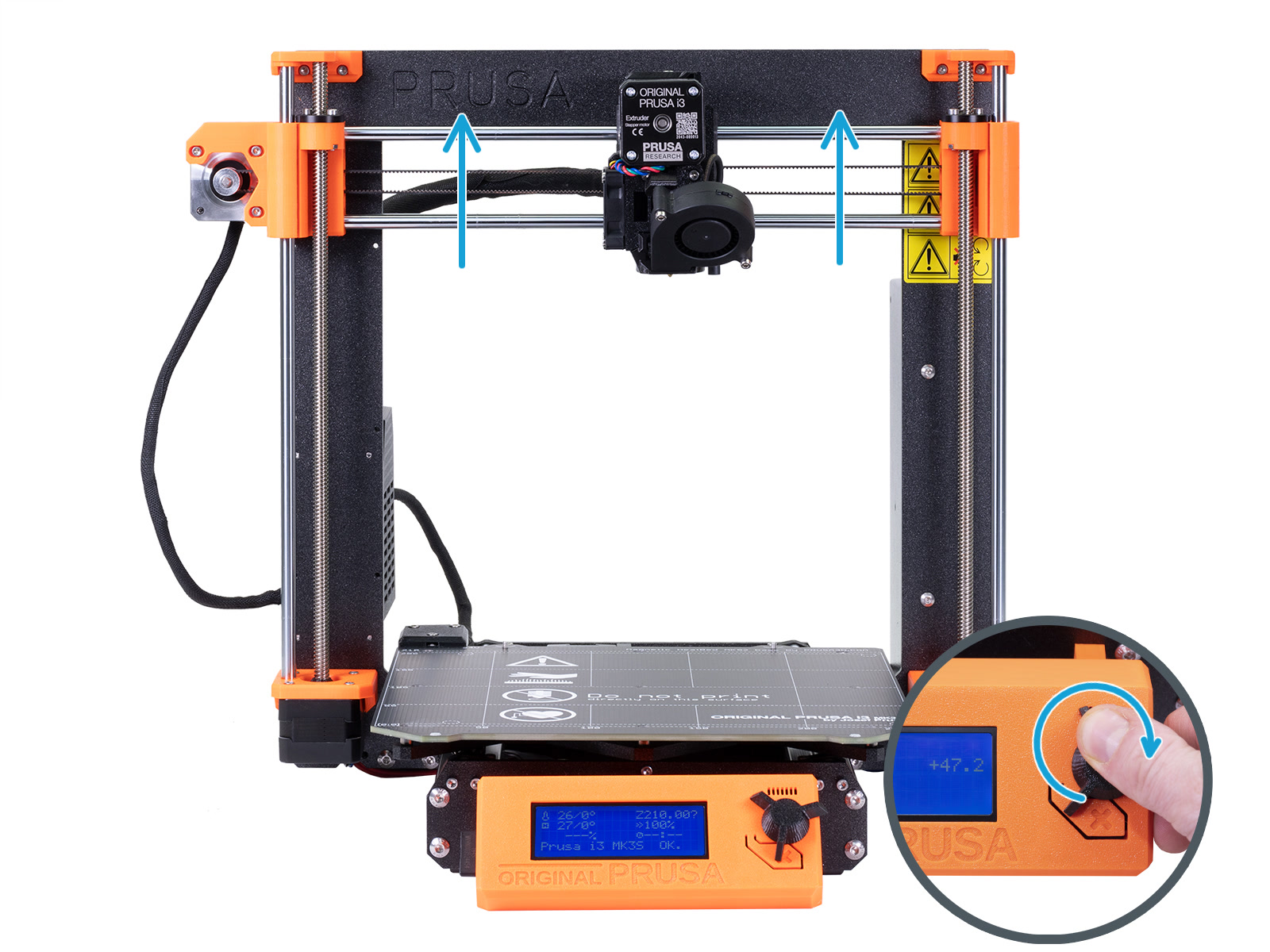

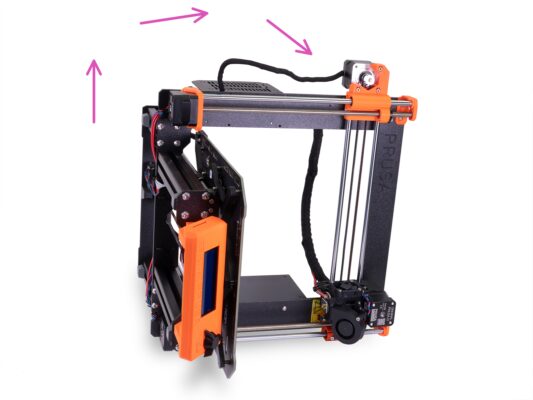

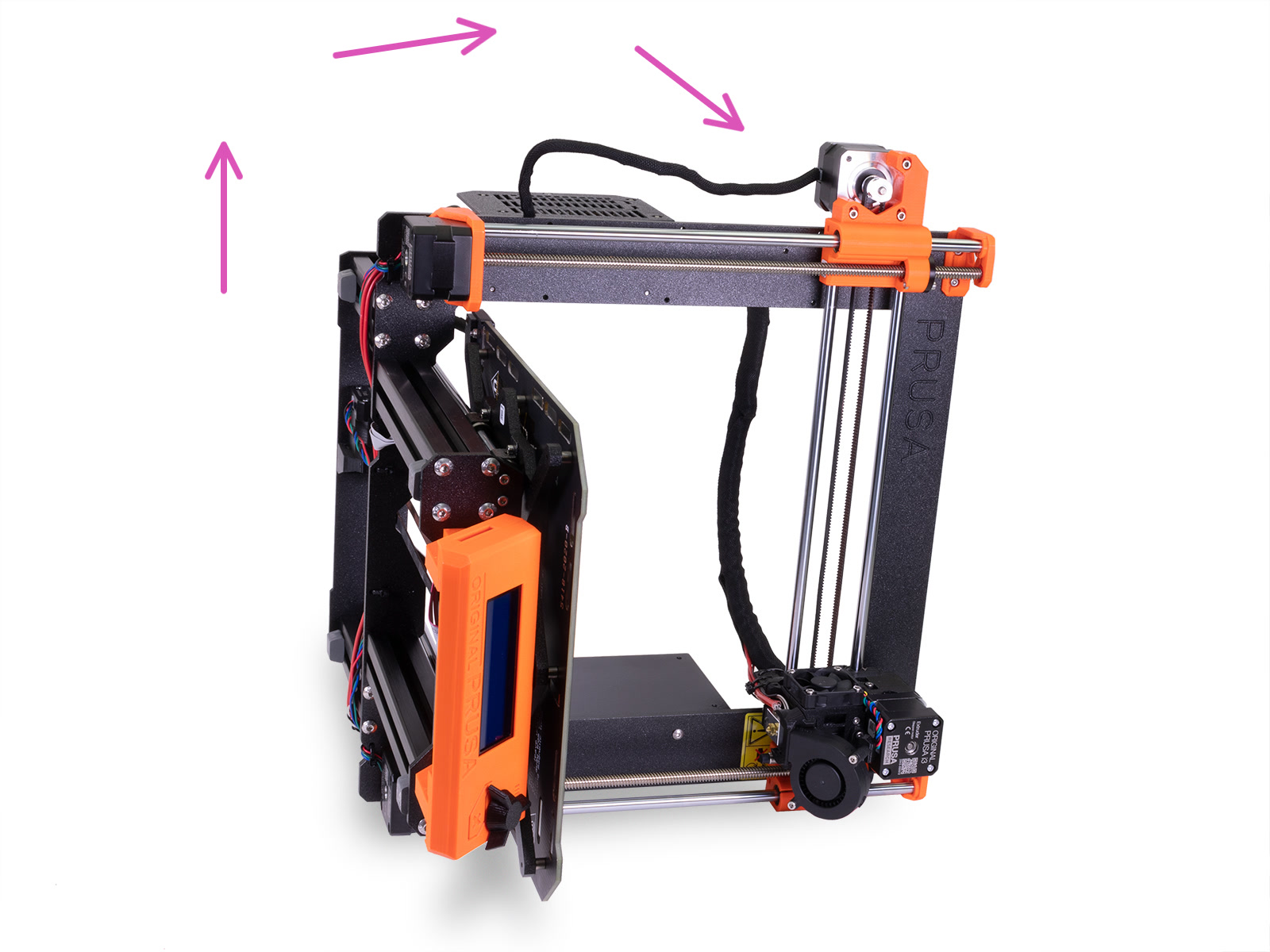

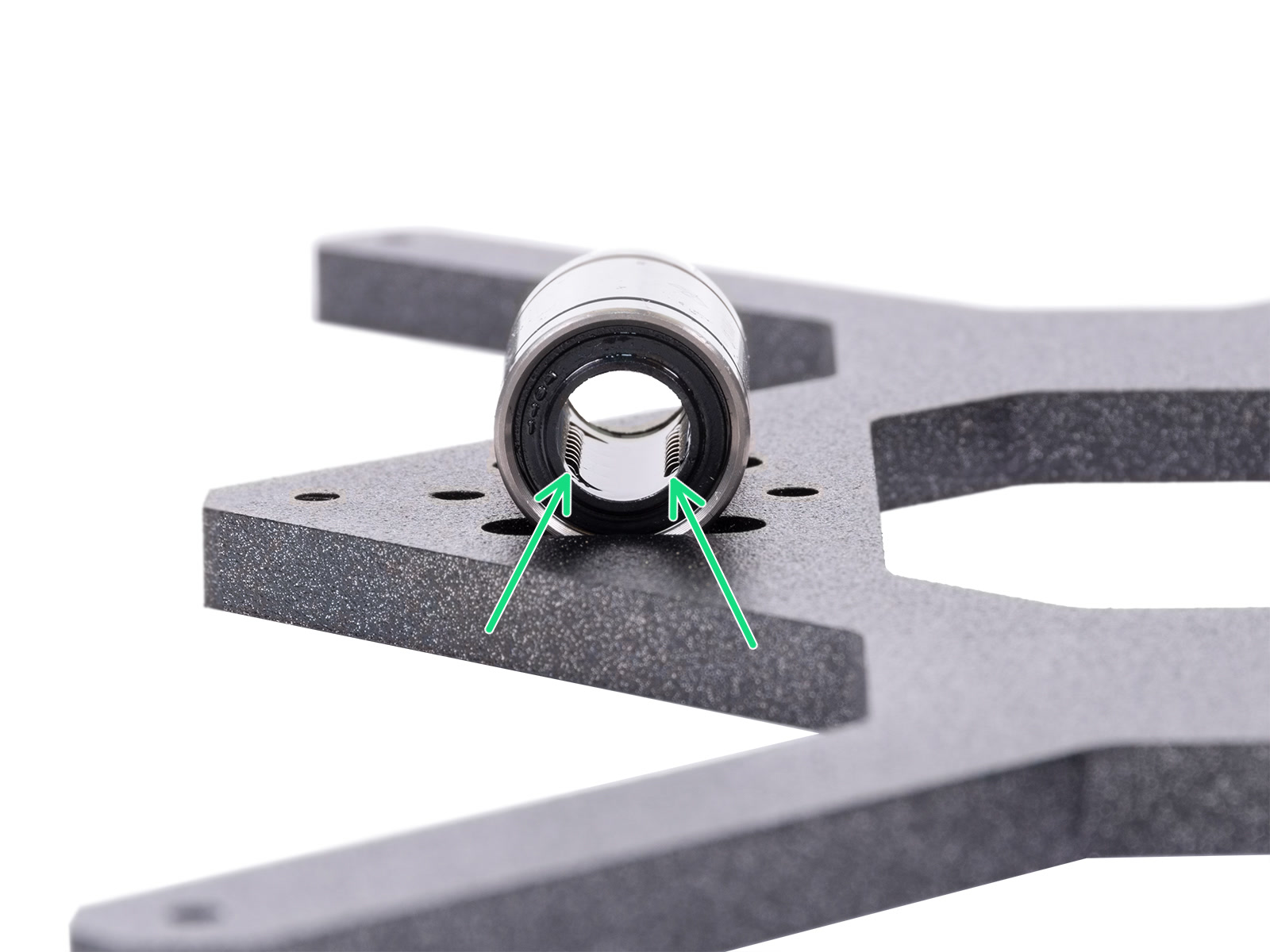

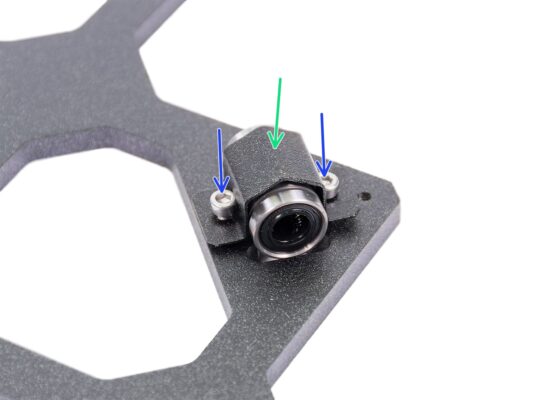

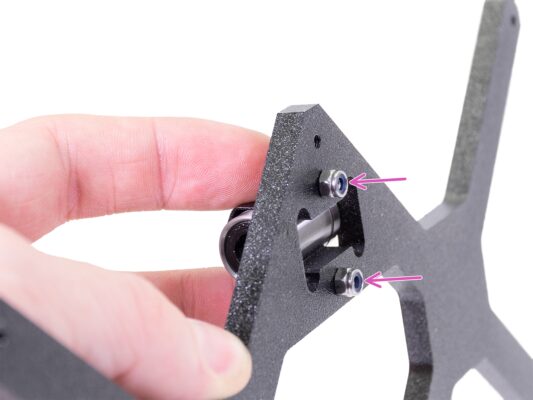

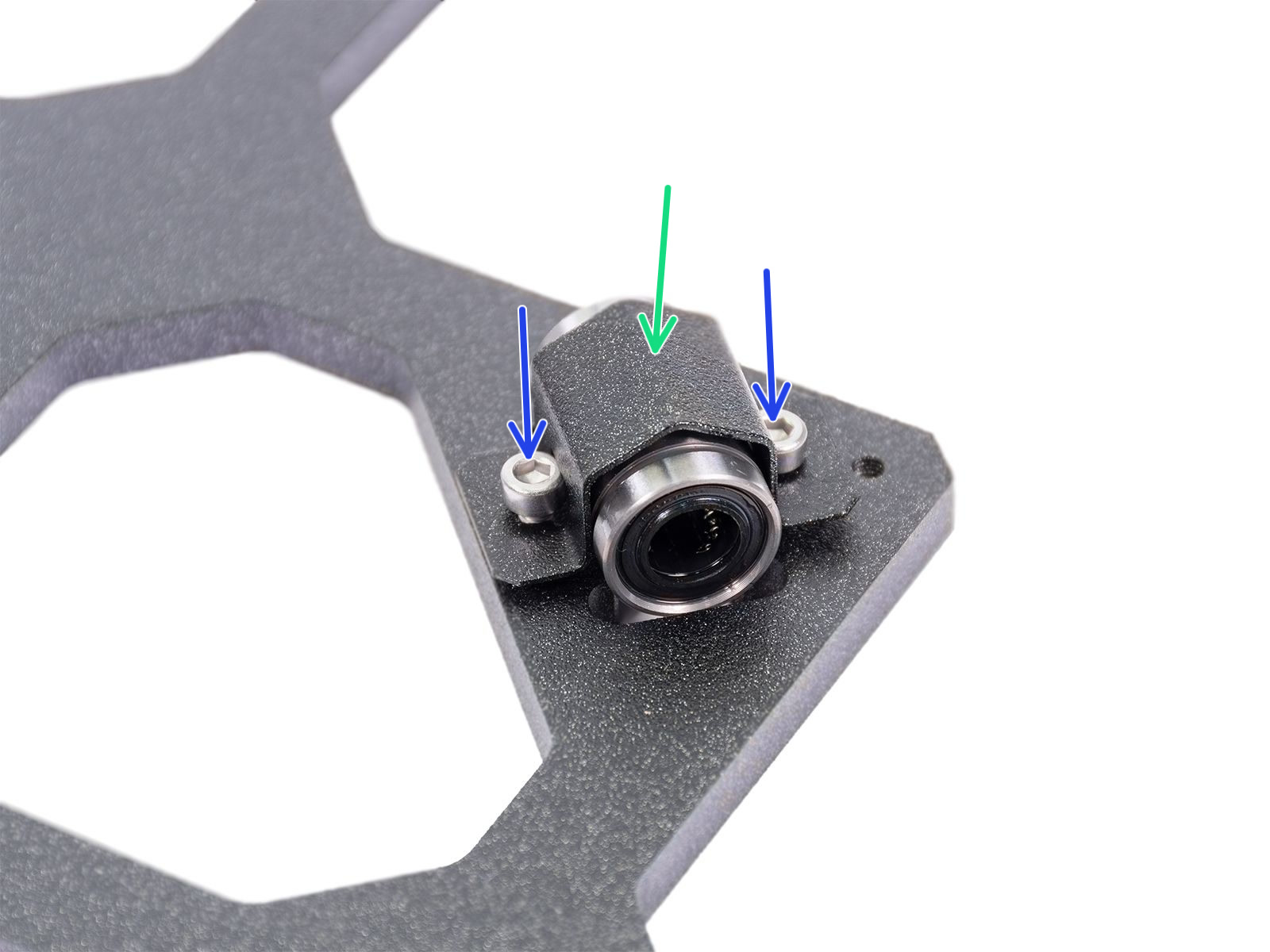

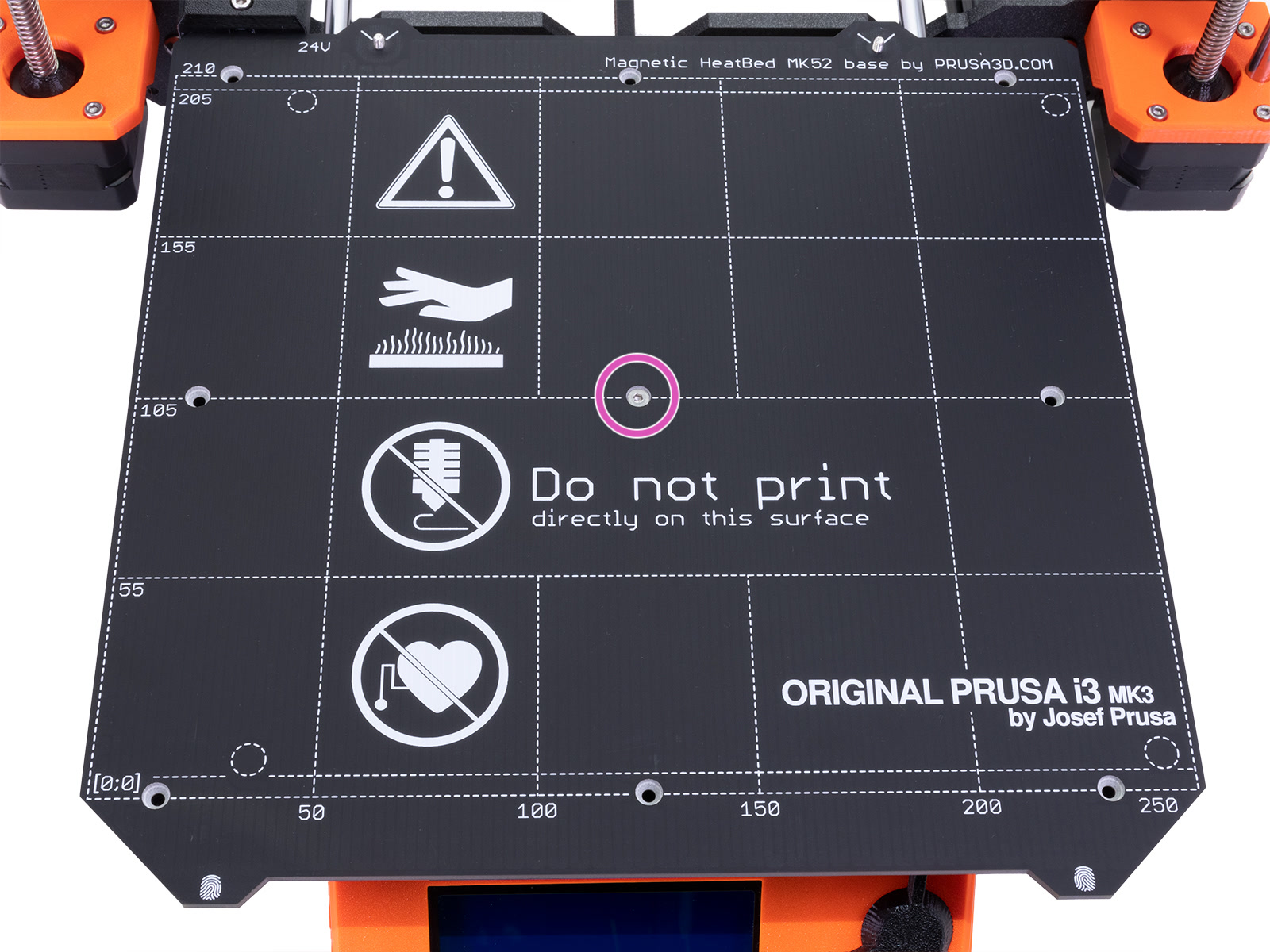

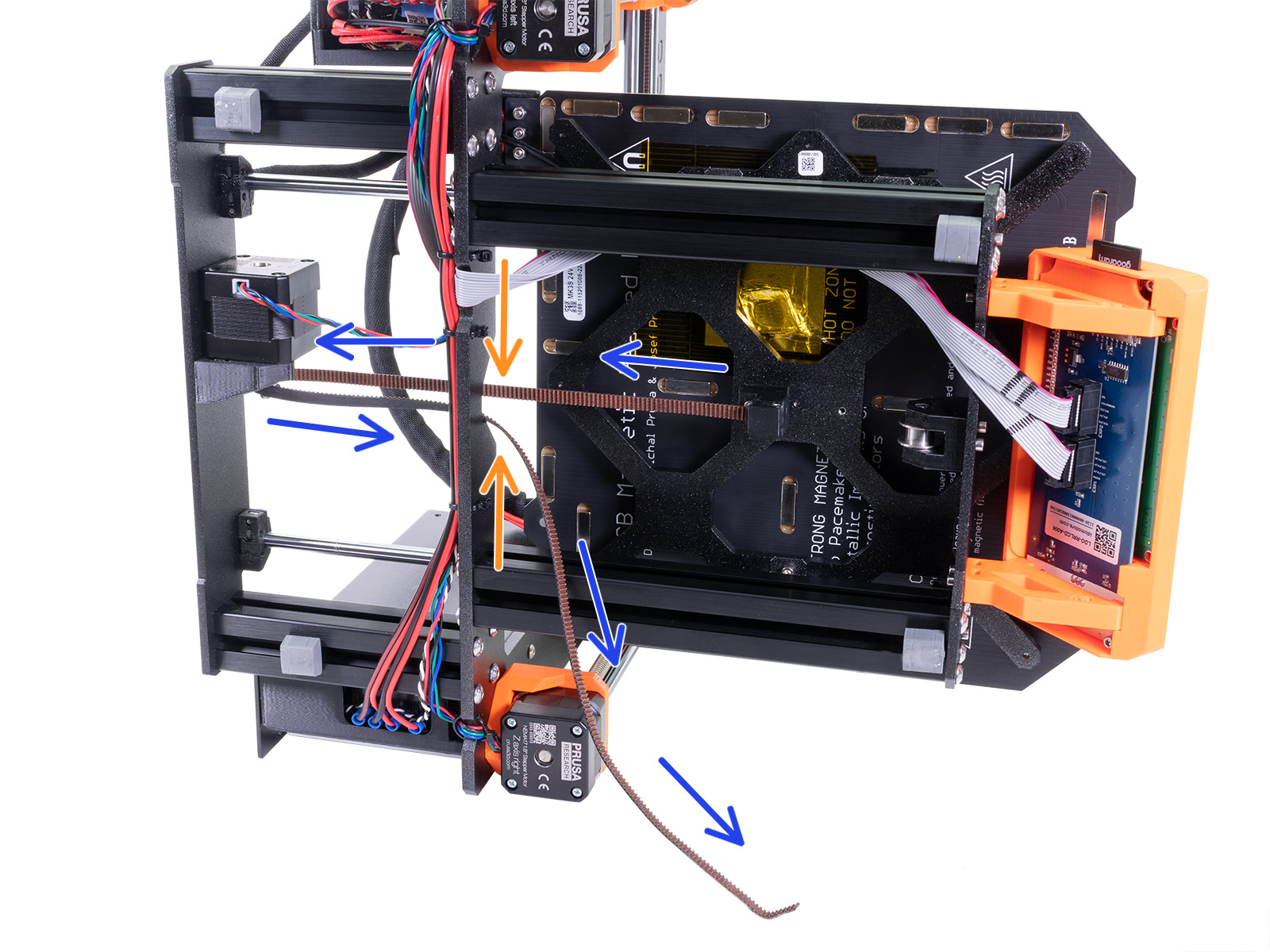

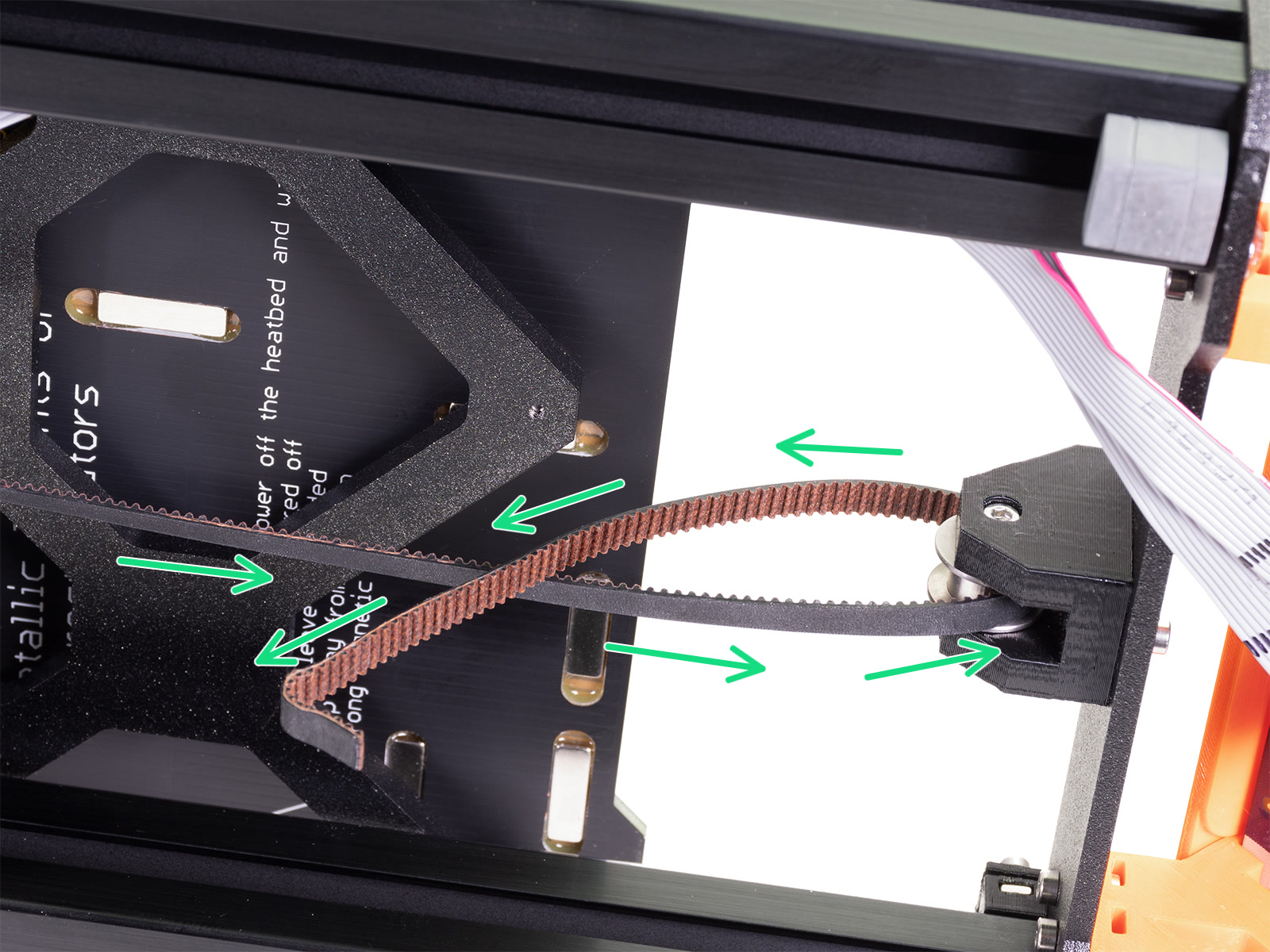

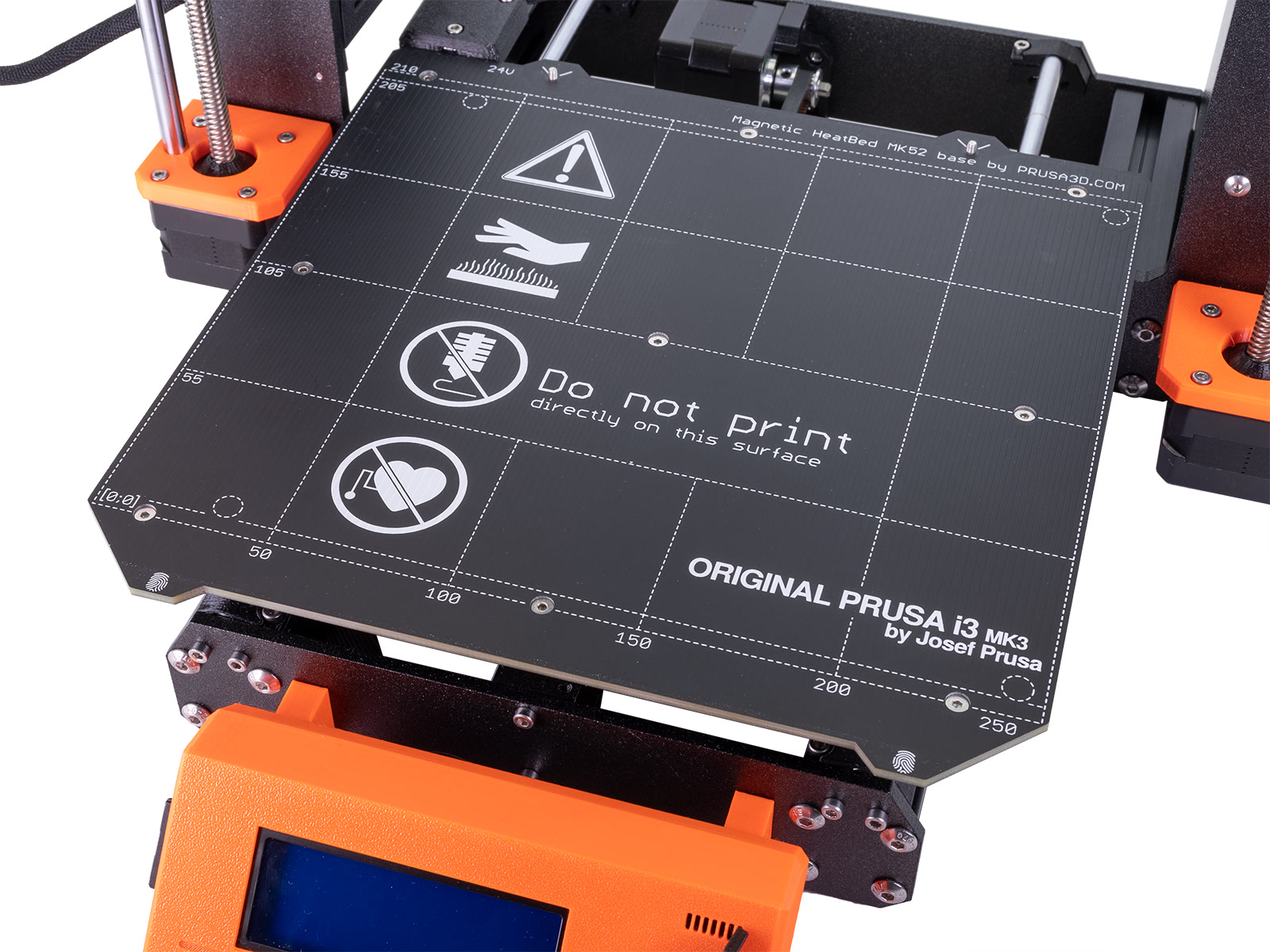

⬢This guide will take you through the replacement of the Y-axis bearings on the Original Prusa i3 MK3S+.

⬢All necessary parts are available in our eshop shop.prusa3d.com.

Note that you have to be logged in to have access to the spare parts section.

⬢For replacing X-axis bearings, please use this guide: How to replace bearings on the X-axis (MK3S+)