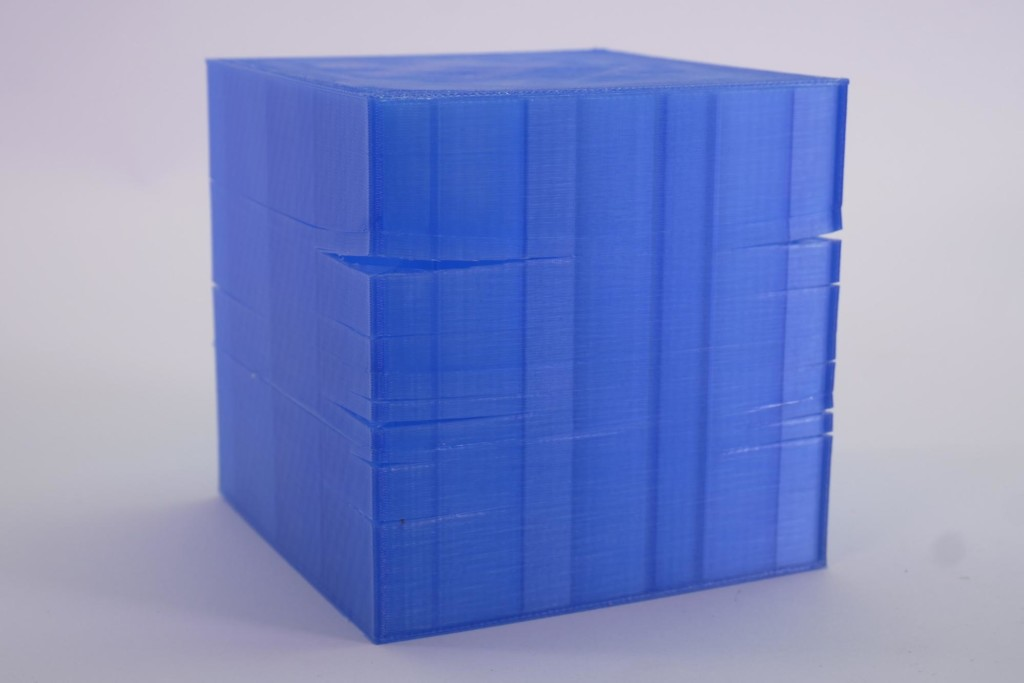

This refers to the de-lamination of the printed layers. It is mostly caused by an incorrect preset/(custom)profile with wrong temperatures and/or too much cooling from either the print fan or the sorrounding environment.

It’s not difficult to tell the difference between cracking and missing layers. Best way to identify cracked layers are the clean cuts that show a bit of an upward bend or warp.

Layer separation occurs when the object cracks due to forces exerted on the print when layers cool down at different rates. Warping forces exceed the layer adhesion strength and the layers separate.

How to prevent Layer separation and Splitting

ABS is highly susceptible to layer separation when there’s any sort of cold air blowing on the print before it has cooled down fully. We suggest turning fans OFF for ABS prints completely.

Please remember that you may probably not be able to print objects covering the whole print area using ABS, so it is better to replace ABS with PETG filament. PETG has similar advantages ABS, but it’s much better for printing large objects and it does not have the same tendency to crack/de-laminate. ASA is also a great alternative but is still more dependent on a stable environment when printing than PETG. You can check the material guides for choosing the best material for your print.

PLA may suffer from cracking and layer separation problems if you’re printing with insufficient temperature. Depending on the brand, PLA is printed at a range between 195-220. If you are having issues, try increasing the printing temperature in 5°C increments, until you get a good layer adhesion.

Flow-rate / extrusion multiplier

Increase your printer’s flow rate (in PrusaSlicer called extrusion multiplier). More material extruded will create a stronger bond between layers. increase on 5% increments. For more info please see Extrusion multiplier calibration.

2 comments