- English

- Italiano

- Deutsch

- Polski

- Français

- Home

- O vaší tiskárně

- Vlastnosti tiskárny

- PP steel sheet

PP steel sheet

- Popis tiskárny

- Vlastnosti tiskárny

- Akcelerometr (MK4/S, MK3.9/S)

- Nastavení jasu (SL1)

- Buddy firmware-specific G-code commands

- Zrušit tisk objektu (MK4, MK3.9, XL, MINI/+)

- Crash detekce

- Výpis chyb

- Tvorba kalibračního objektu resinu (SL1/SL1S)

- Výpis paměti (MK3/S/+ a MK2.5/S)

- Experimentální menu (MK3/S/+)

- Experimentální nastavení (MK4/S, MK3.9, MK3.5, XL, MINI/+)

- Senzor filamentu (MK4/S, MK3.9/S, XL)

- Senzor filamentu MK3 (neplatí pro verzi S)

- Flashing custom firmware (MK4/S, MK3.9/S, MK3.5/S)

- Pružné ocelové pláty (rozcestník)

- GPIO Module

- Tisková hlava s vysokým průtokem (HT90)

- High temperature print head (HT90)

- HW nastavení (MINI/MINI+)

- HW nastavení (MK2.5/S & MK3/S/+)

- Internetové připojení (SL1/SL1S)

- Senzor filamentu (MK2.5S, MK3S/+, MK3.5/S)

- Detekce IR senzoru filamentu (MK3S)

- Úprava jasu LCD displeje (MK3S)

- Úprava kontrastu LCD displeje (i3)

- Loadcell (MK4/S, MK3.9, XL)

- Struktura menu (SL1/SL1S)

- MMU3 tryska Prusa vs. tryska CHT

- Náhled modelu

- Network Connection (MK4S, MK3.9S)

- Silikonový návlek Nextruderu (XL, MK4, MK3.9)

- NFC antenna

- Hlučný senzor filamentu (MINI)

- Tisk jedním kliknutím

- Nalití resinu a zahájení tisku

- Power panic (ochrana před výpadkem proudu)

- Tiskové režimy

- PP steel sheet

- Main attributes

- Considerations

- Maintenance

- Filaments

- Prints don’t stick

- Notes

- Tiskový profil (SL1/SL1S)

- Statistika tisku

- Statistiky a informace o tiskárně (SL1/SL1S)

- Pronterface a USB kabel

- G-cody specifické pro Prusa Firmware

- Prusa Pro Filament Drybox

- Kalibrace pryskyřice (SL1/SL1S)

- Čištění vaničky na resin (SL1/SL1S)

- Saténový ocelový tiskový plát

- Uspořádání souborů na SD kartě

- Hladký ocelový tiskový plát

- Zvuk (MINI/MINI+)

- Speciální PA Nylon tiskový plát

- SpoolJoin (MMU2S)

- Profily vyhřívaných podložek

- Detekce zaseklého filamentu #26101 (MK4S) #13101 (MK4) #21101 (MK3.9) #17108 (XL)

- Menu Podpora (MK3/S/+)

- Nastavení podpěr pro XL

- Texturovaný ocelový tiskový plát

- Kalibrace termálního modelu

- Tools Mapping (XL)

- Tools Mapping and Filament Mapping (XL, MMU3)

- Oznámení na horní liště (SL1/SL1S)

- Dotyková obrazovka (MK4, MK3.9, MK3.5, XL)

- Nabídka „Ladit“

- Vodou rozpustné materiály (PVA/BVOH)

- Obecné informace

The Original Prusa magnetic heatbed is designed to hold a removable double-sided flexible spring-steel sheet, designed specifically for easy removal of printed objects from the print surface.

|  |

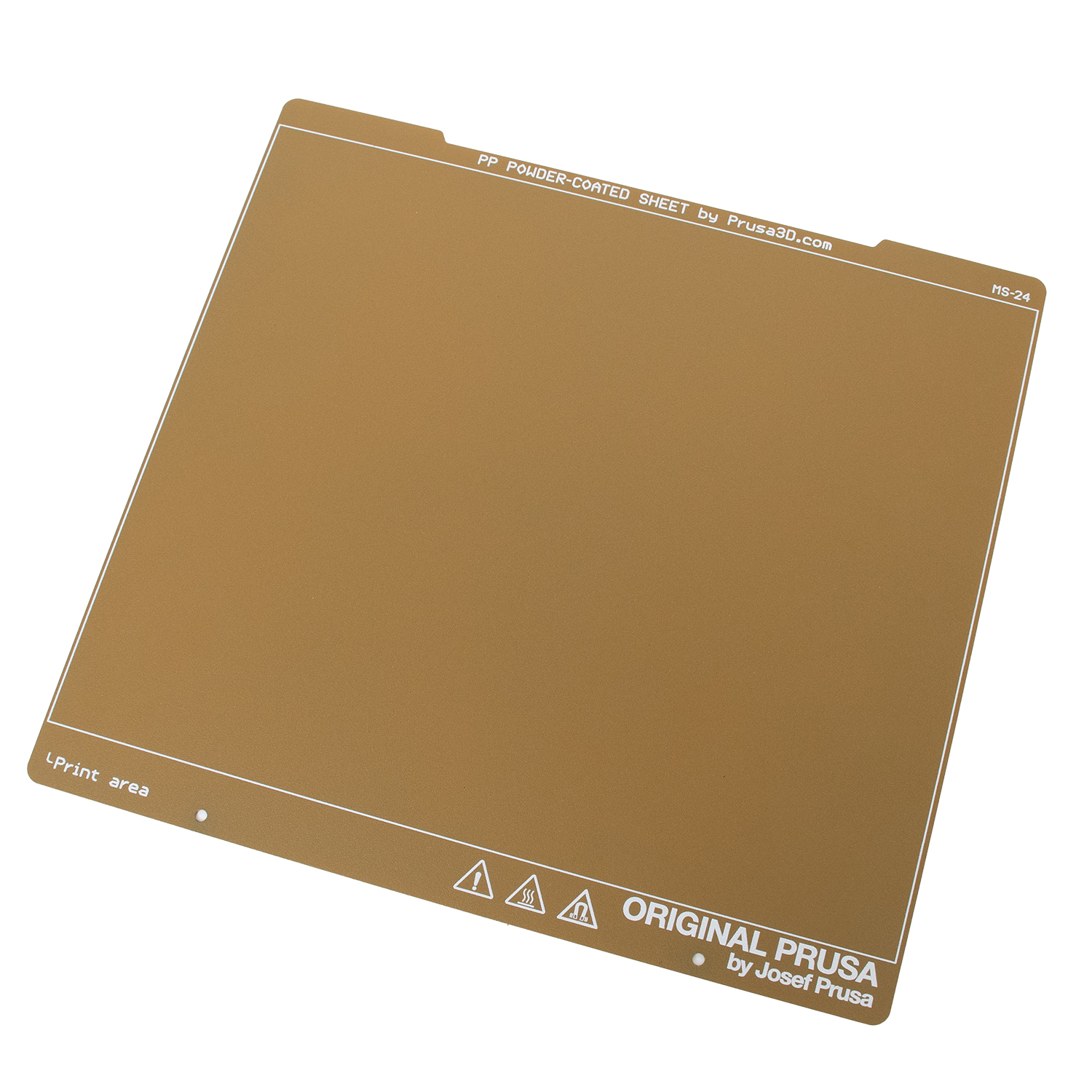

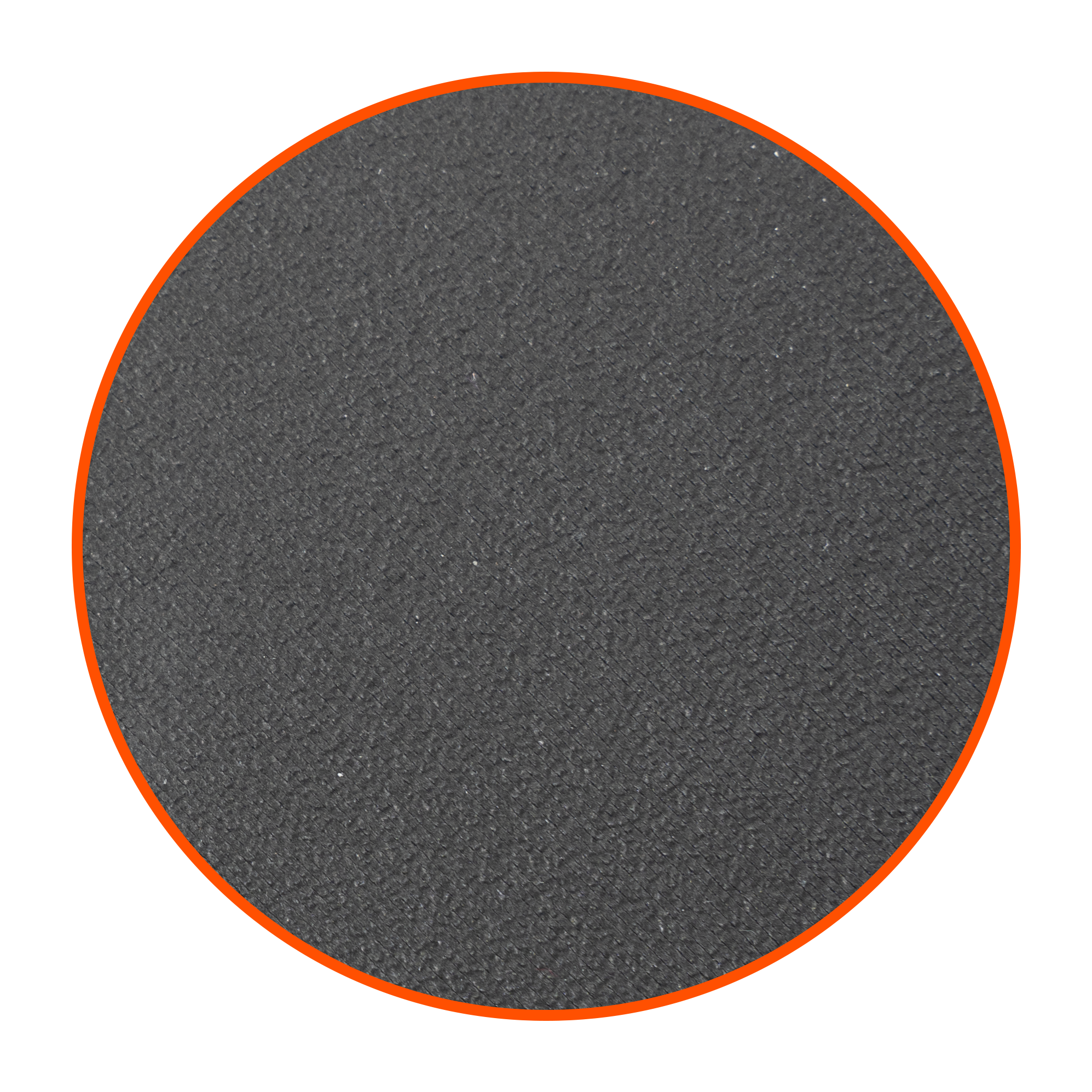

| PP steel sheet | The underside of a printed object |

The PP sheet is made for printing polypropylene (PP) since its adhesion to standard PEI sheets is generally very poor. The sheet comes with a matt texture, similar to the satin steel sheet with a PEI surface. The sheet is compatible with most polypropylenes, PLA, PETG and TPU, other materials may have insufficient adhesion and should be printed on our standard PEI sheets.

Main attributes

- Compatible with many types of polypropylene

- Made for printing without using a glue stick, PP tape and other means of increasing adhesion

- Slightly textured surface

- Double-sided! Both sides can be used repeatedly

- Easy maintenance and good adhesion qualities

Considerations

- Never clean the PP sheet with acetone! This will damage the surface.

- For good adhesion properties and easy print removal, clean the print surface with IPA before every printing, just as described in 3D printing handbook.

- Check the proper first layer height! If the Live Z value is too low and the first layer is too squeezed, print removal may be difficult and may damage the sheet.

- Some types of polypropylene may be prone to warping and require using brim or are suitable only for printing small parts and models with sparse infill.

- Keep the sheet as clean as possible! Any grease stain will decrease adhesion.

- Live Z value needs to be readjusted if you switch sheets. See Profily vyhřívaných podložek.

- Not scratch-resistant!!! Do not use metal spatulas with sharp edges to remove the prints. Be extremely careful when removing the print.

- Printing with Brim is recommended.

Maintenance

- Attracts fingerprints - A good indication of where your sheet is dirty/greasy and that you need to clean it.

- Clean with ~90% IPA when the sheet is cold. If ~90% IPA is not sufficient, clean with dishwasher soap. Do not leave the sheet wet! It has an anti-corrosion layer but is still not recommended.

- Never clean with acetone! It might cause damage to the sheet.

- Some types of paper towels may leave traces on the sheet (fiber pieces).

Filaments

We have done a lot of testing and compiled our results for you to use. To easily see how to prepare your sheet for any filament type, please see our Material table.

Prints don’t stick

If your print surface is perfectly clean and all grease has been removed by wiping it with a paper towel soaked in isopropyl alcohol ~90% and if the first layer height is set up perfectly, yet your print still does not adhere reliably to the print surface, check out Problémy s první vrstvou.

Keep in mind that polypropylenes in general tend to warp more than other materials. Sometimes warping may be so strong that larger models (or with dense infill) detach from the surface even over the best surface adhesion. If you experience such strong warping, we recommend using another type of PP for selected print - for example, our Prusament PP Carbon Fiber shows almost no warping at all. You can find more in the articles about polypropylene and warping.

Notes

After removing the 3D-printed object, you may notice a visible imprint on the sheet’s surface. This is only a visual change: it doesn’t leave any marks on the next 3D-printed parts and does not affect the printing properties in any way. Therefore it’s not considered a reason for a warranty claim.

As a result of the temperatures to which the sheet is exposed during printing, some parts on the bottom surface, which is in direct contact with heatbed, may become slightly glossier or with a different shade. This visual change does not adversely affect the printing properties and is also not considered a reason for a warranty claim.

|  |  |

| Example of visible imprint | Imprinted purge line | Shade change caused by heatbed |

Komentáře

Stále nemáte jasno?

Pokud nemůžete najít odpověď na vaši otázku, projděte si naše další materiály na webu.

A pokud nenajdete odpověď, pošlete nám zprávu na [email protected] nebo přes tlačítko níže.