- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- 日本語

- Home

- About your printer

- General Information

- FAQ - Extended buyers-guide

FAQ - Extended buyers-guide

- Printer description

- Printer features

- General Information

- Assembly manuals

- Buddy3D brand

- Customer support

- E-shop order creation

- Enclosure guidepost

- Error when placing an order

- Factory repair

- FAQ - Extended buyers-guide

- FAQ - Frequently Asked Questions

- FAQ - Orders

- Food safe FDM printing

- Glossary i3-Series

- Glossary MINI

- Glossary MMU2S

- Glossary SL1/CW1

- How do Prusameters on Printables work?

- Input Shaper (MK4/S, MK3.9/S, MK3.5/S, XL, MINI/+)

- LoveBoard status LEDs (MK4)

- MMU3 Compatibility

- Notify me when available - How the system works

- Order status

- Orders to the UK

- Original Prusa Enclosure

- Original Prusa Serial Number

- Packing i3 printer for return

- Packing Multi Material upgrade for return

- Packing SL1/CW1 for return

- Packing the Prusa MINI for return

- Payment error

- Payment options

- Photo and video documentation

- Printed Solid Service center USA

- Printer Handbooks

- Printer repair centers

- Prusa Academy

- Prusa Account creation

- Prusa Printer Upgrades

- PrusaAccount 2-step Verification

- Purchasing and managing licenses for Prusa Academy courses

- Refunds & returns

- SD cards and USB drives

- Shipping information

- Supplemental Statements valid on Prusa websites

- Types of printers and their differences

- Unpacking a CW1

- Unpacking an assembled i3 printer

- UPS backup for your printer

- VAT (Value Added Tax) & Customs fees

- Vouchers/Discounts

- Warranty

From both individuals and companies in the market for a 3D printer, our customer support receives a lot of questions regarding our printers and what it takes to get started with 3D printing. We, therefore, made this addition to our FAQ. We hope this guide can both provide some answers and assist in asking the right questions when purchasing a 3D printer. A side-by-side comparison of specs and numbers can not really inform such a decision. A 3D printer is a machine that can make almost anything you need, but the type of printer, material, and settings all depends on that need.

|  |  |

Resin (MSLA) or plastic (FFF) printer? I hear resin printers have more detail.

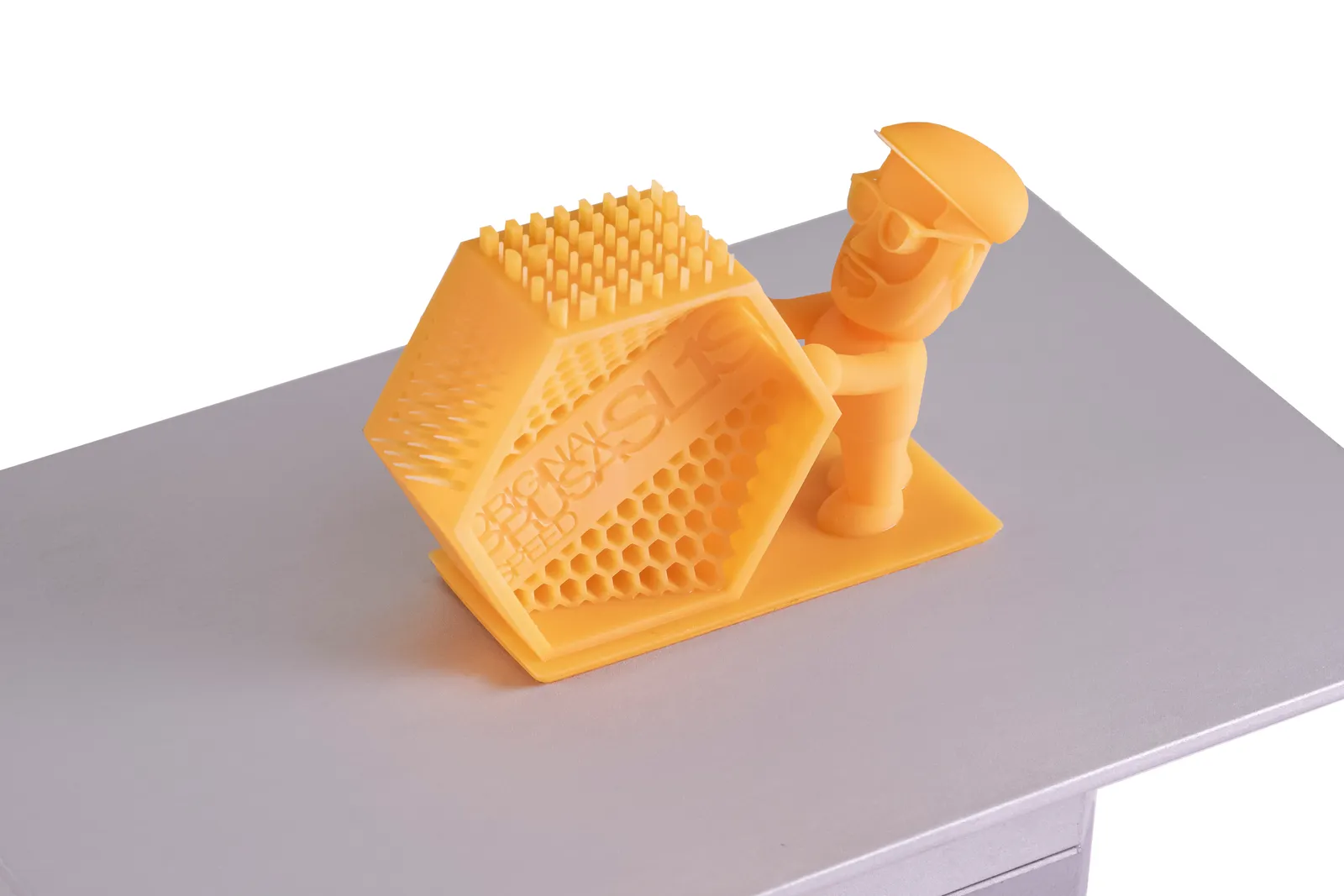

Yes, printers like the Original Prusa SL1S do have more detail but also have a smaller build-area. Resins are hard and tough, but most are brittle when it comes to impact resistance. FFF (Fused Filament Fabrication) printers like the Original Prusa MK4, Original Prusa MINI+, or Original Prusa XL have a wider range of materials available and also a larger build-space. You can also do multi-material printing, using our Original Prusa MMU3 (picture below), or one of the multi-tool versions of our Original Prusa XL.

While you will be able to achieve incredible detail with an FFF-machine, (M)SLA printers, as the Original Prusa SL1S, are commonly used in dentistry, jewelry, and printing awesome board game miniatures. You will know your needs best, but FFF-printing can be easier to get started with for a beginner.

Why an Original Prusa printer?

Our goal is to make 3D printing more accessible and embrace open standards. That means that all of our printers and software are open-source. We are continually working together with the community, listening to their feedback and ideas. Our aim is to deliver an outstanding 3D printer for an affordable price and make this amazing tool available not only to professionals but also to students and hobbyists. Therefore, we provide 24/7 Support for any questions regarding our machines and how to get started. In addition, we are developing this extensive Knowledge Base, to share our technical insights into 3D printing.

What kind of setup do I need?

This depends on your application and the number of printers. 1-2 printers can comfortably be in the same room as the operator, in for instance an office/studio setting. When printing PLA and PETG (two of the more common materials) there is minimal odor and noise. With a larger number of printers and/or manufacturing of ABS/ASA parts, it can be recommended to have a separate ventilated room or enclosure to avoid the noise and fumes this can produce. For Original Prusa MK3/S/+ and MK4, we offer our Original Prusa Enclosure.

We also offer solutions for remote control and monitoring of our 3D printers, our Prusa Connect and PrusaLink.

Our machines come both as pre-assembled or as a kit for self-assembly. The Kit comes with a detailed illustrated assembly-manual and is a great learning experience. The Original Prusa MK4 can take about 8-10 hours to fully assemble. The assembled printer just needs to be taken out of its box and after a quick setup, is ready to print.

What materials can I work with and what should I use?

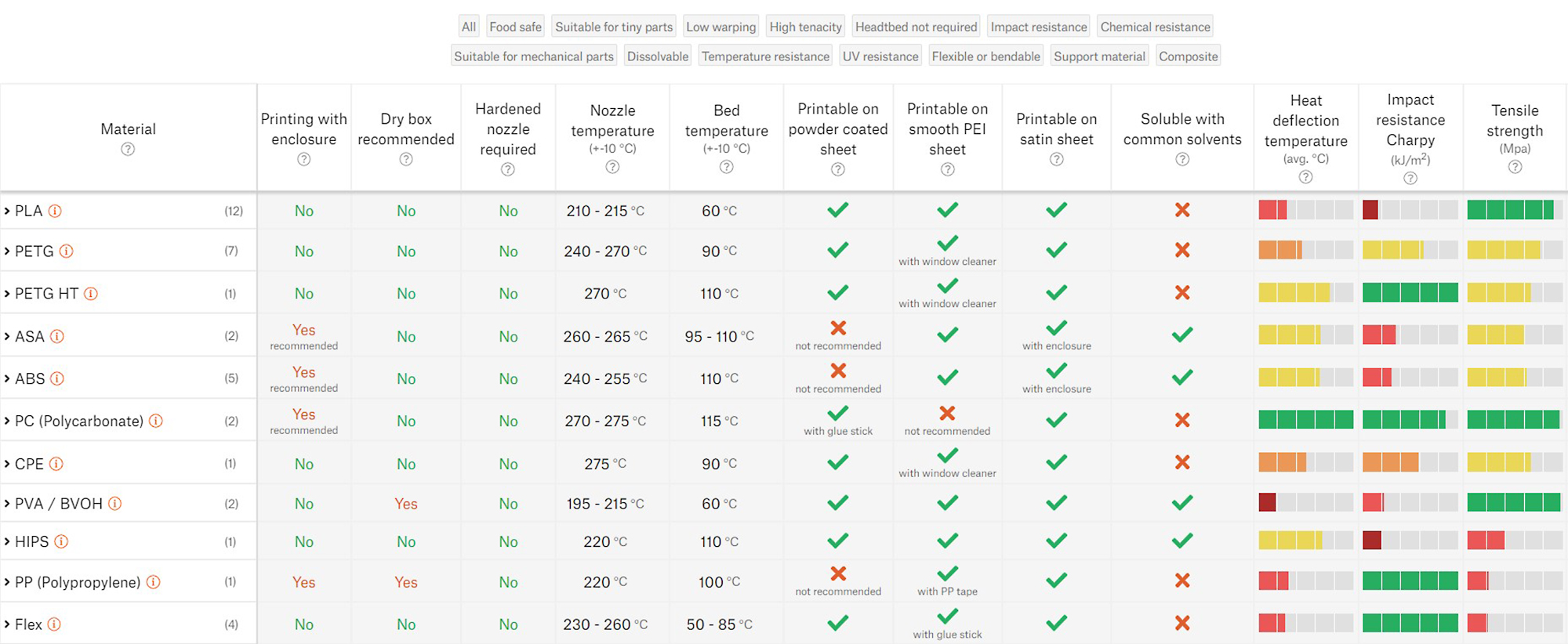

Currently, our FFF 3D printers will work with almost any printing-polymer that has a printing temperature below 300 ºC, which includes 98% of the materials out there. The most accessible are PLA, PETG, and ABS/ASA, but there are filaments infused with wood, copper-dust, steel, and much more. Your choice of material depends on the application of the parts you will be printing. PLA and PETG cover most needs. Our support can help you with this if desired. For a beginner, a good rule of thumb is; PLA for pretty things and PETG for functional things. We have developed an extensive Material guide to assist in finding the correct material and how to print it.

Our machines do not print metal, but the parts printed on our FFF printers can be made into metal through various methods. Moreover, there are robust polymers out there, like Prusament PC Blend, that could be a substitute, but if it is mainly metal components you need for your application, perhaps a FFF 3D printer is not what you need.

We also manufacture our own filament, Prusament. With its premium-grade materials and thorough testing, we a reaching a manufacturing precision of +-0.02mm, on 1.75mm filament. This makes it probably one of the best filaments in the world these days.

What is the process from design to a finished print?

This depends very much on the part, but simple objects like fittings, jigs, and cases for electronics can be quick for an experienced designer to make. We offer courses in our Prusa Academy for 3D modeling, designing, and printing.

Printing time will also depend on the size and material of the part. In most cases, a print will be ready for use within 2-24 hours of printing.

Among multiple repositories of free 3D models, we offer our own Printables repository.

How can you guarantee a good print quality?

Rigorous testing and a large community dedicated to high print quality; We have one of the largest FFF print farms in the world with around 600 printers running 24/7. We actually also hold the Guinness world record, for the Most 3D printers operating simultaneously, with 1096 3D printers operating at the same time in one room.

This experience and our beloved community spread across forums and social media, in multiple languages, keeps us on our toes, and assure we know how our designs work on a large scale. Our printers are also by large manufactured using our own printers, so we too rely on their reliable operation. With all of the plastic parts on the printer being 3D printed, we are able to iterate quickly and provide upgrade-options our users can print themselves.

We also develop and update presets and printing profiles for our open-source software, PrusaSlicer. More on that later on.

What kind of training/expertise is required?

There is a lot to learn, but the learning curve is gentle, and anyone can be printing with little effort. We strive to make it as smooth as possible. Our printers come with a detailed instructional handbook and we provide extensive documentation through our courses from our Prusa Academy, through the platform you are now reading, our blog, and our YouTube channel, informing on every aspect of our machines and 3D printing in general. Our customer support team can also help you with any technical questions or issues.

Does the printer come with any software and can I test it?

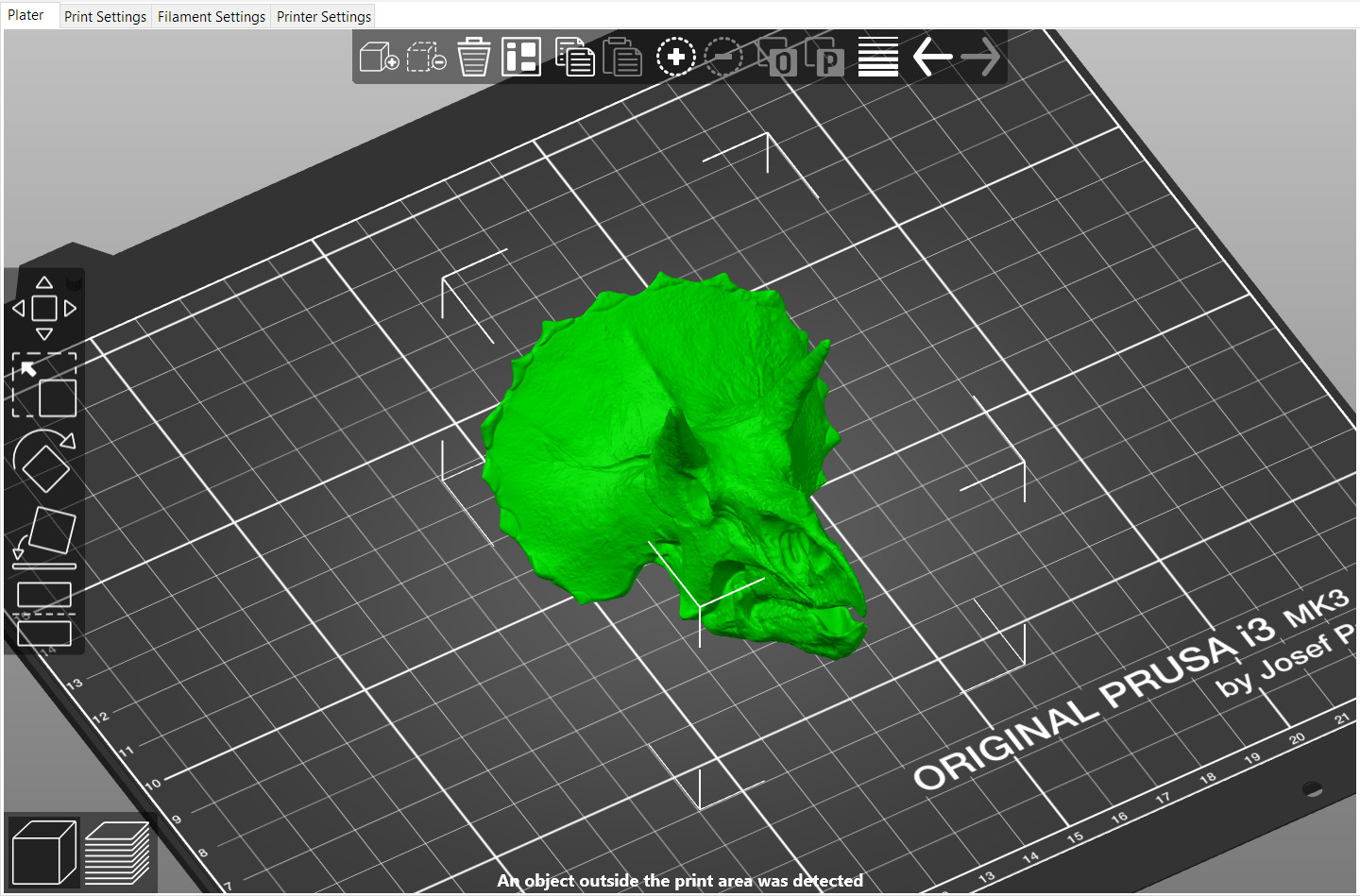

Our slicer software PrusaSlicer is free and open-source and can be downloaded here. It is a powerful tool to convert your 3D models into a format the 3D printer can read (G-code). Getting started is as easy as importing your model and exporting the G-code, using our presets. If you need something more specific for your application, PrusaSlicer has a lot of advanced features like custom supports, hollowing of models, modifier-meshes, and more. You can even do some basic 3D modeling. It is also fully documented.

|

| Plater-view of PrusaSlicer |

However, we do not develop dedicated modeling/CAD software, but we do have some information on it. We are avid users ourselves, after all, but the choice of software is so much down to personal preference and experience level. There is a great amount of 3D programs out there, from free to very expensive. Your choice depends on your needs, but if you are just starting out you should look to something with a large user base or community. Then you will probably find a tutorial for most operations and tasks, or be able to ask the community for help and advice.

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.