What happened?

The message "Extruder preheat error: Check the heater and thermistor wiring for potential damage" is shown when the printer is unable to heat up the nozzle more than 2 ºC for 20 seconds. The printer starts a safety feature, which instantly kills the heating process and displays the message on the screen. The printer then waits for the user to inspect all parts and if needed fix the issue.

Error name: Hotend preheat error

Error code: #17202

How to fix it?

Most often, this error happens due to wiring damage or connection issue on the hotend heater cable. Less often, it might be caused by the hotend thermistor wiring and connection.

A visual inspection

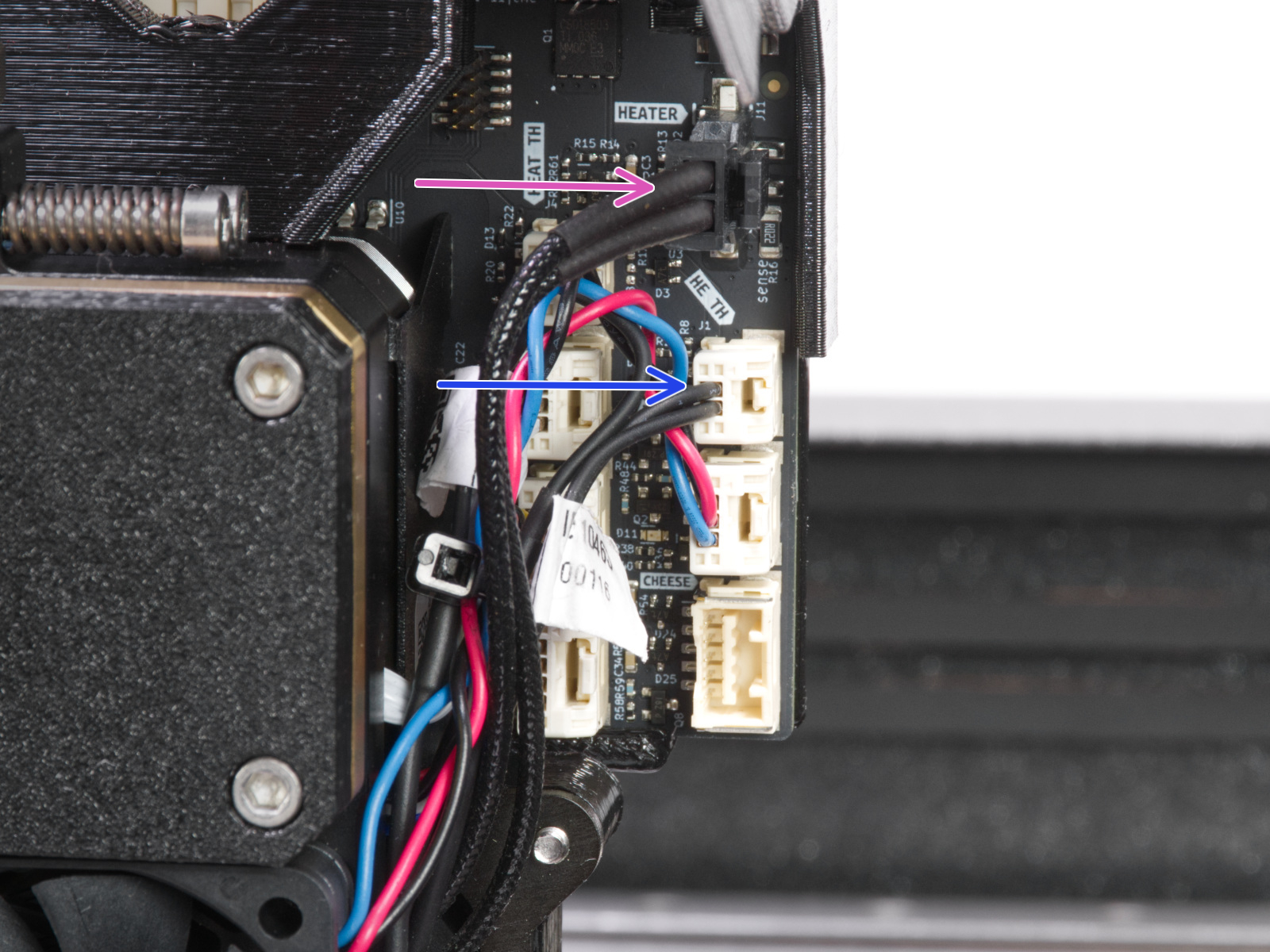

Before breaking out the multimeter you should check the Dwarf board, where the thermistor and heater reside, to ensure that no wires have broken off, or are disconnected.

- the filament is unloaded from the extruder

- the printer is turned OFF and unplugged from electricity

- the hotend and the heatbed are cooled down to ambient temperature

Place an empty Prusament cardboard box approximately to the front center part of the heated. Move the Y-axis all the way to the front side of the printer, and move the extruder approximately to the center of the X-axis.

Open the dwarf-cover-door to access the Dwarf board.

Check that all the connectors are secure in their sockets, according to the picture below. Focus on the thermistor and heater cables. Though unlikely, rough shipping or handling could have shaken the heater or thermistor cables loose.

Checking the resistance

The table below describes the correct resistance for each part, as well as what scale you should set your meter to. The hotend thermistor is rated to be 100 kΩ at 25 °C. To be realistic, with a varying temperature between 20 °C and 30 °C, you can expect a wider range of readings (~80-125 kΩ).

There can be micro-fractures in the cable, breaking the connections only at certain positions. Therefore, try to move the cable a bit while doing the measurement and see if the value changes drastically.

Part |

Resistance |

Multimeter scale |

|

Hotend thermistor |

[80 kΩ - 125 kΩ] |

200kΩ |

|

Hotend heater |

[12.3 Ω - 15.1 Ω] |

200Ω |

10 comments

There are two extruders, which one is giving the error.

How to clear thd error ?

Place an empty Prusament cardboard box approximately to the front center part of the heated. Move the X-axis all the way to the front side of the printer, and move the extruder approximately to the center of the X-axis.

Correction:

Move the Y-axis all the way to the front side of the printer, and move the extruder approximately to the center of the X-axis.