What happened?

During Filament loading, either to the MMU unit or to the Nozzle, if the filament does not reach the SuperFINDA or is not detected, the printer will show an error.

How to fix it?

FINDA

Follow this guide to make sure that your superFINDA is working and has been properly calibrated: Réglage et dépannage de FINDA.

Assembly

- Check if the filament has been grabbed by the idler/pulley. In case it has not, the filament is too far back.

- Make sure that the two spring screws on the sides of the MMU unit are properly tightened.

- Inspect the filament spool and the buffer for excessive friction or filament jam. Make sure the filament can move freely.

- Go over the assembly manual and verify if the barrel is in the correct orientation.

- Check the pulley gears for any filament remains, and check if the teeth are clean.

- Check that the corresponding pulley inside the MMU unit is properly aligned with the filament and is clean.

Selector

- Verify if the selector is in the correct position for the given filament number. After several unsuccessful retries, the selector will re-home.

- Check the selector for any filament remains and filament strings accumulated.

- On the MK3.5/S, MK3.9/S, MK4/S, and CORE One, go in the printer menu to Info - Sensor Info, and check if by passing a filament through the FINDA, the status will change.

- On the MK3/S/+, go to the printer menu to Support - Sensor Info, and check if by passing a filament through the FINDA the status will change.

Filament

- Make sure that the PrusaSlicer settings chosen match the filament you are using.

- Check if the filament needs to be dried: Séchage de filament.

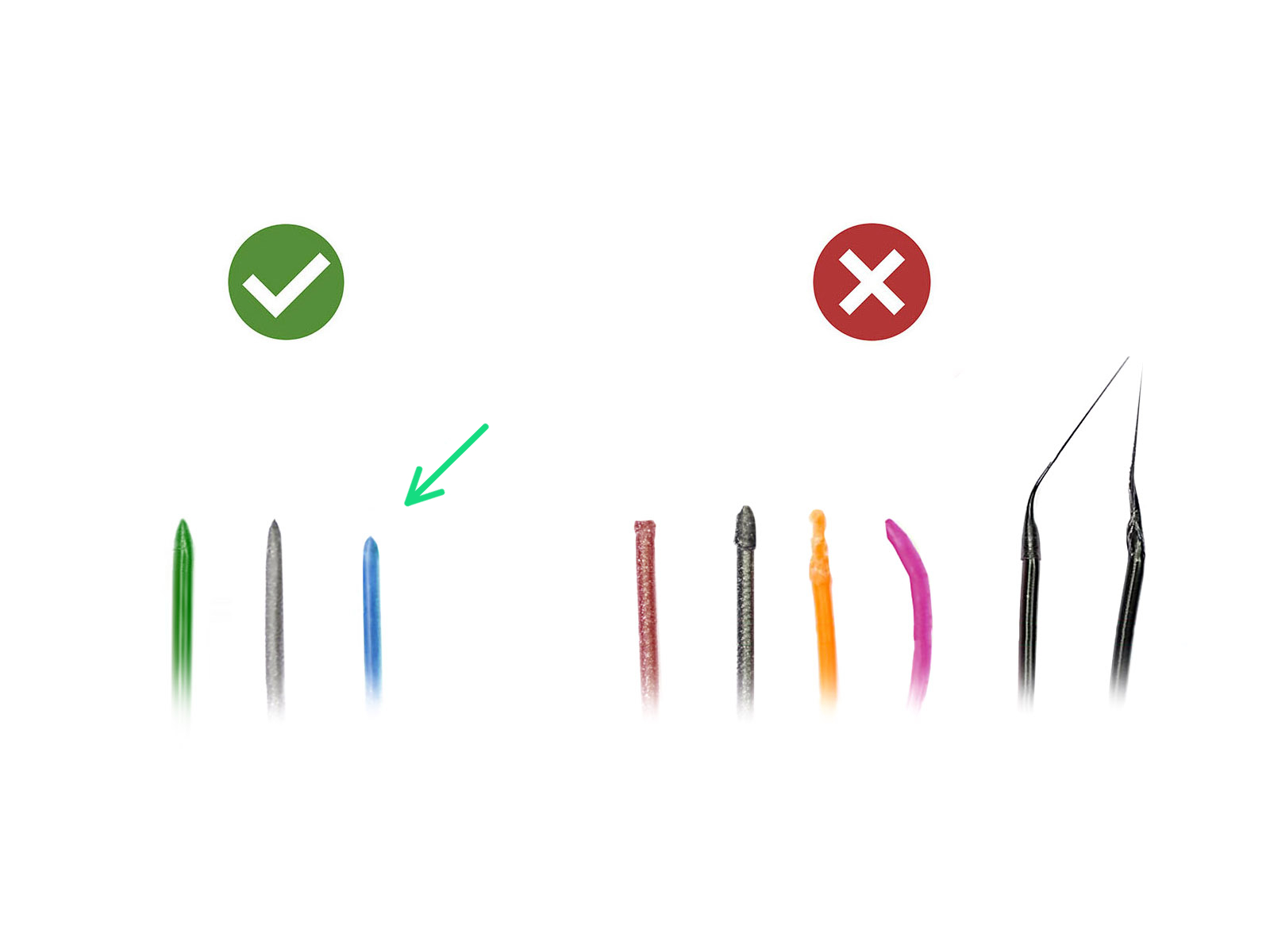

- The filaments must have a sharp tip in order to load properly into the printer. If the tip is deformed, bent, or larger in diameter, cut it off.

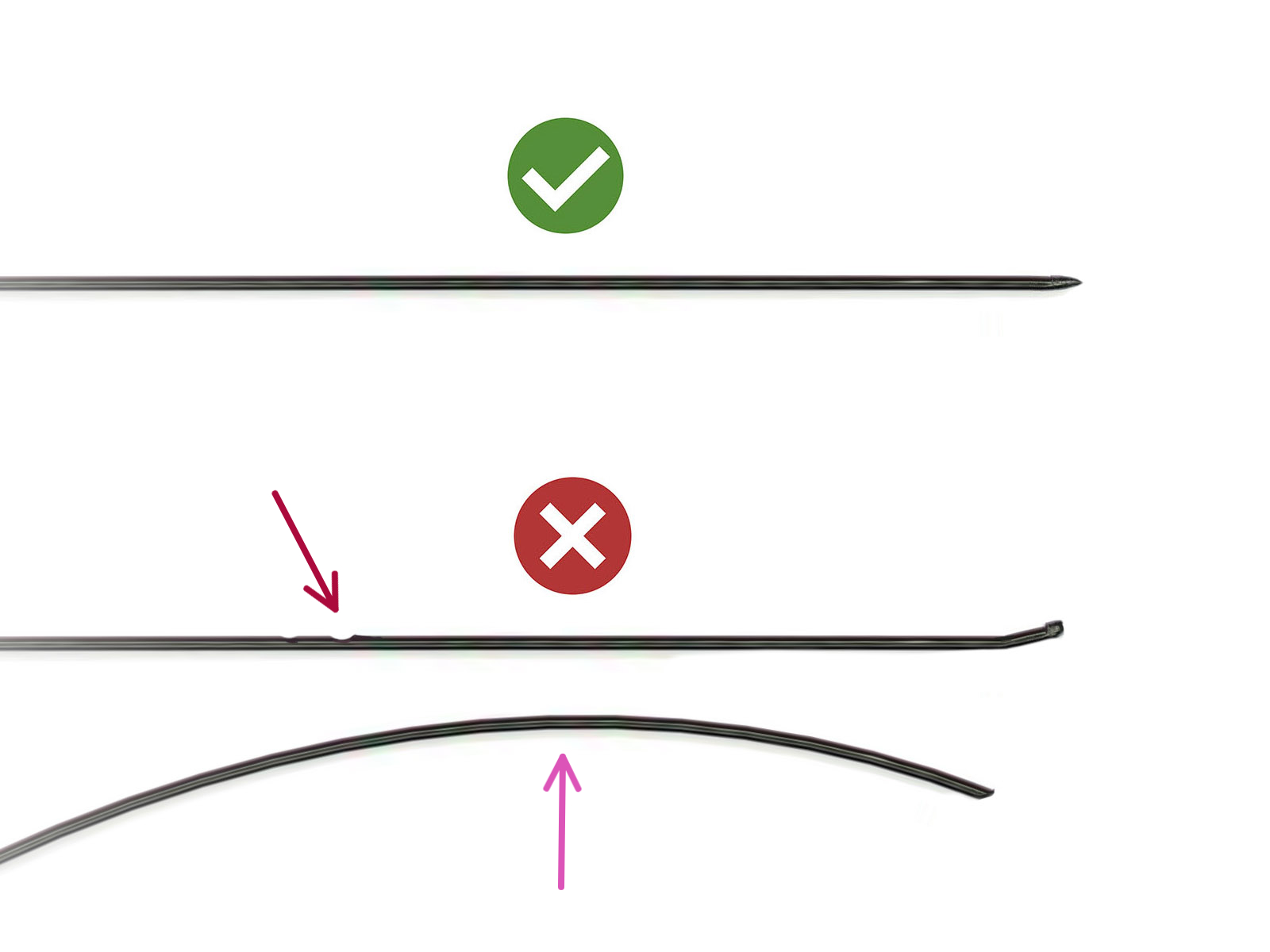

- Inspect the last 40cm (15") of each filament. Make sure there are no dents in it.

- If the filament is still not being pulled, check the assembly.

|  |

Cet article vous a-t-il été utile ?

Cette action n'est disponible que pour les utilisateurs enregistrés. Veuillez vous connecter.