Preheat error can happen with either with your Nozzle or Heated bed. So 1st make sure with which of these you have the problem.

"Heatbed preheat error" (Heatbed)

Things to check:

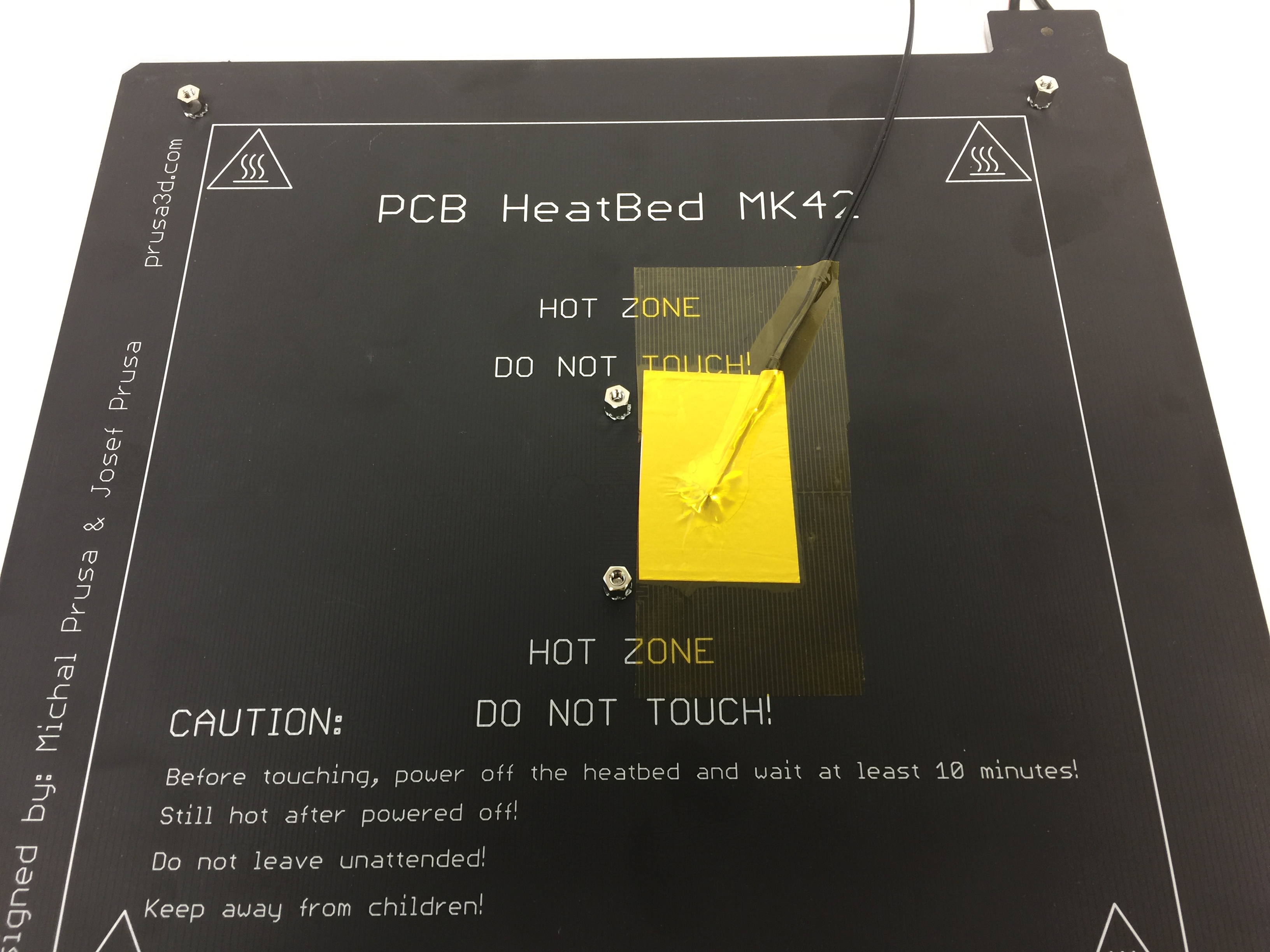

- Make sure that your Heated bed thermistor is properly seated under the Golden Kapton tape (photo below)

- Remove the cable cover from the back of the heated bed and inspect the leads to ensure they are still intact and soldered securely to the pads

- For MK2/MK25: Make sure the heatbed connector is fully seated into the socket on the RamboMini - You should routinely check this in general!

- If you've checked all the above and everything is in order. Please flash to the latest firmware.

- Would the issue still persist, then there is for sure something wrong with your heater or thermistor. In order to find out which one of these is malfunctioning. Do the simple test described below.

How to find out if your Heater or Thermistor is defective for your Nozzle/ Heatbed?

It is not very common, but there is a chance that extensive printing damaged your heater or thermistor.

The easiest solution is to take a hairdryer and blow hot air at the Hotend or Heatbed. During this process just check if there is any temperature change on the LCD. If there is a change, it means that your thermistor is working, which means that the heater is damaged. If there is no change at all, your thermistor is defective.

Checking voltages and resistance

Using a multimeter would be the most efficient and accurate way of determining if the components are good or not. It is quite straight forward. See Multimeter usage for how and what to measure.

7 comments

The first time, doing a flash to the newest software solved the issue for some prints, but then a thin element fell, it started printing in the air, and I had the usual "Heatbed preheat error again".

However, what solved it for me was starting the print - seeing that the heatbed wasn't warming up - and manually "kickstarting" the heatbed with a hairdryer. After that, I heated it up this way a few degrees, it did the rest itself and is now keeping a steady temperature.

As this has given me many grey hairs in the past, I wanted to share this solution here asap :) hope it can help someone.