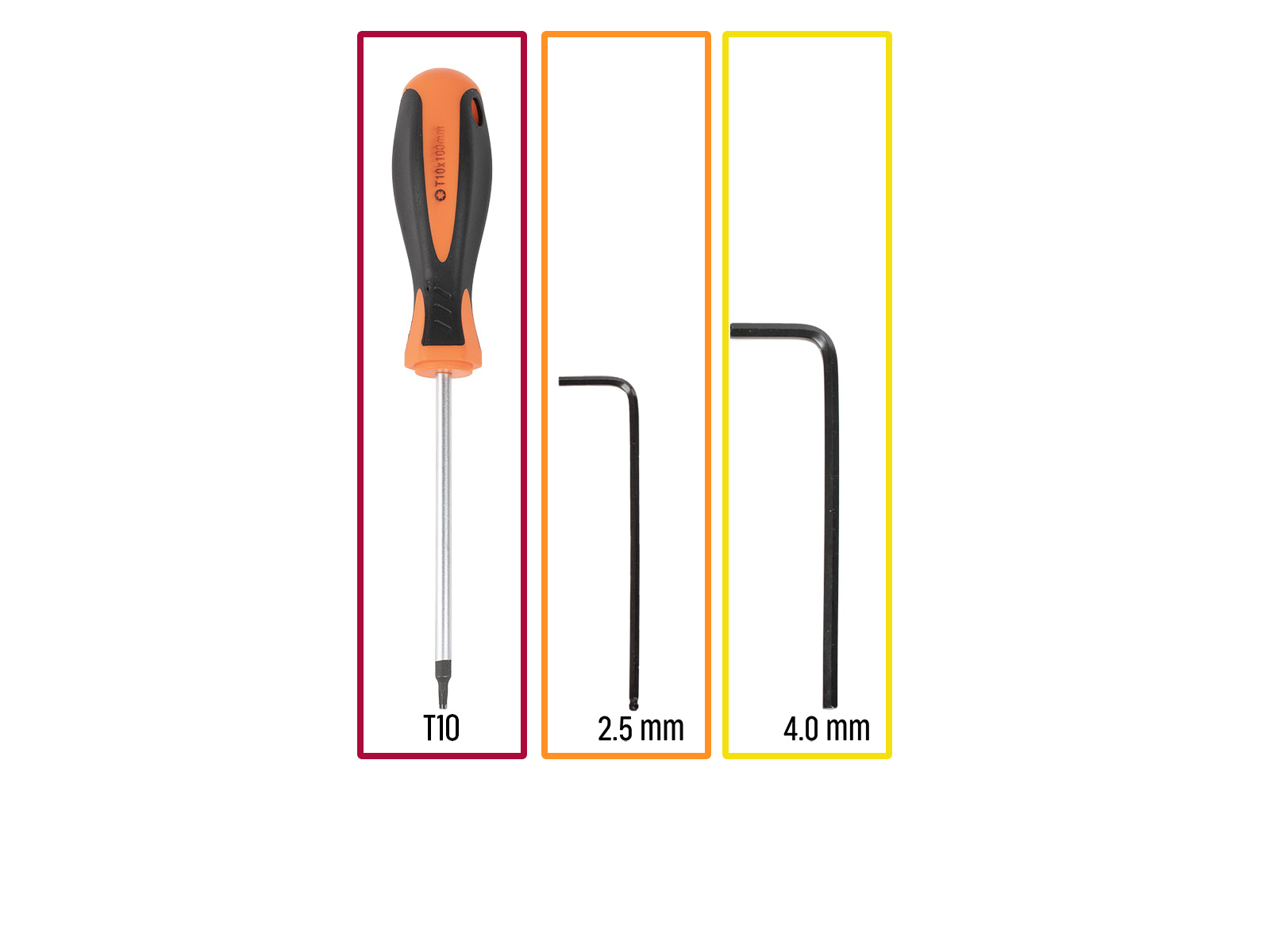

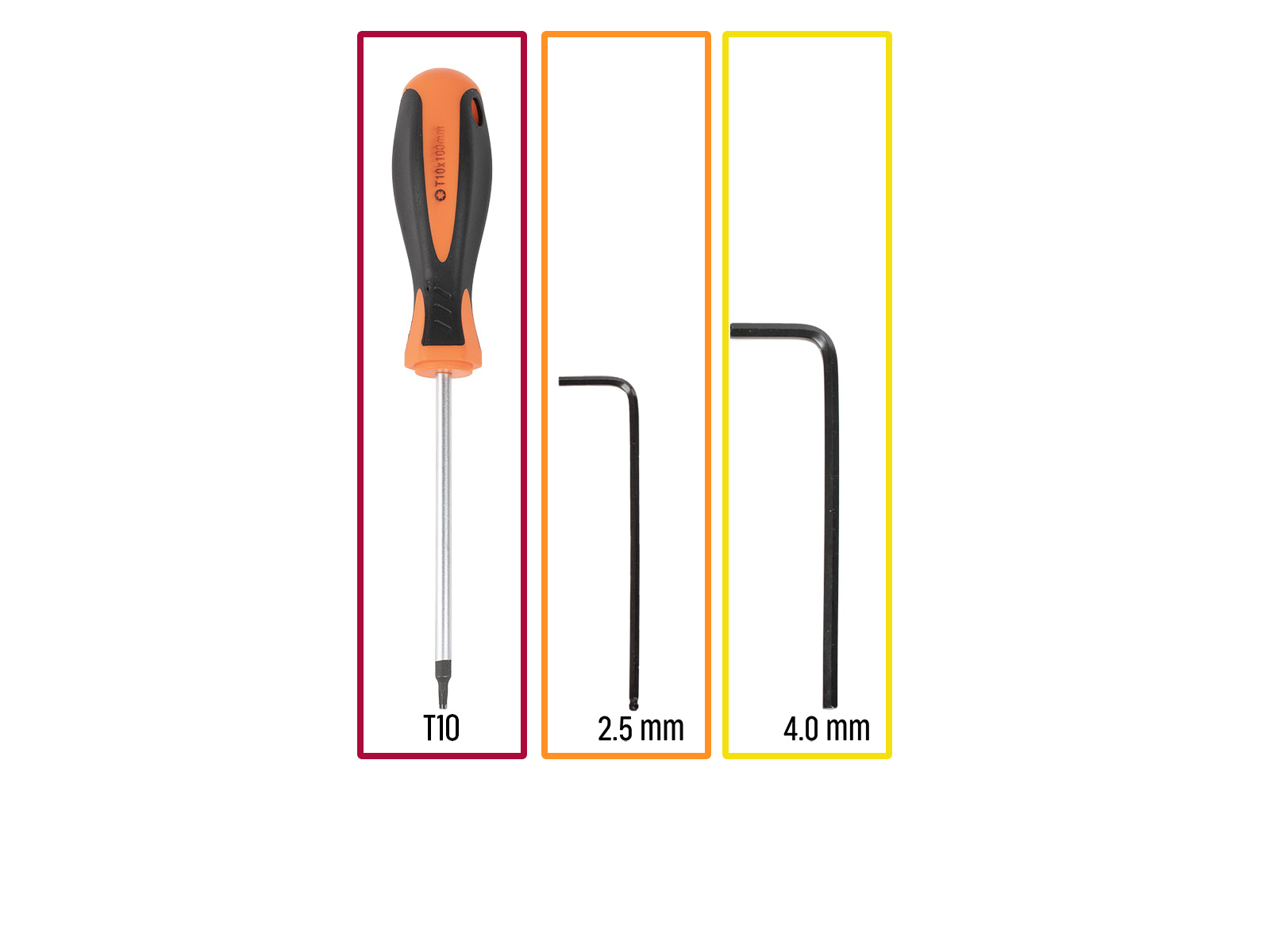

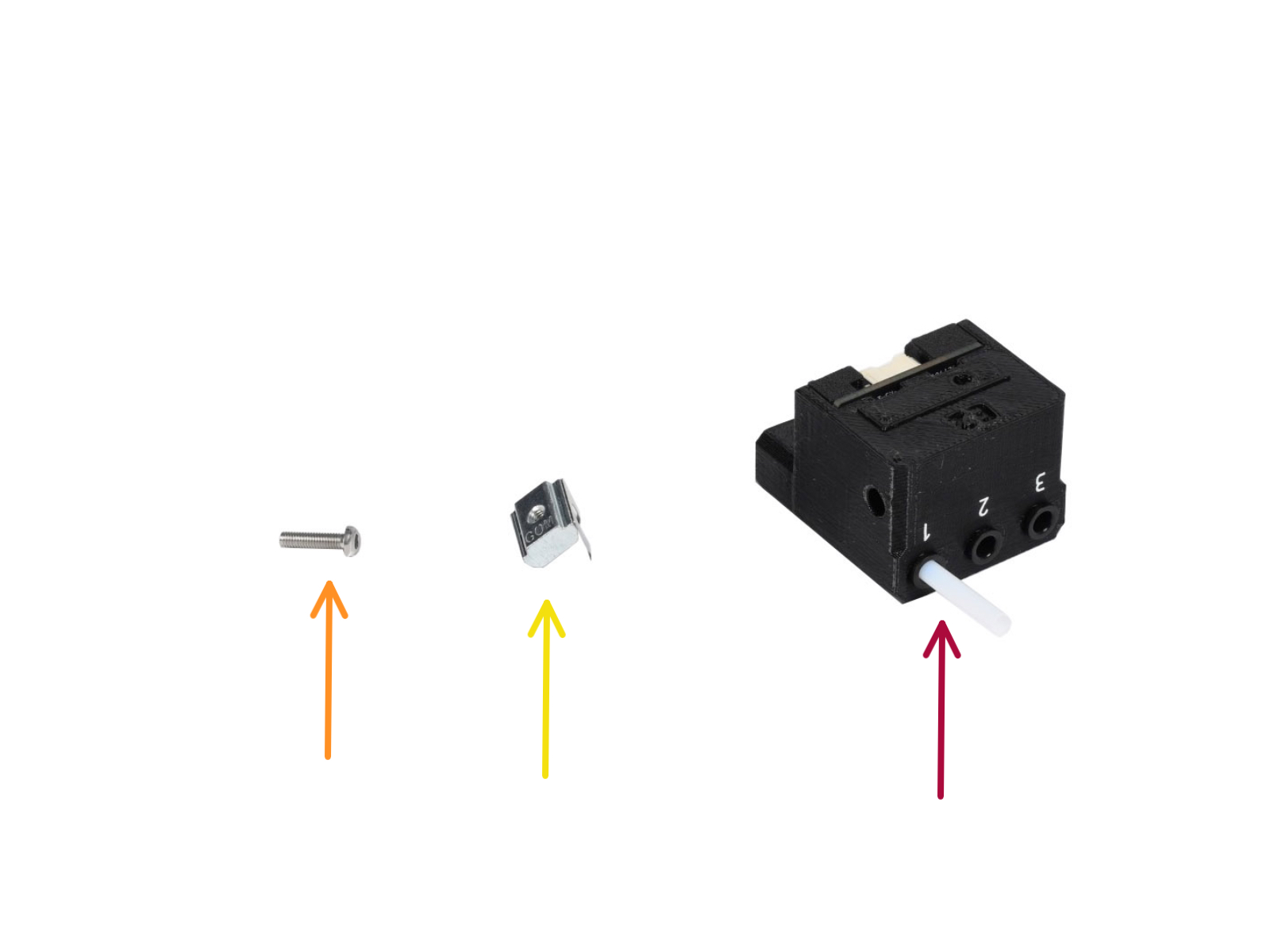

⬢For this chapter, please prepare:

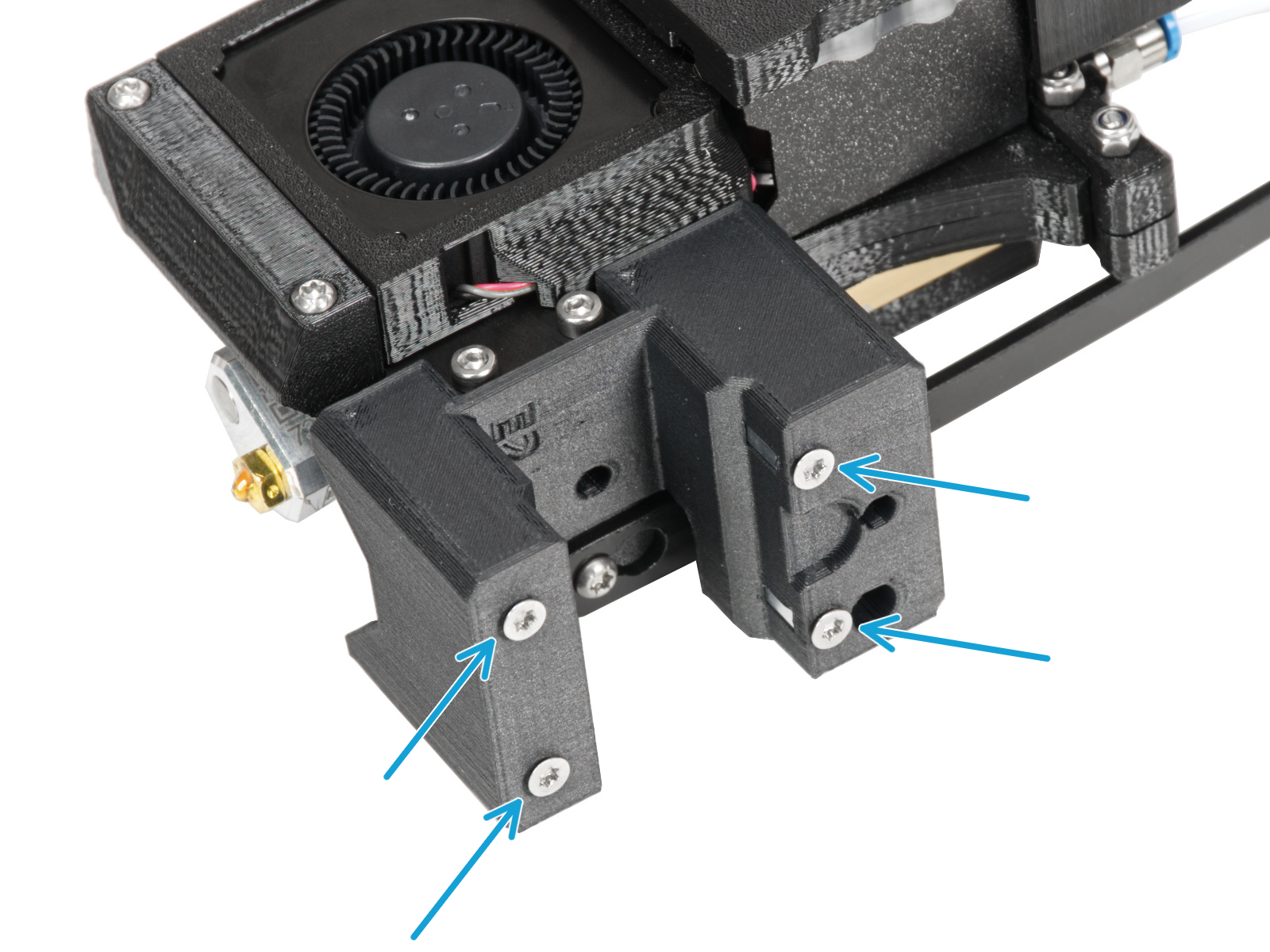

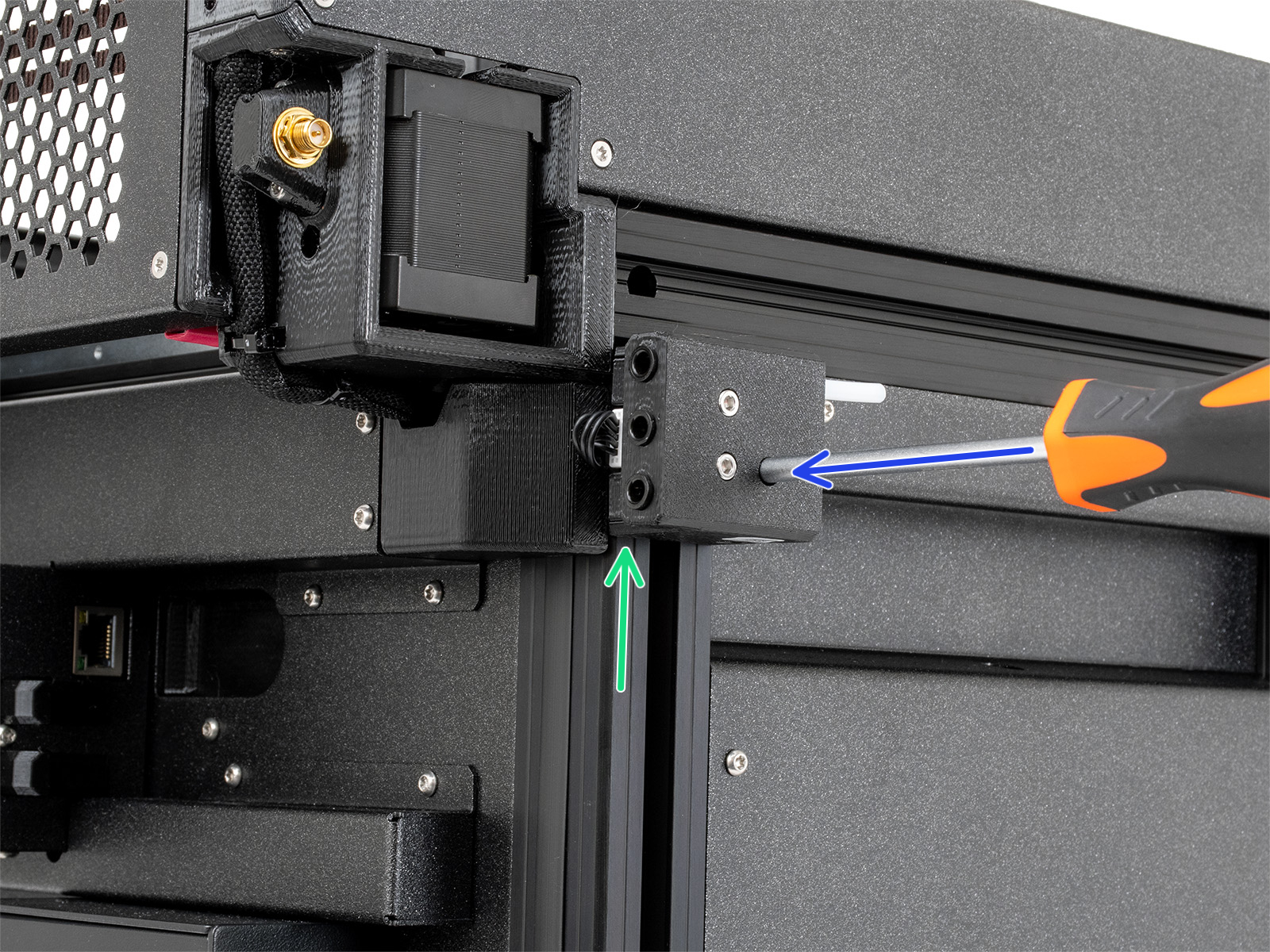

⬢T10 screwdriver

⬢2.5mm Allen key

⬢4mm Allen key

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.