⬢

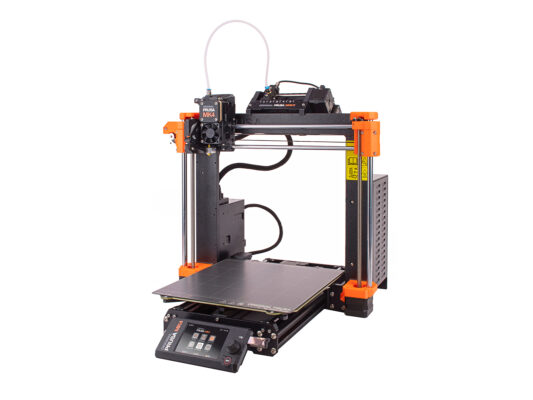

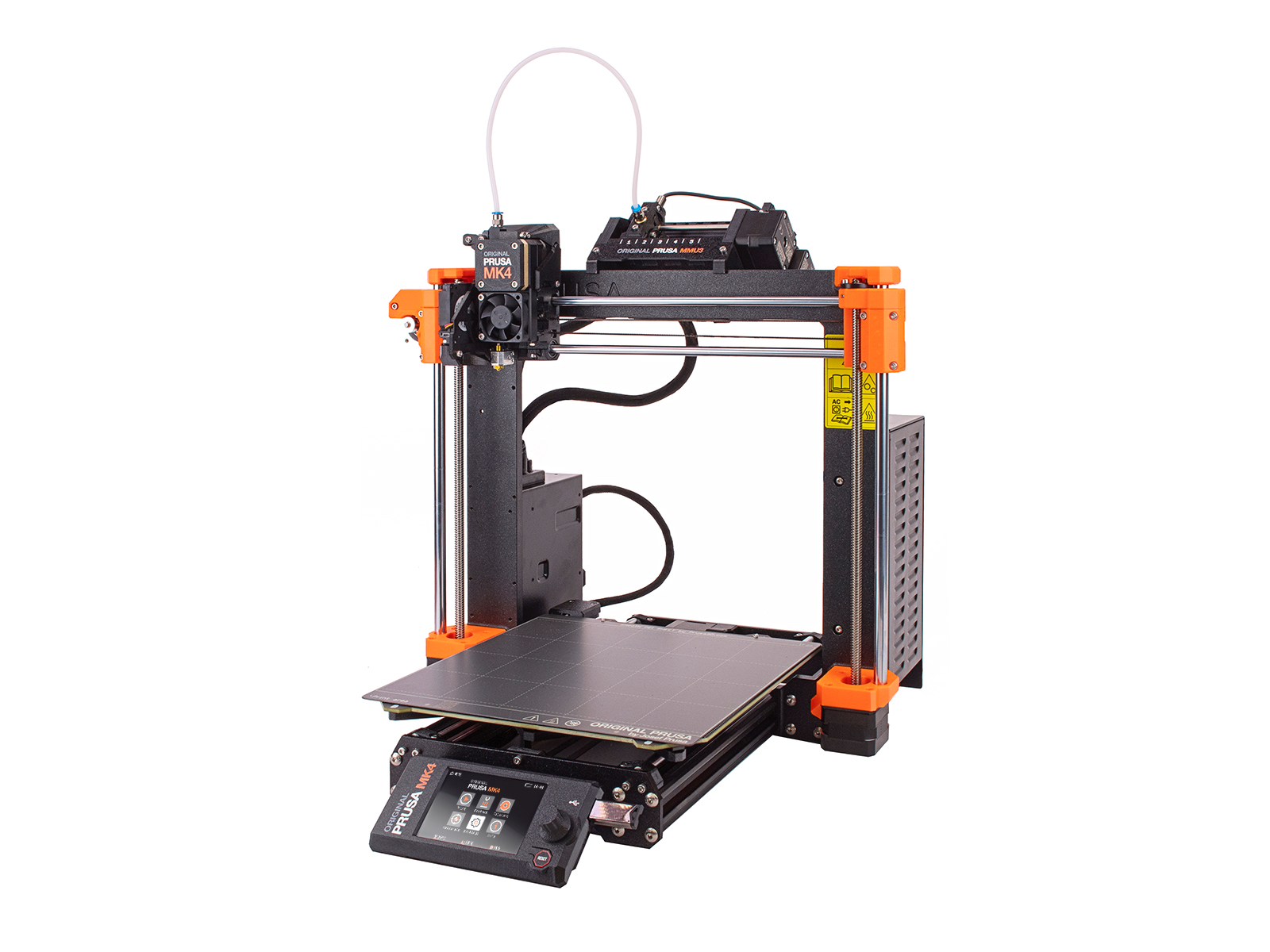

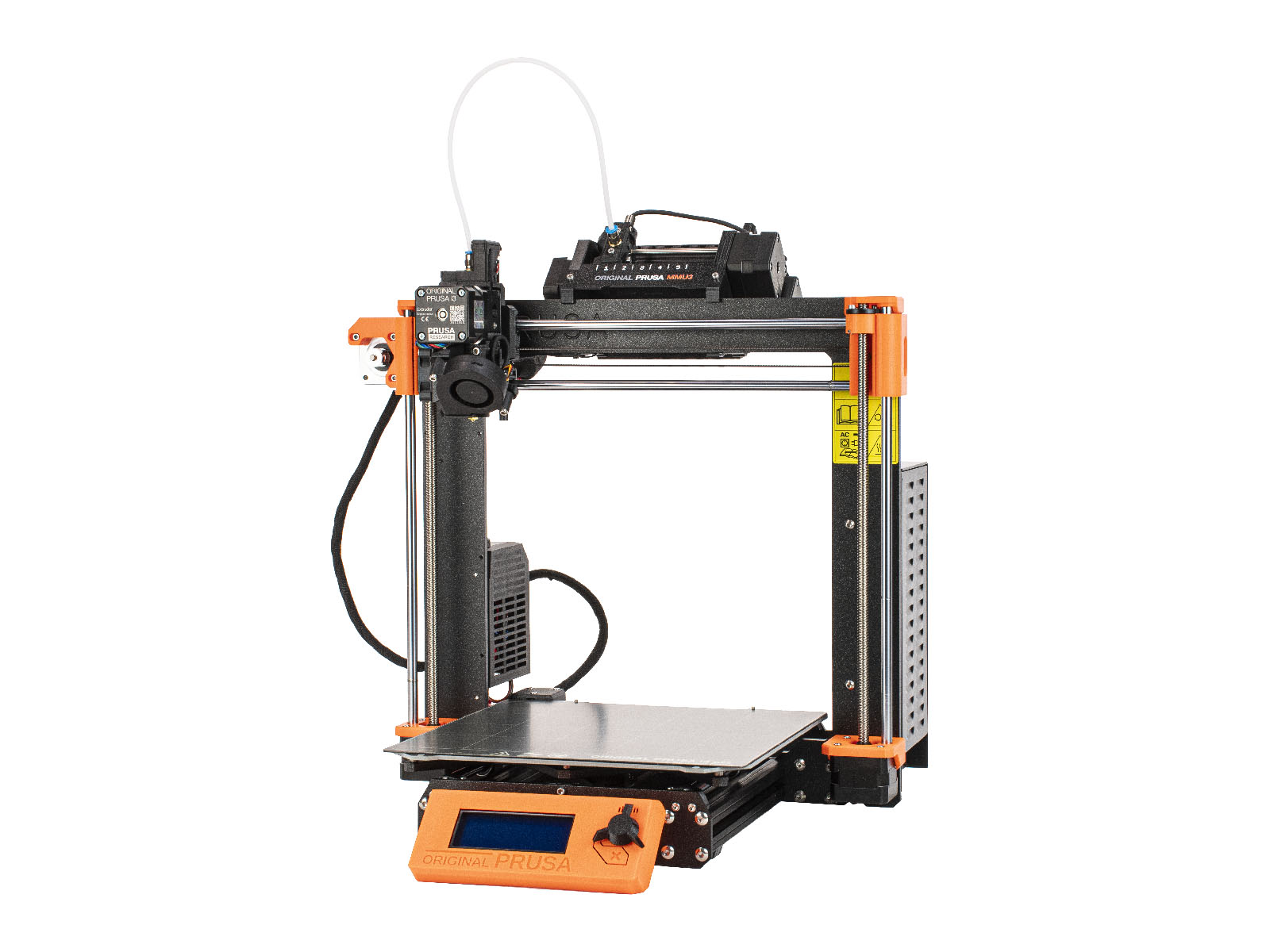

In this chapter, we will assemble the spoolholders, but before we proceed, note there are two types of the spoolholder.

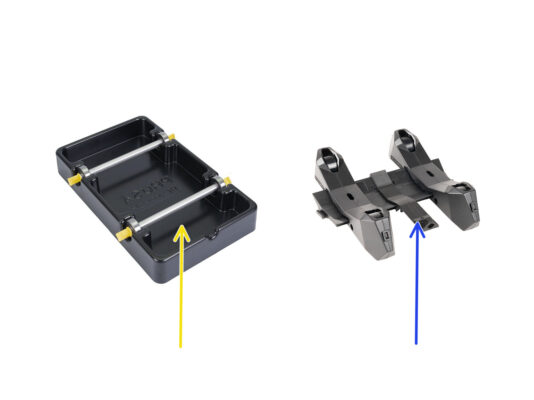

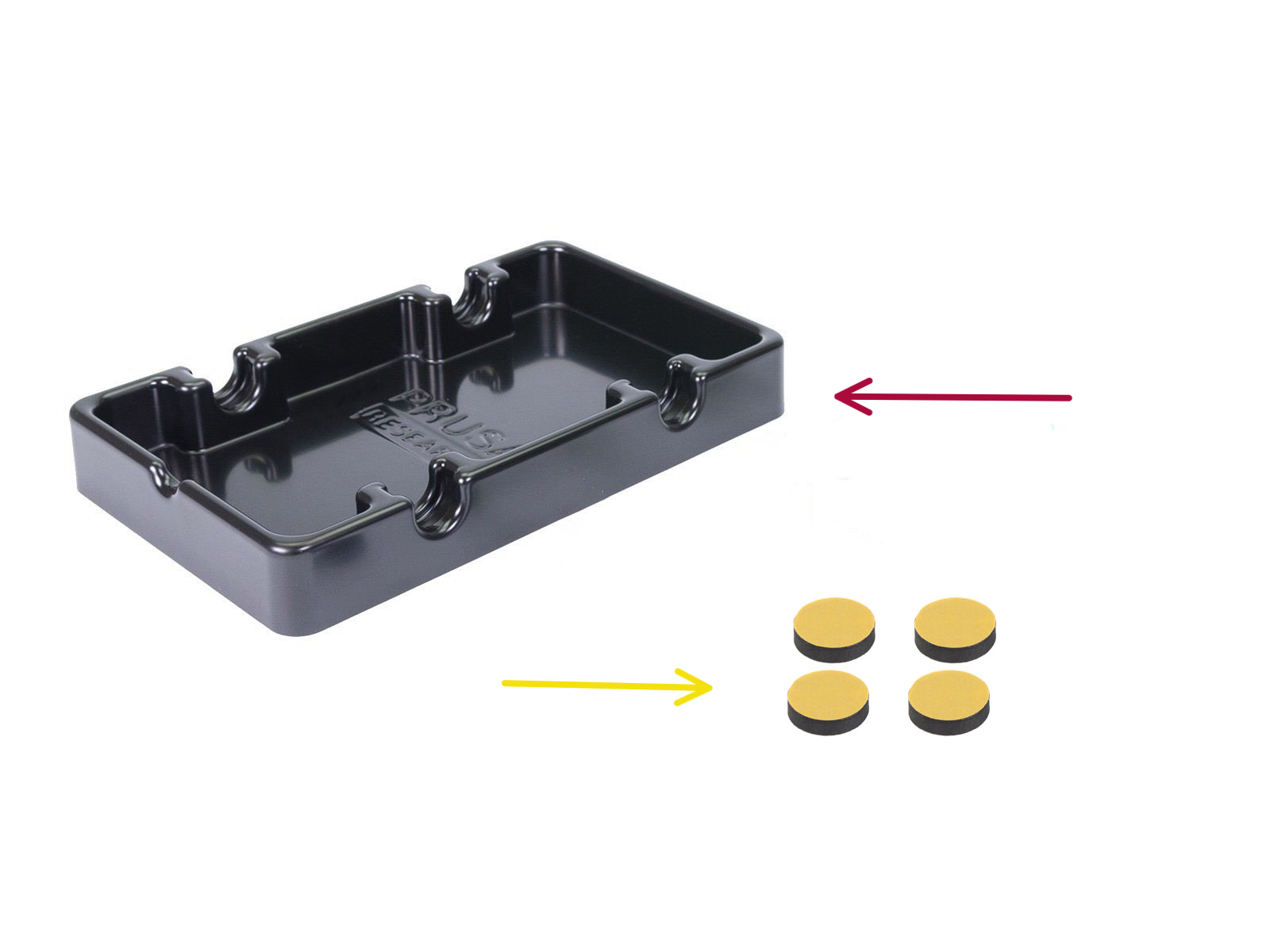

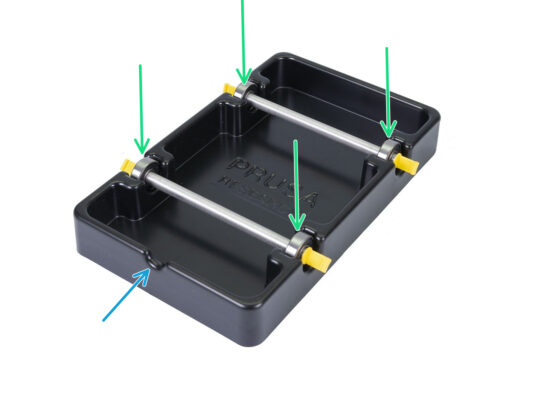

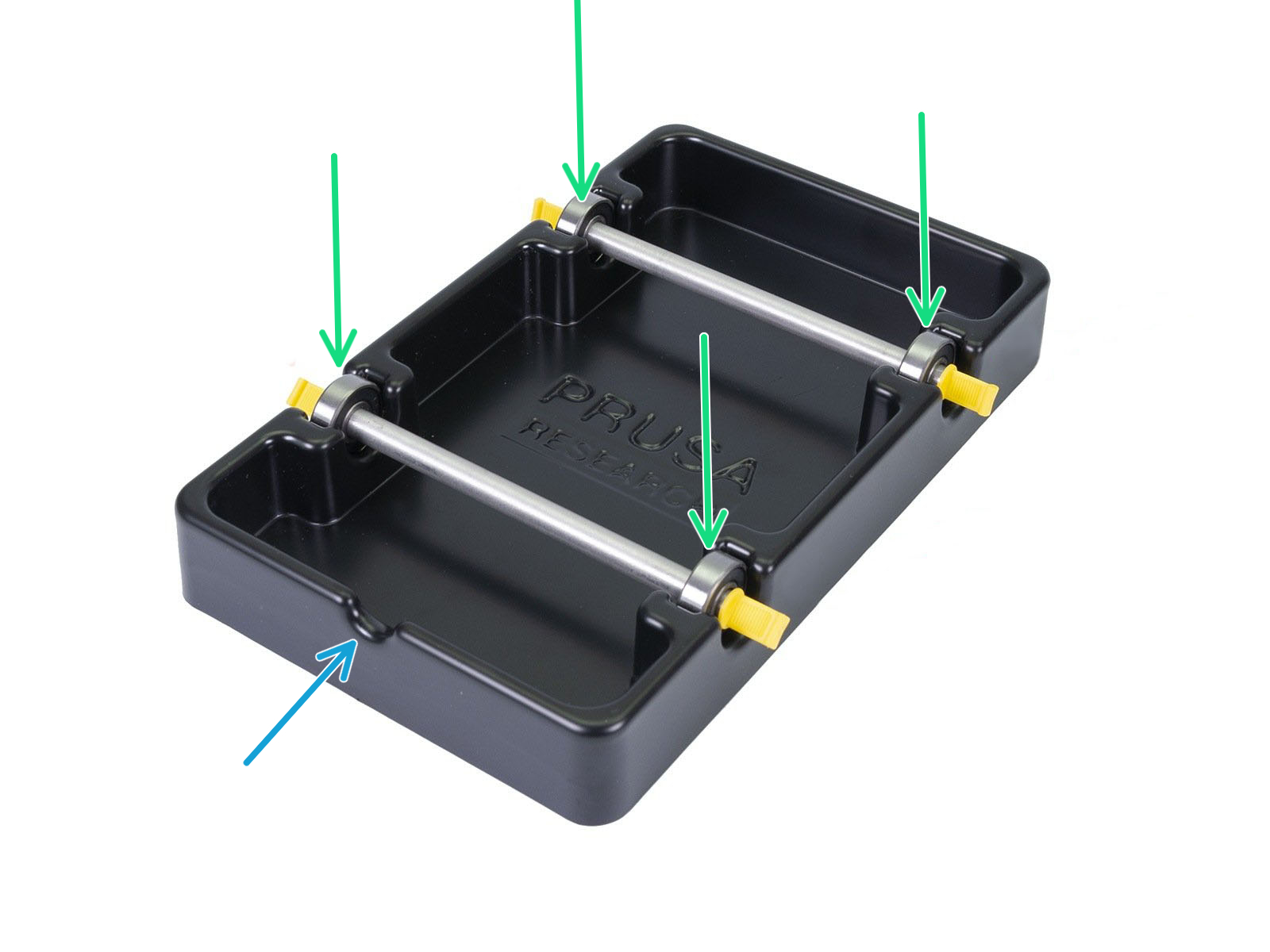

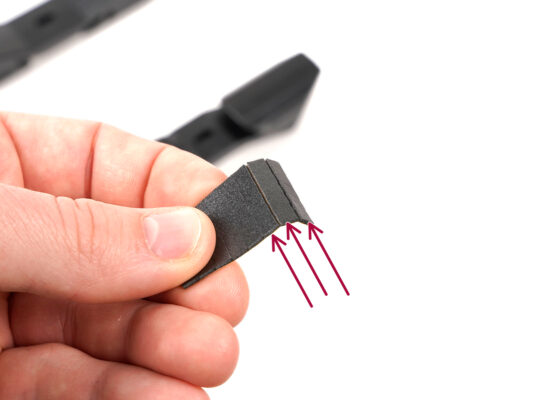

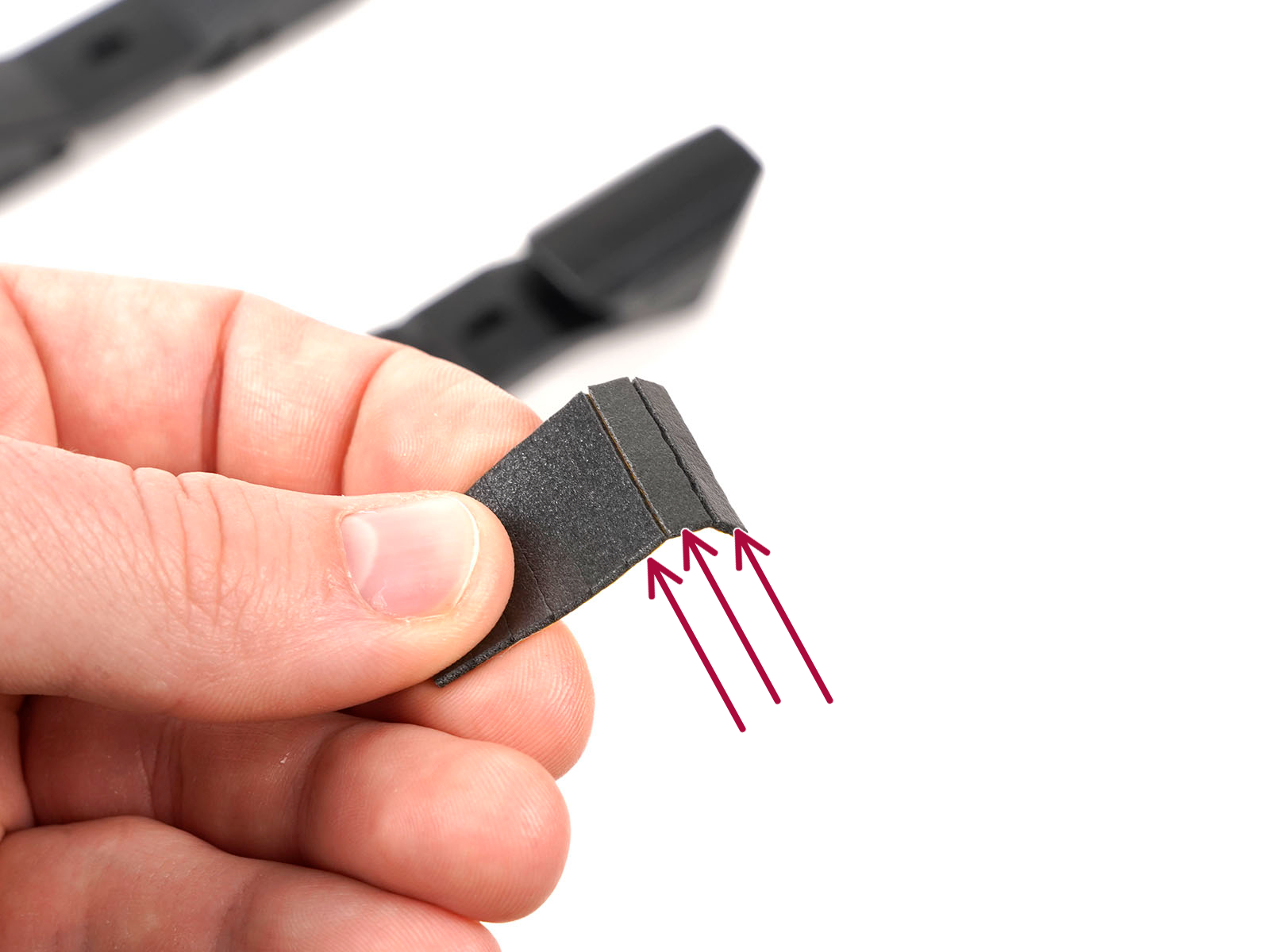

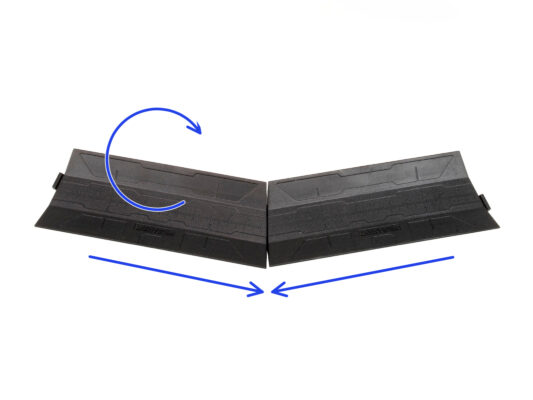

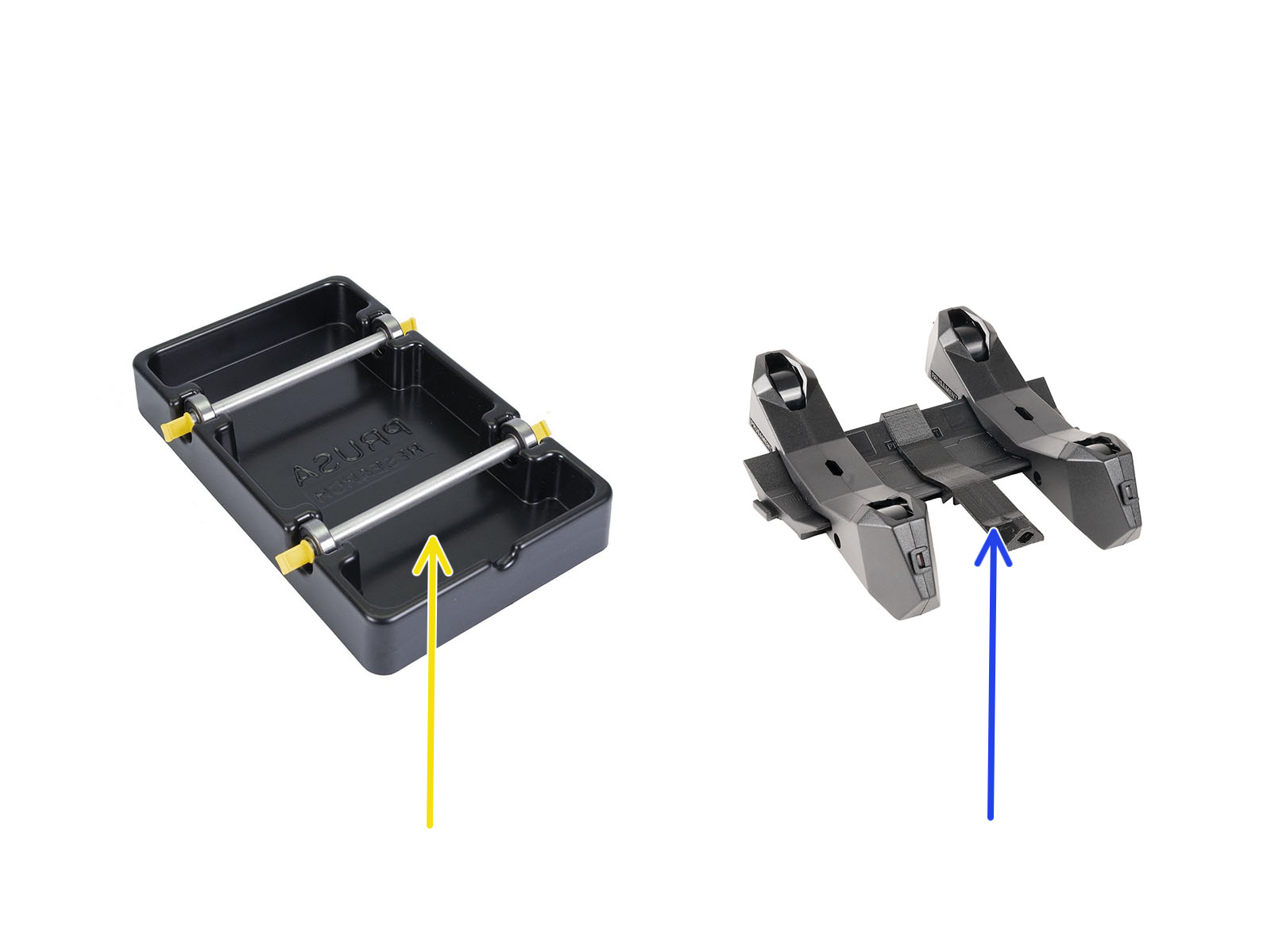

Inspect the box your kit came in. If the large portion of the box is occupied by the rectangular black trays, you have the first version, the older vacuum-formed spoolholders.

⬢

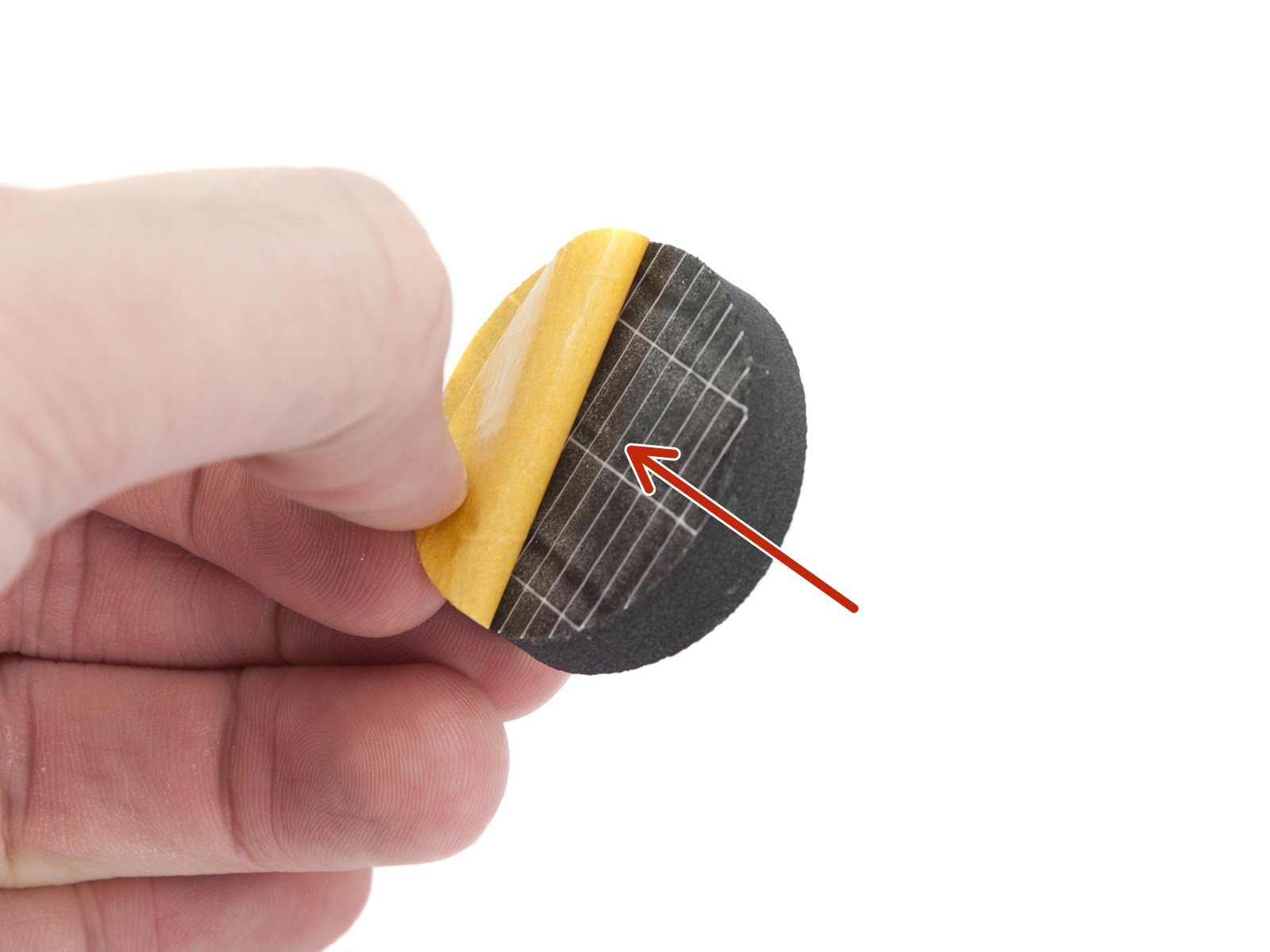

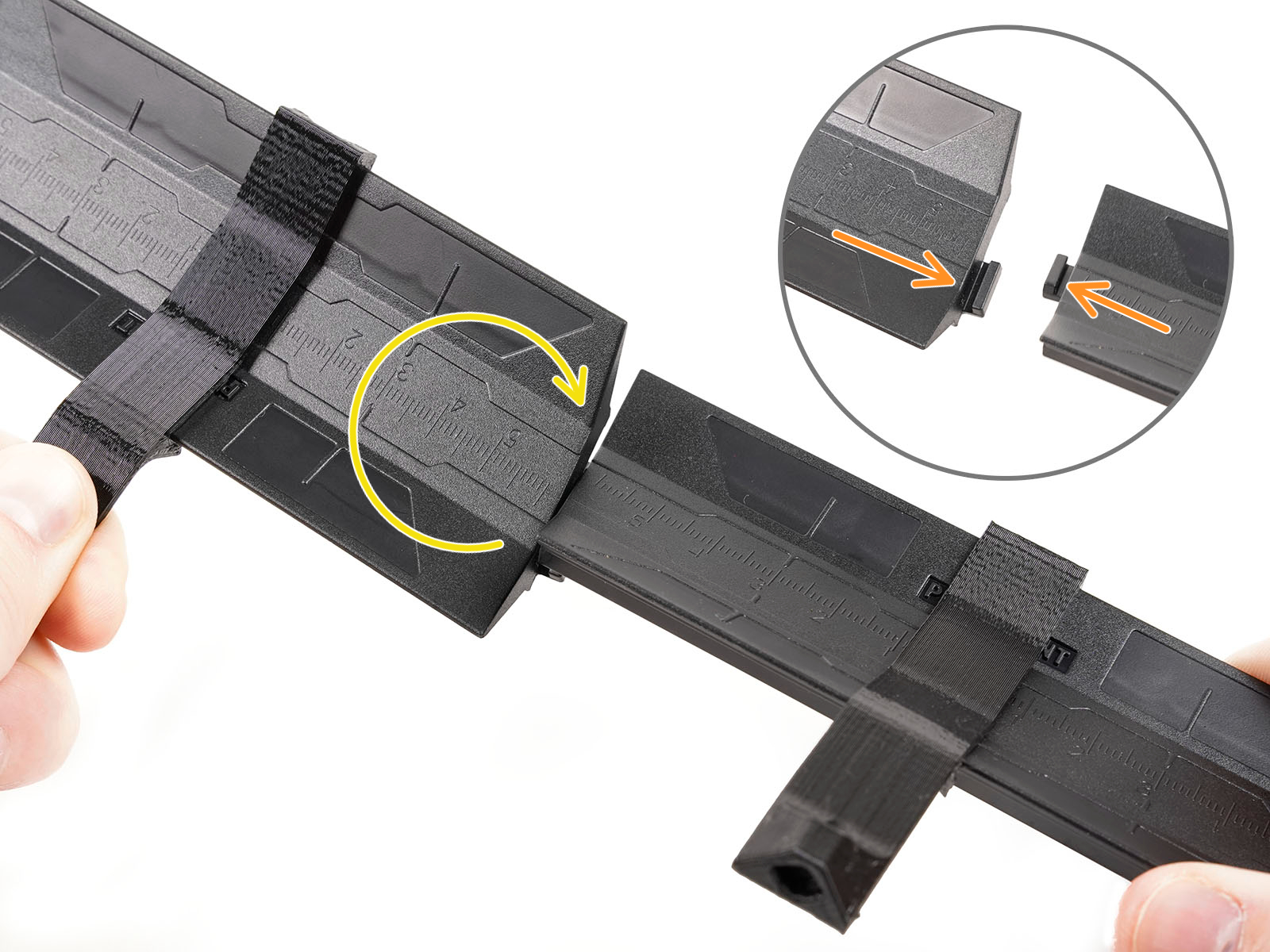

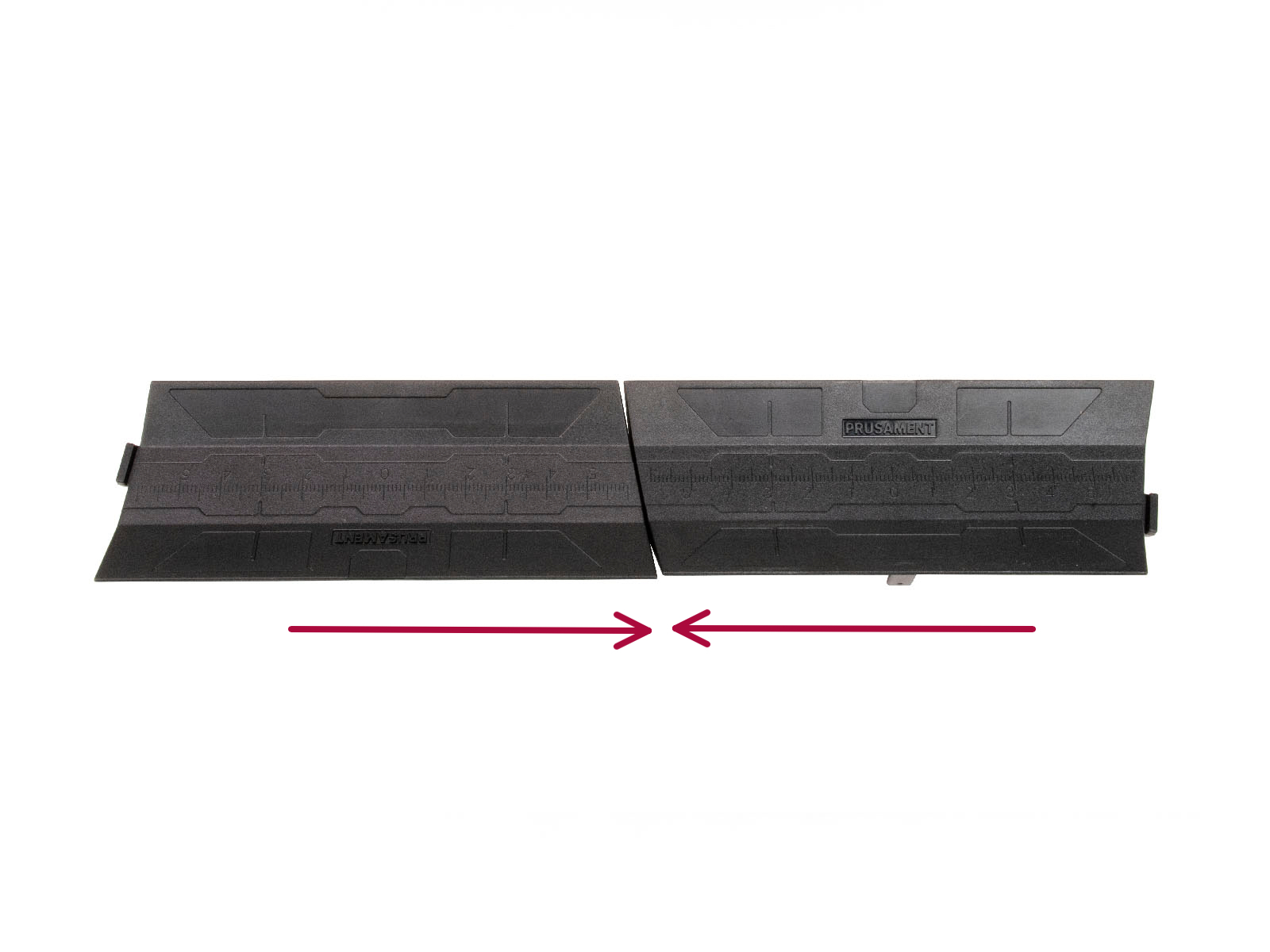

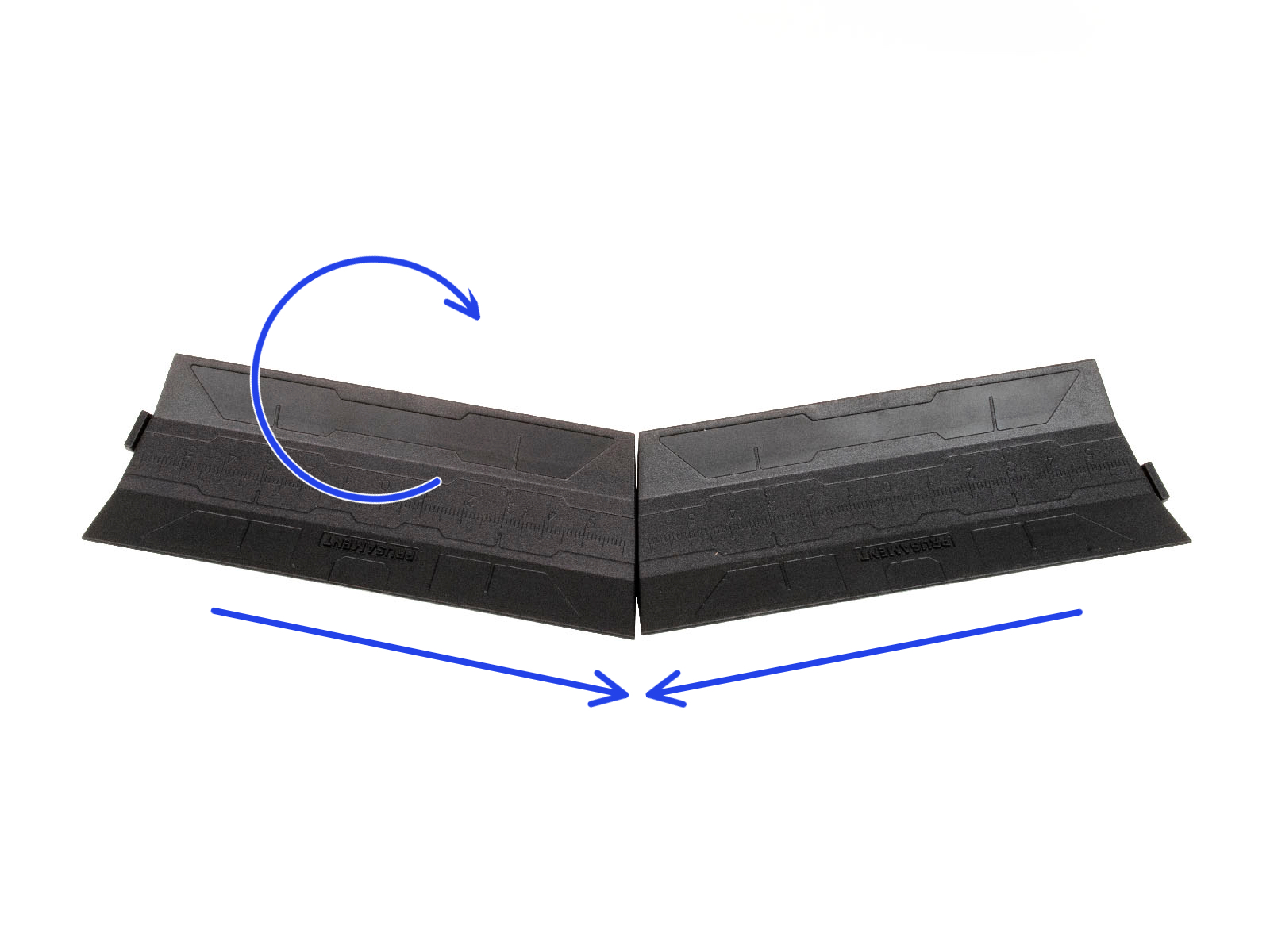

1. Classic vacuum-formed spoolholder

If you have this version, continue to the following step Vacuum formed holder parts preparation

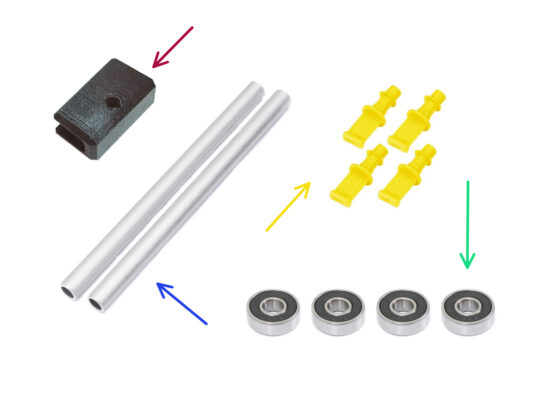

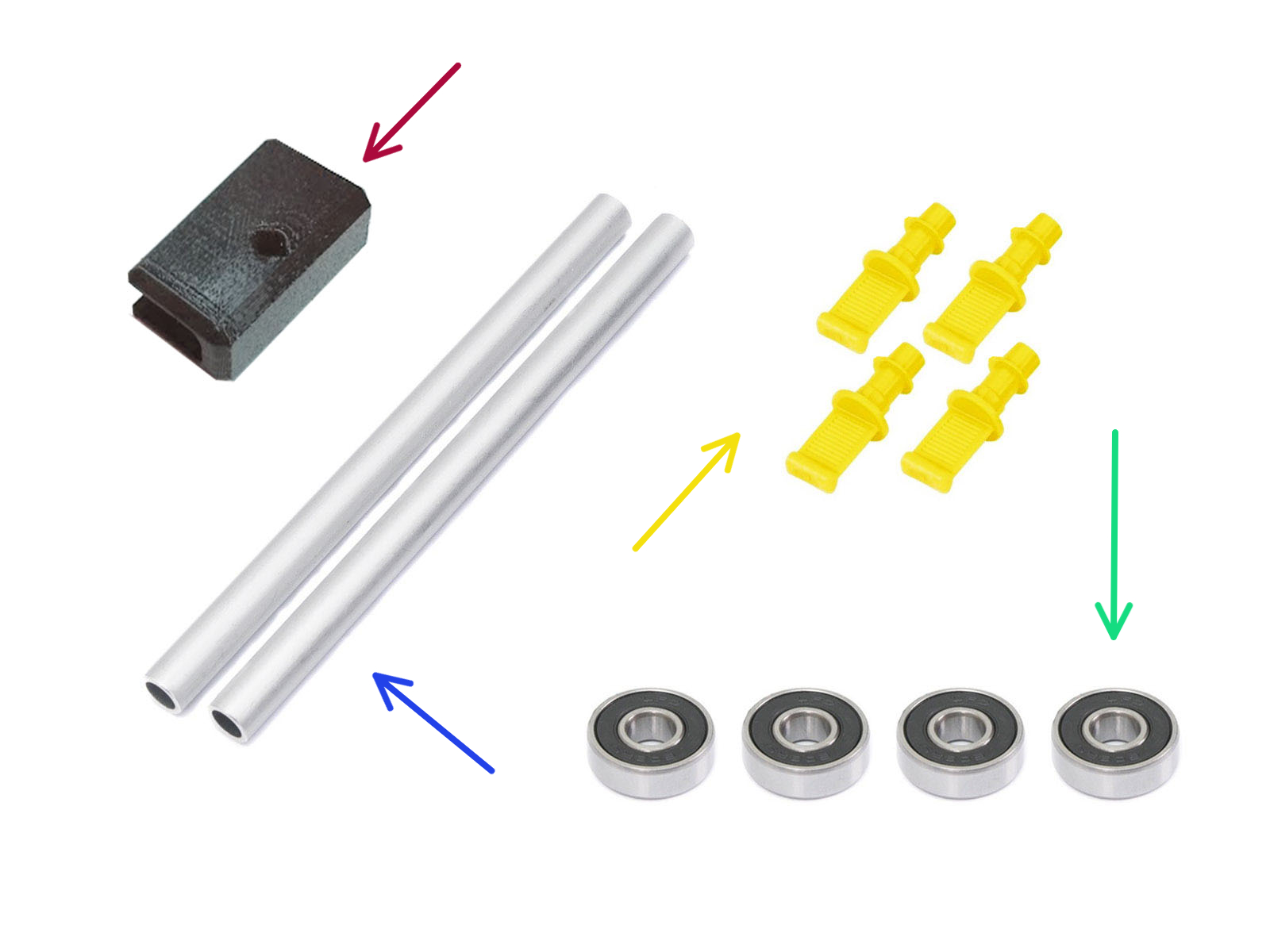

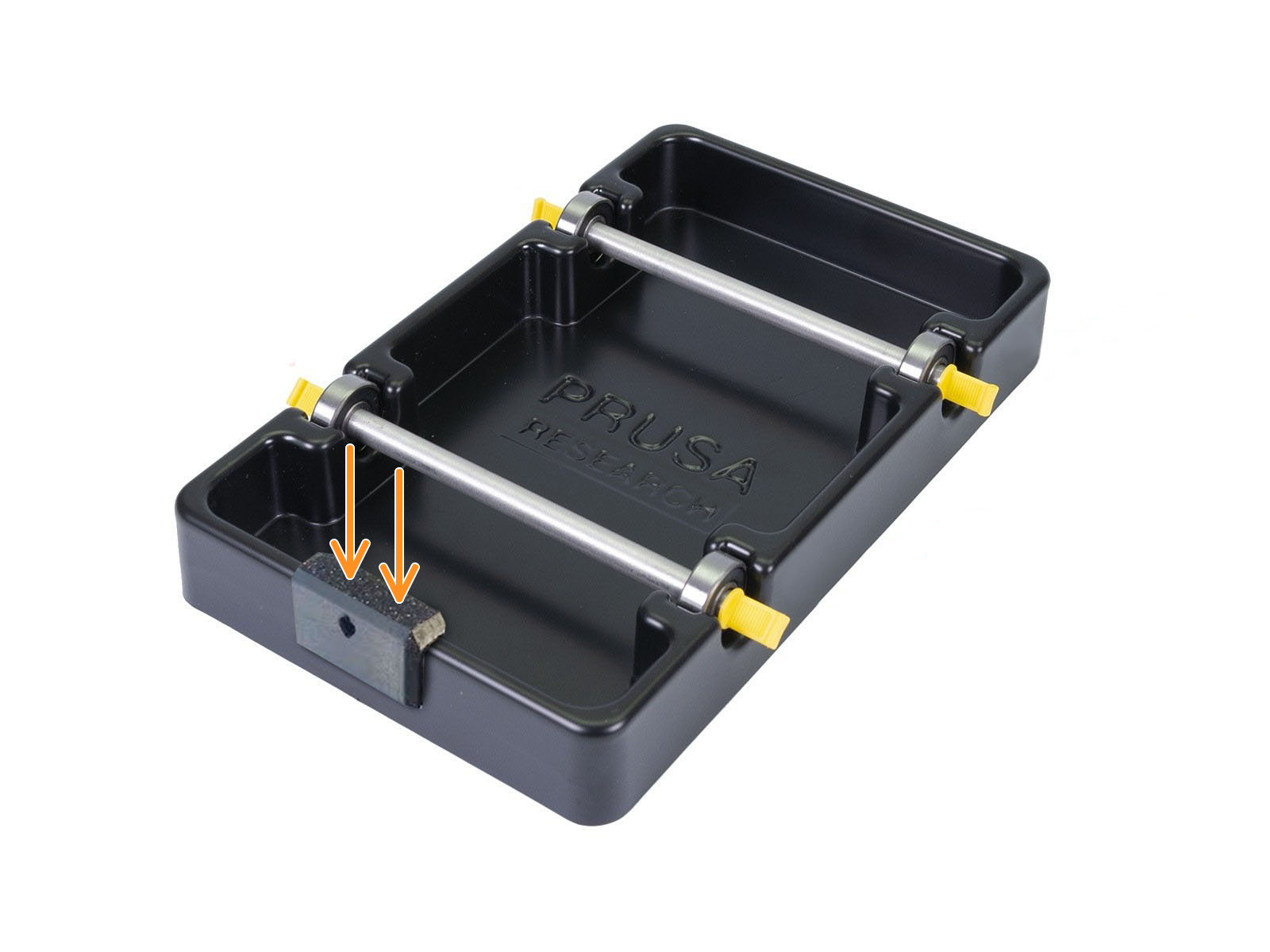

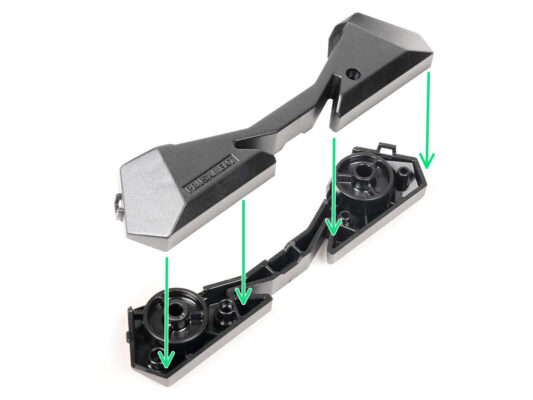

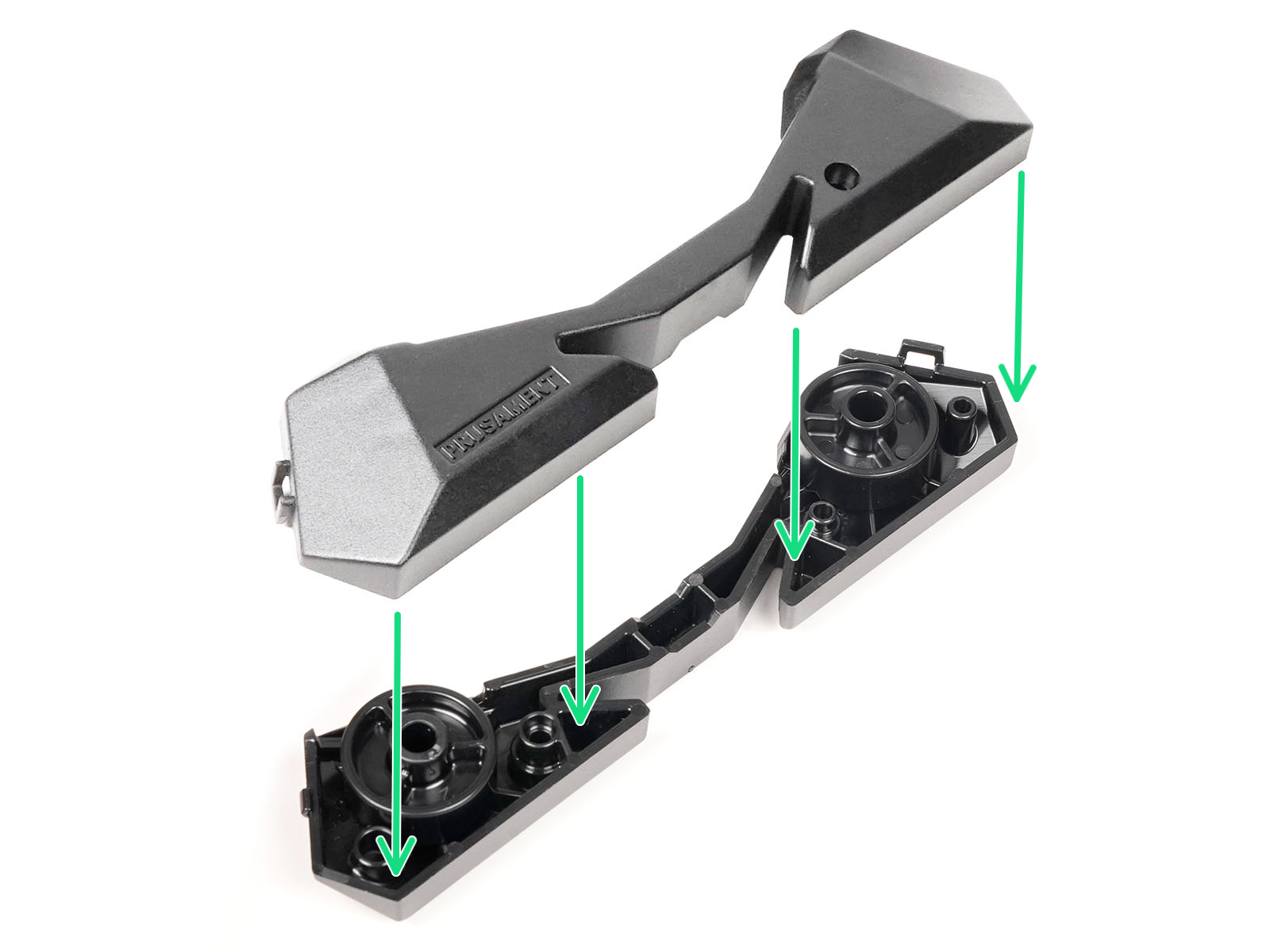

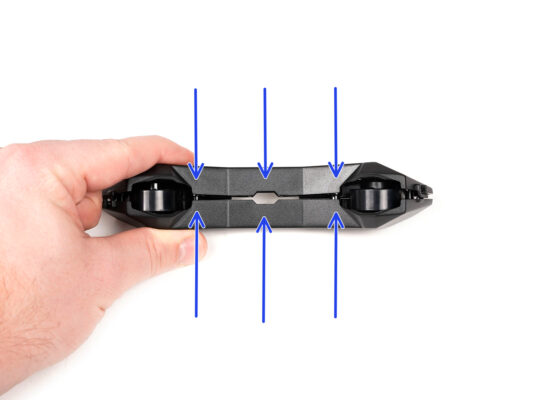

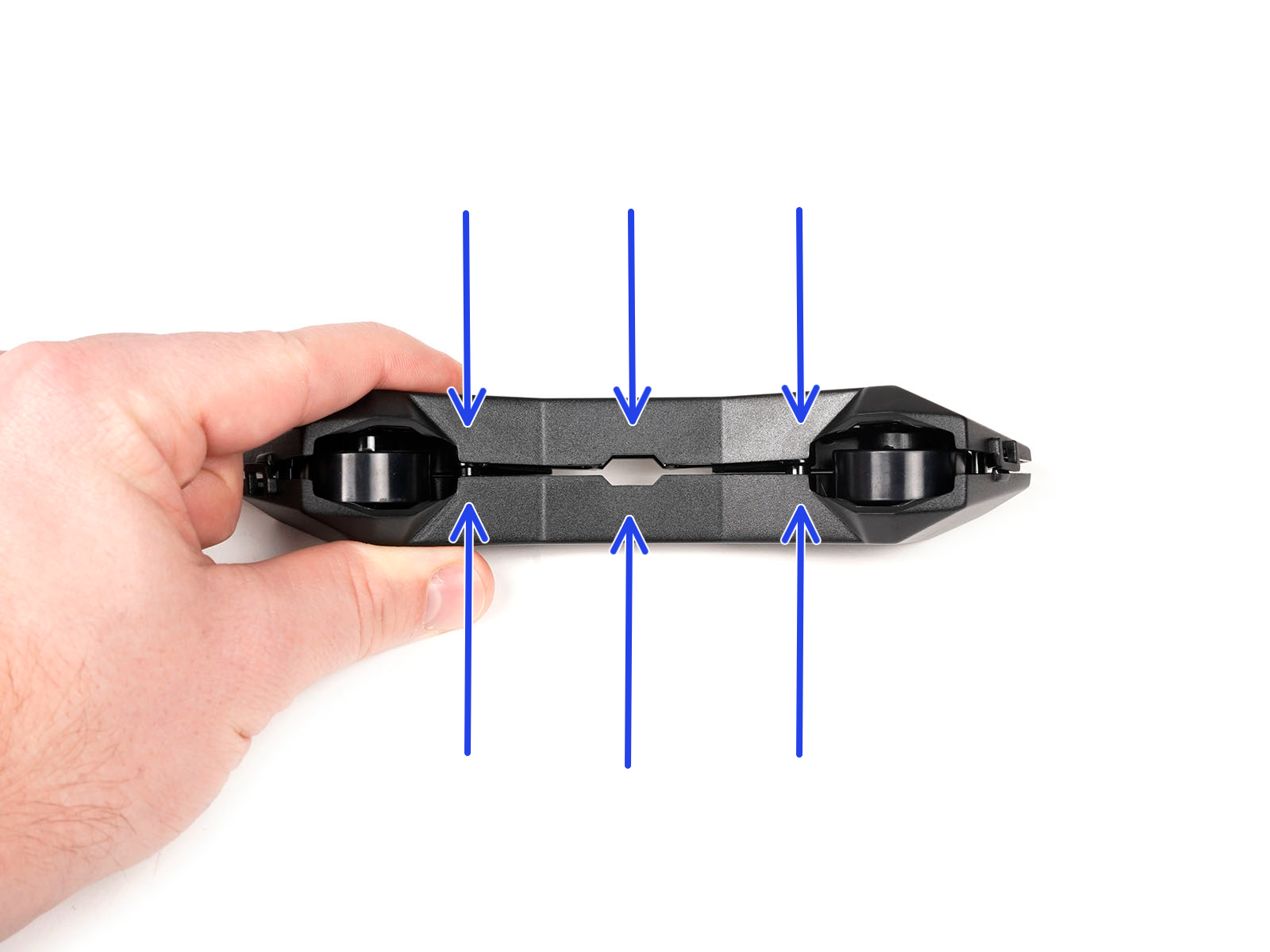

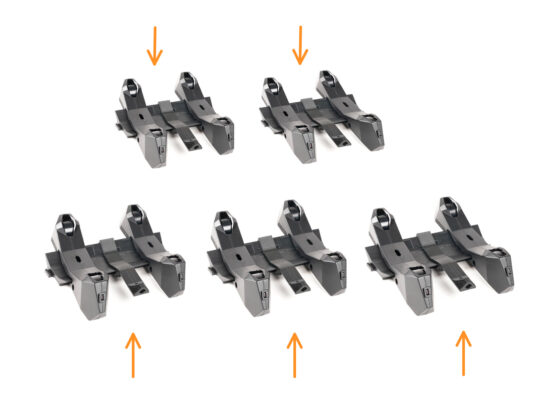

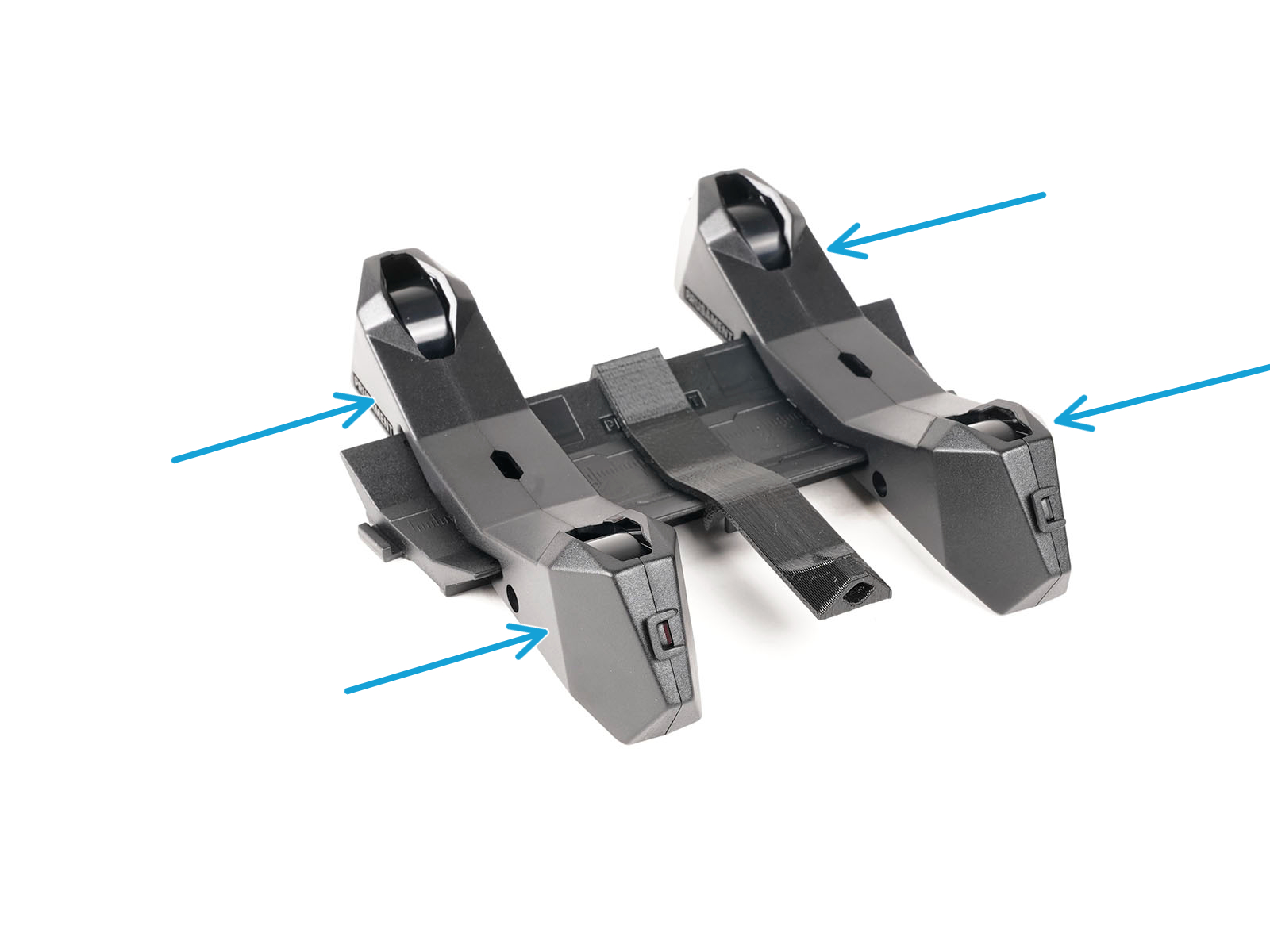

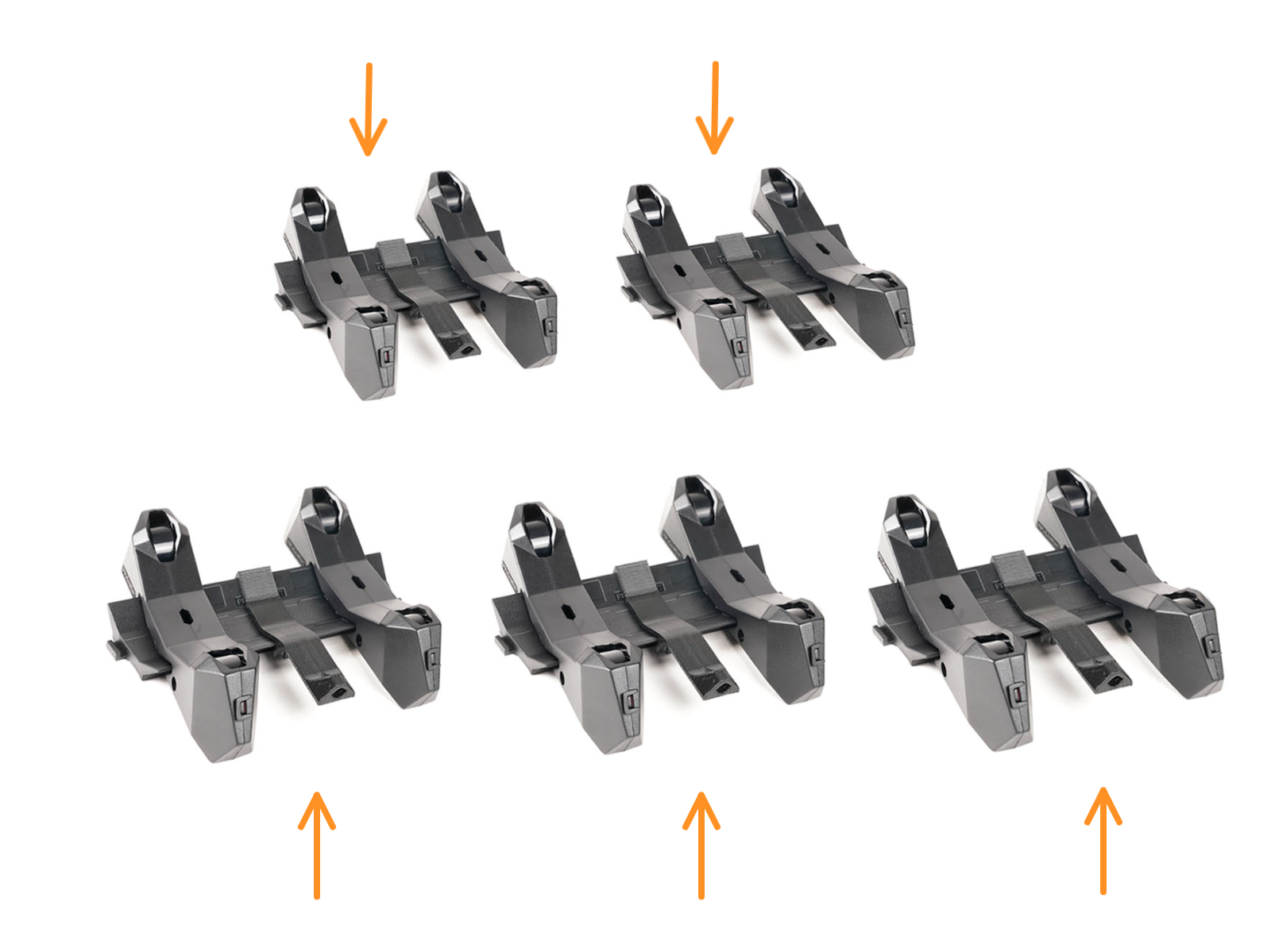

⬢2. New injection-molded spoolholder

This version comes in five packages inside a smaller box. If you have this version, skip to Injection molded spoolholder: parts preparation